RETORT PACKAGING GETS ECO-FRIENDLIER

Retort packaging builds its green credentials via recyclable retortable pouches and new machinery that reduces energy consumption and therefore carbon footprints.

By Brad Addington

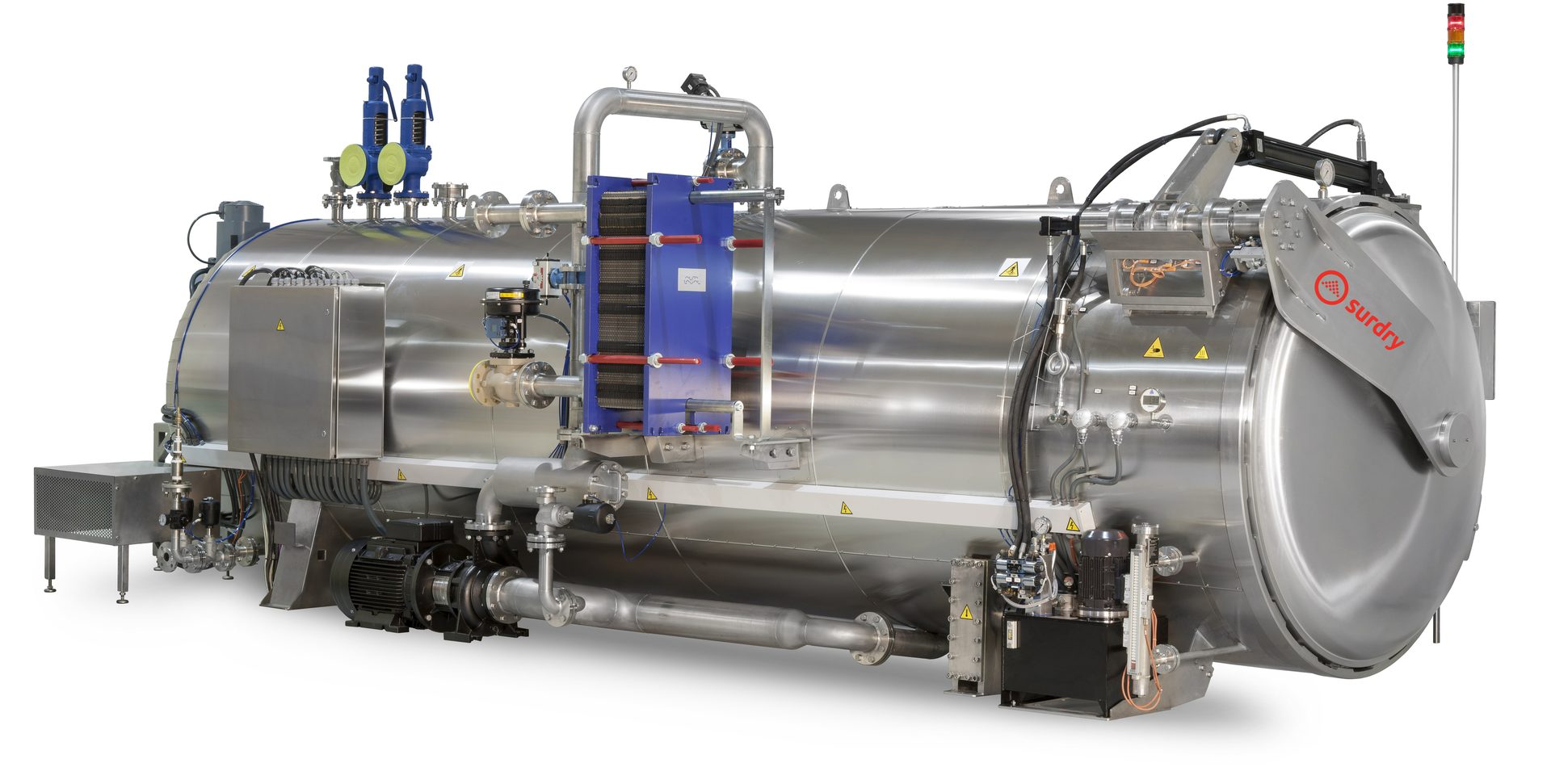

Courtesy of Surdry North America

This story looks at recent developments that have rendered retort equipment more efficient and retort packaging more eco-friendly.

However, before delving into those specific areas, it’s worth stepping back and taking a broader view of the retort packaging market.

Market research firm The Brainy Insights estimates that the USD 4.2 Billion Retort Packaging market will reach USD 7.7 Billion by 2033. “Rising growth in the pharmaceutical industry and rising growth in online food ordering may fuel the growth of the Retort Packaging Market,” the firm notes.

North America has emerged as the largest global Retort Packaging market, accounting for 57% of the total market, owing to “increasingly busy work life, lack of work-life balance, increasing disposable income in the hands of the common man,” the firm notes. Meanwhile, the Asia Pacific region exhibits the highest growth rate in the market owing to rising demand for convenient products, and rising demand for ready-to-eat foods.

