Labels Go Digital

Paul Edwards of INX International explains why digital label printing is gaining steam. Reasons include improved image quality, embellishment options, and digital chipping away at certain analog advantages in terms of economic run lengths.

By Brad Addington

In the early days of digital label printing, one of the main reasons for switching from analog to digital was short-run economics. Digital printing meant it was no longer necessary to over-manufacture labels to be able to run a very short job economically. The early focus was on short-run economics and mostly on industrial labels rather than prime labels due to early quality constraints.

However, technological advancements have provided additional incentives for switching from analog to digital when it comes to printing labels. We recently sat down with Paul Edwards, Vice President of the Digital Division at INX International Ink Co., to find out why digital print could potentially grow to 15% of label sales in 2025.

PS: We’ve written extensively about the advantages of digital printing for brand managers, such as the ability to easily personalize brands through digital printing. What are some of the key advantages of digital printing when it comes to labels?

PAUL: Regarding the advantages seen by brand managers, I think there has been very good progress in recent years with regards to awareness. This will become a strong driver for continued growth in digital print going forward. But when you consider the growth over the last couple of decades — from first implementation until now — I would say these were not the main drivers.

The label industry in general is a competitive place, and economics is a significant factor. In the early days of digital printing labels, the main drivers were purely short-run economics. You no longer had to over-manufacture labels to be able to run a very short job economically. Leaving labels on the shelf hoping for future sales is an inventory cost. The early focus was short-run economics and mostly on industrial rather than prime labels due to early quality constraints.

ADVERTISEMENT

Outside of the short-run economics, the ability to print on demand and reduce the lead times of these smaller runs was an attractive competitive advantage. Versioning, which is a common requirement, was also a driver for short-run digital and was more available to end customers in an economic manner. Development of the current analog printing process also took place to compete with the new digital challenge. Over time, digital started to chip away at certain analog advantages in terms of economic run lengths, the quality of images suitable for prime labels, and the various embellishments to make labels more appealing, whether this was carried out via digital solutions or by a hybrid analog-digital approach.

The label industry has been driven by economics and the ability of digital systems to make money for the label producer. Looking ahead with the fact that brand managers are now understanding the full impact of digital, there will be a pull to create more opportunities for digital print. There will be a value for these capabilities, and where there is value, there will be money to be made.

PS: Do you have any figures or statistics (or anecdotal evidence) that speak to the growth of digital label printing?

PAUL: Yes, there are many studies available to research on the projected growth of the digital label market. Our marketing group at INX has evaluated many of them. When focusing on the North American market, there are estimates of an overall 8.6% CAGR in the value of digital print between 2022-2027, with the United States at 6.6% CAGR during that period and Canada at 9.1%.

It is interesting to note forecasts showing that in 2025, digital print should grow to 15% of label sales. This would be an increase of 96% when compared to 2017. There is certainly plenty of interest in the market, and although there has been a reduction in the number of companies supplying digital label presses, there is still plenty of investment in new products and in areas where inkjet still needs further development, such as embellishments.

It is interesting to note forecasts showing that in 2025, digital print should grow to 15% of label sales. This would be an increase of 96% when compared to 2017.

"It is interesting to note forecasts showing that in 2025, digital print should grow to 15% of label sales. This would be an increase of 96% when compared to 2017."

INX has produced labels for many different market segments, including the wine and spirits industry.

Courtesy of INX International Ink Co.

PS: On the flip side of that last question, are there any reasons that some parties are reluctant to switch from conventional printing to digital printing when it comes to labels? If so, how does INX address those concerns?

PAUL: There are several reasons why there can be some reluctance in moving to digital printing on labels. I suspect some relate to the size of the business. However, reasons may include, for example, investments in current analog printing have already been made. Or perhaps the equipment is fully depreciated, and thus they have a low-cost base for manufacturing and are reluctant to add new investments. This would be a larger issue for the smaller printers.

