5 Trends for Industrial Inkjet Printing in 2022

As industrial printers prepare for the future and evaluate production alternatives, the integration of digital printing takes on a new urgency.

Inkjet printing reduces prepress costs and make-ready waste while offering mass customization and shorter production runs. We identified these five trends and opportunities that address the fragile foundation of consumer demand and regulatory requirements.

1. Medical UDI Coding Takes on Greater Urgency

Global standards for Unique Device Identification (UDI) of medical devices and equipment have simmered on the back burner for years since Japan first introduced requirements in 1999. The United States passed legislation requiring coding in 2007.

Most countries have enacted similar regulations or are slated for implementation over the next several years. These regulations mandate UDI coding on medical devices, labels and packaging for products ranging from bandages and tongue depressors to hospital beds and implants.

With a wide range of inks suitable for digital printing the many medical products, inkjet printing stands to come out as a winner as the industry highlights the many advantages.

ADVERTISEMENT

2. LED-Curable Inks Challenge Alternatives, Offer More Benefits

E-commerce emerged as a clear winner in 2021, offering consumers a convenient alternative to traditional brick-and-mortar shopping. As retailers pivot to this new normal, they face the challenge of building customer relationships.

Digital printing offers personalization, customization and the opportunity to create a brand experience with packaging that enhances the e-commerce experience and strengthens the brand’s connection with the end consumer.

Look for eco-friendly LED-curable inkjet inks to fill this void for wide-format cardboard printing because of its many benefits over water-based inks, including:

- Weather resistance

- Excellent ink-to-substrate adhesion

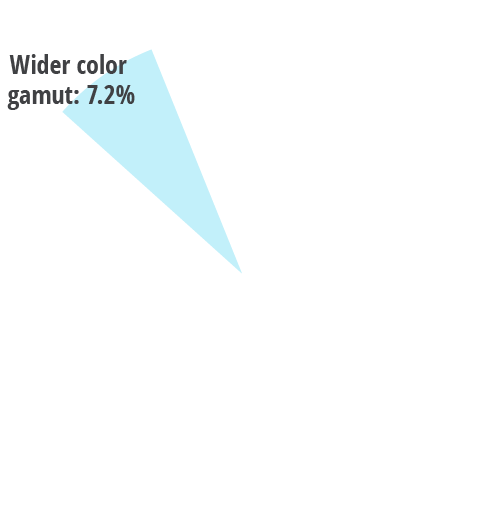

- Wider-color gamut

- Rapid curing

“While already well established for printing on flexible packaging, we’re seeing more companies choosing LED-curable inks for cardboard packaging,” according to Stephen Buchanan, Inkjet business manager at Kao Collins.

The rapid, low-heat curing makes LED inks ideal for a wide range of cardboard and label facestock, unlike traditional UV-curable ink that uses mercury arc lamps for curing. LED bulbs last longer, use less energy and don’t emit ozone or UVC radiation.

Digital printing offers personalization, customization and the opportunity to create a brand experience with packaging that enhances the e-commerce experience and strengthens the brand’s connection with the end consumer.

3. Regulations and Fraud Driving Interest in Security Inks

The primary factor driving the growth of the global security ink market is the increasing regulatory requirements involved with product tracking and the supply chain.

Pharmaceutical companies face increasing pressure to adopt security practices that comply with shifting regulations, on top of curbing fraud and counterfeiting — and they are not alone.

Many industries fight a continuing battle against counterfeiters. The cost of counterfeit products in the United States alone totals $600 billion, according to Steve Shapiro with the FBI’s Intellectual Property Rights division.

Coding and marking with overt and covert security inks makes it simpler for brand managers and regulators to identify counterfeit products.

Overt or Level 1 security printing on packaging or labels appears visibly to the eye or tactilely. Visible fluorescent inks may be used for direct coding or incorporated in intricate label designs.

For a higher level of security, covert or Level 2 printing involves invisible inks or inks with unique formulations. Verification and validation involve ultraviolet lights, infrared readers or calibrated readers, in the case of taggant inks.

Compromised products endanger and cheat consumers and brands. Look for growth in inkjet printing technology and inks for increasing security.

:: Read more about pharma security

:: Read more security inks for documents and product protection

Pharmaceutical companies face increasing pressure to adopt security practices that comply with shifting regulations, on top of curbing fraud and counterfeiting — and they are not alone.