The Pouch segment has dominated the retort packaging market, accounting for 54% of the total market.

With regard to more eco-friendly retort packaging, the firm notes that, in April 2023, Huhtamäki Oyj introduced three unique solutions in mono-material flexible packaging. These solutions are specifically designed with recyclability in focus, aiming to minimize resource consumption during production. The primary goal of this launch is to offer users environmentally friendly and flexible packaging alternatives in Paper, PE (Polyethylene), and PP (Polypropylene) Retort formats.

In this story, we look at two retort heavyweights — Surdry North America and Allpax — in the context of initiatives to produce retort packaging that is more eco-friendly and to supply retort equipment that operates more efficiently, thereby reducing greenhouse gas emissions.

SNA presents exclusive Continuous Sterilizer solution at PACK EXPO East

Surdry North America (SNA) showcased its cutting-edge Continuous Sterilizer solution at PACK EXPO East from March 18-20 in Philadelphia, Pa. Visitors learned about Surdry’s exclusive technology that promotes steam consumption savings by 30-40%, leading to significant energy cost reductions. The new, patented technology enables simultaneous processing of diverse container types, including cans, jars and pouches, in the same equipment.

Attendees also learned how they can take advantage of SurdryUP, SNA’s support program created to minimize unplanned downtime and maximize OEE levels.

READ MORE

With SurdryUP, every Surdry retort installed within the U.S., Mexico and Canada is eligible to receive a free, annual preventative maintenance analysis. SNA technicians will conduct visits to identify parts that need replacing, review inventory levels, provide maintenance recommendations and suggest operational improvements to increase performance and safety.

Surdry experts were at the show to discuss retort technologies with visitors and offer support to those seeking ideal solutions to reach their business goals.

“We’re excited for our debut in Philadelphia and eager to connect with both current and new customers, exploring ways to enhance their operational efficiency and cost-effectiveness,” said Adriana Farris, product manager at SNA, prior to the show. “The conversations we have at trade shows are invaluable and allow us to help customers navigate through complex processes, like selecting the right sterilization technology or packaging materials tailored to their products. We are thrilled to be able to share our insights.”

PACK EXPO East is a leading show on the East Coast for packaging and processing professionals, helping attendees identify modern technologies, meet key partners and explore innovative solutions. This year’s show brought together 7,000 industry professionals to the Pennsylvania Convention Center in Philadelphia.

Representatives of Surdry North America present retort solutions at a trade show.

Courtesy of Surdry North America

COLLAPSE ARTICLE ABOVE

Recyclable Retortable Pouches: Understanding Three Key Concepts

Lightweight, compact and heat-resistant retort pouches are a smart choice for food products requiring retort sterilization to ensure extended shelf lives. This includes baby food, ready-to-eat meals and pet food.

Despite consumers’ growing concerns about the environmental impact of packaging waste, limited recyclable retort pouch options are available in the market as brands explore sustainable solutions.

Surdry North America (SNA) has summarized three essential points about recyclable retort pouches in the food industry:

READ MORE

- What is the material difference between regular and recyclable retort pouches? Traditional retort food pouches are typically multi-layered, made from a combination of polypropylene (PP), aluminum foil and polyethylene (PET). These materials are used for their durability to withstand high temperatures and pressures from the retort process, ensuring a longer shelf life.

However, they raise an environmental concern: When laminated together, these materials cannot be separated during the recycling process nor sorted appropriately within the recycling stream. Brands have been testing different technologies to create recyclable options that are resistant to the retort process, while also maintaining product quality. Many have achieved positive results by utilizing a mono-material, commonly PP film, which can be melted and re-formed into new products. - How sustainable are the recyclable options? Various factors can affect the environmental impact of recyclable, heat-resistant pouches. In general, pouches help reduce material usage and lower the carbon footprint in production and transportation compared to sustainable rigid packaging formats, like glass.

Sustainable retort pouch materials are easier to recycle than those typically used in regular ones. However, consumers face challenges in recycling mono-material pouches properly, forcing them to use store drop-off recycling programs rather than curbside bins. The recycling infrastructures and processes in the cities must be prepared to handle these types of packages. - Why aren’t these pouches widely used in North America? Recyclable retort pouches face obstacles in penetrating alternate markets due to their market novelty, high production costs, limited material availability and insufficient recycling infrastructure. And although more sustainable, their appearance may not match that of non-recyclable pouches, posing a challenge in attracting customers.

Brands have been trying different approaches — including the utilization of mono-material films — to create recyclable retort pouches that are resistant to the retort process.

Courtesy of Surdry North America

COLLAPSE ARTICLE ABOVE

Allpax Identifies the Seven Warning Signs of Retort Control System Obsolescence

Allpax, a ProMach brand, has identified the seven warning signs of control system obsolescence in batch retorts. Modernizing outdated and failing control systems improves retort uptime, product quality, ease of use and maintenance, and access to data, while lowering the risk of product recall.