Label printers vary greatly in both size and market focus. If a company has optimized and can produce low-cost, long-run labels, the benefits may be less impactful at this time. There may be a reluctance to move to digital due to the different nature of the technology and concerns about learning something new, especially in the areas around pre-press but also in terms of running and maintaining the equipment. Some people may also be concerned with digital equipment becoming outdated quickly and the need to upgrade more regularly.

At INX we have many years of experience with regard to digital printing and printing systems. We can help recommend equipment best suited for a customer in their own unique situations. We also have an experienced technical service organization which can advise customers on aspects of color management they may not be familiar with.

We provide high-quality performance inks and certain printing systems for the label market, and we can advise on the performance of different ink products. I think it also helps to explain the benefits which are current today, and the secular drivers of a brand and for end customers which will encourage further growth in digital products. That said, digital will not be the correct solution for everybody in their unique situations. We understand and appreciate this fact.

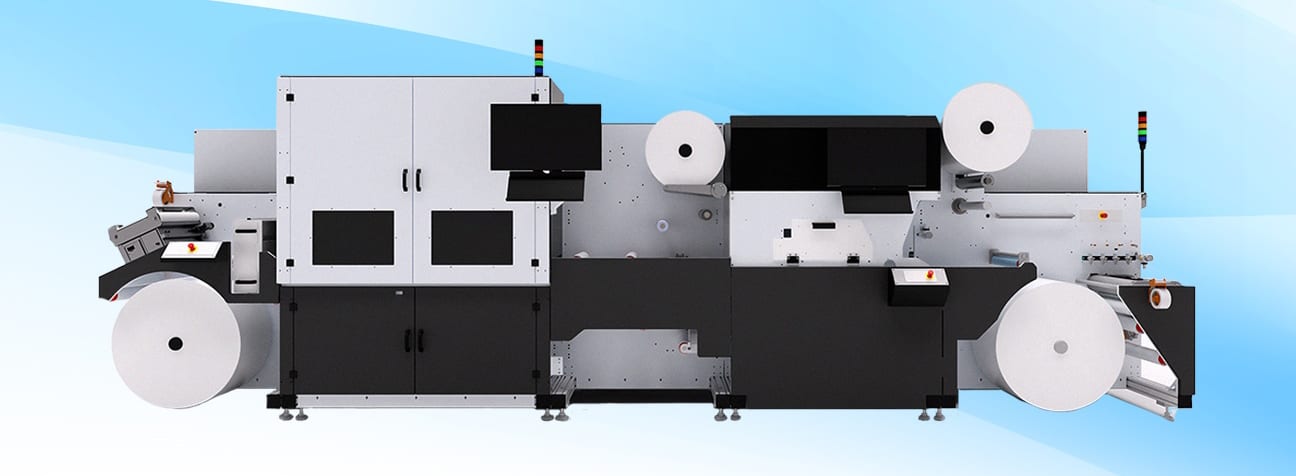

The INX NW 350 printer combines printing and conversion to produce brilliant color labels at outputs of up to 160 per minute on any label stock.

Courtesy of INX International Ink Co.

PS: We report regularly on technological advancements in packaging and printing. What are some game-changing technological developments in the realm of digital label printing that you have seen, and what are some of the technological developments that you foresee going forward?

PAUL: Printing systems have come a long way in the last five years. We are now seeing great print quality with decent speeds that increase the run length to where a job will be profitable in digital. Many advances today are more iterative and related to continuous improvement.

One interesting area relates to the wider systems which can print narrow web flexible packaging as well as labels. This increases the addressable market for the printer. Another area relates to embellishments, where digital is coming out with systems capable of digital foil production. Spot gloss effects are also becoming more popular. The advance of hybrid systems — where there is a mix of digital print as well as analog embellishments — is a good step forward in getting the best of both worlds.

The ability for a system to also implement laser die cutting can be a real benefit to some customers. Looking ahead, I expect to see developments in both substrate and ink related to the secular sustainability theme. I also believe products that provide regulatory benefits, such as low migration, will become important, especially when using LED curing systems.