4. Market Demands and Technology Driving Need for Fast-drying Inks

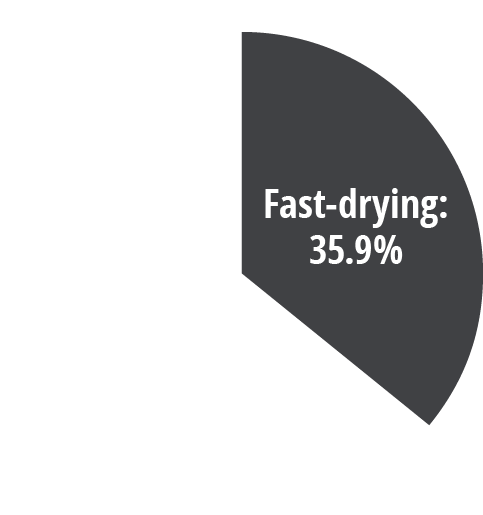

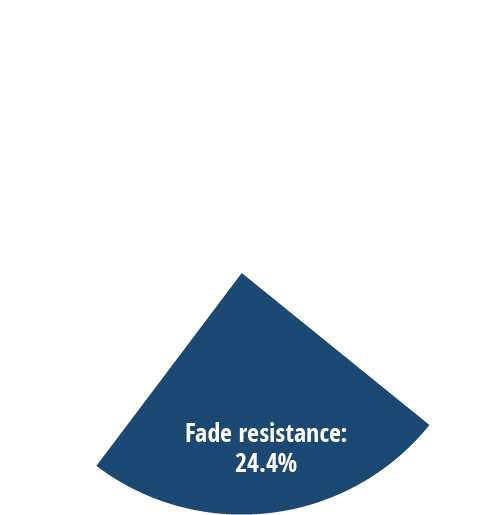

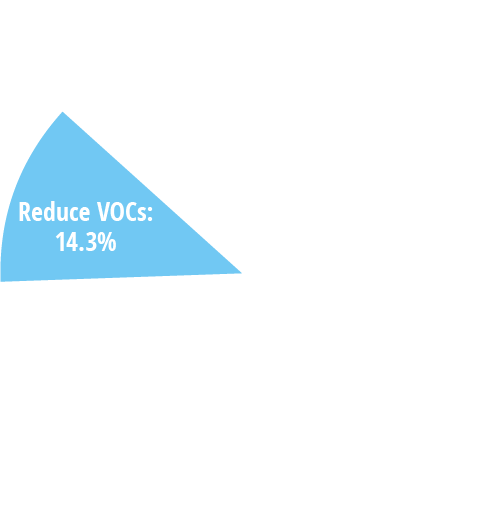

Interest in fast-drying ink outpaces other production priorities for users of industrial inkjet ink, based on analysis by DBS Interactive, a digital marketing agency in Louisville, Ky.

Market demand and squeezing more out of the benefits of digital printing are driving the need for faster printers.

The Need for Speed:

- Integration with automated production systems

- Compensating for increasing SKUs (“SKU-mageddon”)

- E-commerce market growth

- Mass customization

- Improving ROI

- Growing adoption of digital over analog printing systems

Matching inks with suitable substrates helps to achieve faster dry time. Most inks can achieve relatively fast dry time when applied to the proper materials.

Source: Kao Collins

5. Private Label Food Positioned to Compete

Grocery stores and private label brands must capture consumers’ attention to their private label food products.

The expanding private label food industry stands to win more market share in 2022, as consumers look for quality alternatives to more expensive national brands to help manage their grocery costs.

In November, the U.S. Bureau of Labor Statistics reported prices surged almost 7% for the previous 12 months. According to the Consumer Price Index, food prices increased just over 6% for the period.

Competing on price alone for food staples isn’t enough to propel sales of private label products. Consumers want premium products and a variety of flavors and packaging sizes. Brands like Aldi, HEB, Whole Foods, Kroger, Trader Joe’s and others know this.

Industrial inkjet printing offers private label food manufacturers the opportunity to produce segmented SKUs with efficiency and flexibility for brand packaging and the necessary marking and coding on shorter production runs.

In 2020, grocery brands saw three consumer groups attracted to their private label products: Gen Z, Millennials, and parents. While big brands regained some market share in 2021, the interest among these three groups reflects the elasticity of price and demand.

Combining premium food products with eye-catching packaging can elevate private label brands during inflationary periods and beyond.

:: Read more about private label food packaging

A common thread for all the trends for 2022 centers heavily on packaging, one of the fastest-growing segments of industrial inkjet printing, along with label printing.