“As long as the shell and door(s) of the batch retort are sound, a control system update can prolong the life of the unit for years, while improving output and product quality,” said David Cohen, Director of Software Engineering.

Cohen said Allpax sees an increase in requests for modernization of older vertical and horizontal retorts/autoclaves and also receives requests from process authorities who want newer retorts, regardless of brand, to have the ease of use and functionality of the latest Allpax software.

READ MORE

The seven warning signs of control system obsolescence are:

- Replacement parts only available on the used market

- Erratic temperature and pressure control conditions during processing

- Waste becoming unsustainable

- Data access and display challenging for process authority personnel

- Controls difficult to learn and use

- Decreasing number of maintenance personnel who can troubleshoot and maintain the retort

- Downtime increasing and output falling

A first step in control system modernization can be a retort shell integrity and control system audit conducted by Allpax software and mechanical engineers. They can ascertain the operational effectiveness of key mechanical components, including valves, actuators, instrumentation, and motors/drives.

Then Allpax will prepare an action plan and a proposal for the recommended upgrades or replacement components. At a minimum, the PLC, HMI (human machine interface) and server will be replaced with off-the-shelf, easily obtained components. Whether components such as instrumentation, valves, and actuators will be replaced depends on their age and performance.

New control panel(s) are built and pre-wired at the Allpax facility in Covington, Louisiana, and/or Allpax will make updates on-site to the existing control panel. Allpax also provides on-site start-up, commissioning, training, temperature distribution testing, and production support as needed.

Freshly installed components deliver the performance and ease-of-use characteristics of the latest industrial technology. Allpax control software complies with FDA processing guidelines, including 21 CFR Part 11. Allpax software can be configured to print reports following each batch and thus eliminates the need for handwritten batch records. Process authorities will find the type of data and ease of access and display will meet or exceed all modern standards and regulatory requirements.

Allpax recommends that every modernization project integrate the company’s basket tracking system. Basket tracking ensures that every product basket enters the correct retort and that no basket bypasses sterilization. This system lowers the risk of product recall. New control systems also facilitate remote technical access to the batch retort. Real-time technical assistance from the people who built the system can reduce downtime from days to hours.

“Allpax brings retorts from the past into the present,” Cohen said. “We can’t remember any modernization during Allpax’s 38-year history where a customer wasn’t thrilled to prolong the life of their existing retort assets and have the benefits of current technology.”

For more information, contact David Cohen, Chris Barbier, Jeff Arthur or Scott Williams at Allpax and visit the company’s website for its lineup of products and services.

Allpax has identified seven warning signs of control system obsolescence in batch retorts.

Courtesy of Allpax

COLLAPSE ARTICLE ABOVE

Allpax delivers high-speed pouch loading system to feed retorts

Allpax, a ProMach brand, recently delivered a new high-speed automated pouch loading and unloading system to a customer to feed an existing bank of Allpax retorts.

“A world-leading contract packing operation struggled with manual loading and unloading of pouches for more than a year,” says David Cohen, Director of Software Engineering at Allpax. “The operation experienced excessive damage to pouches and trays, as well as not meeting output requirements. The Allpax automated pouch handling system solved these issues.”

READ MORE

At the load cell, the fully automated system uses Delta robots to orient and form a pattern of unprocessed pouches, and then uses 6-axis robots to pick and place full patterns of pouches onto self-stacking trays at a rate up to 200 pouches per minute. A secondary 6-axis robot is used to stack the trays on top of each other, and then the tray stack is conveyed out to an existing shuttle system that feeds the retorts.

After the pouches have been retorted, the shuttle transports the tray stacks to the unloading cell. Trays are de-stacked by a 6-axis robot, and the full pouch pattern is removed from the tray by another 6-axis robot and placed onto a mass take-away conveyor.

As the pouches are moved down the mass conveyor, one row of pouches is discharged at a time to form a single lane of pouches, which are then sent to the packaging line. The 6-axis robot flips empty trays over to ensure there aren’t any remaining pouches. The robot then re-stacks the empty trays so that complete tray stacks can be automatically returned to the load cell for use in loading the next batch of unprocessed pouches. Full automation maximizes output while reducing headcount in the retort room and lowers the risk of damage to the packages and trays compared to manual loading and unloading operations.

This scalable and customizable system integrates the robotic tray loading and unloading cells with an automated tray tracking system to ensure unprocessed tray stacks of pouches can’t be sent to the unloader cell without being fully processed in the retorts. The latest generation of Allpax automation controls are employed and are fully integrated with the retort process controls.

Intuitive human machine interfaces (HMIs) make learning, operating, and maintaining the system a breeze. Like the equipment described above, the control system is designed and manufactured at the Allpax facility in Covington, Louisiana, and uses off-the-shelf components for ease of replacement and serviceability. The Allpax engineers who design and build the system also support it, thus providing customers with knowledgeable and expedient help when needed. Customers can opt for 24/7 remote-access technical support for even quicker assistance, thus minimizing equipment downtime.

For more information, visit the company’s website for its complete lineup of products and services.