Package of the Month

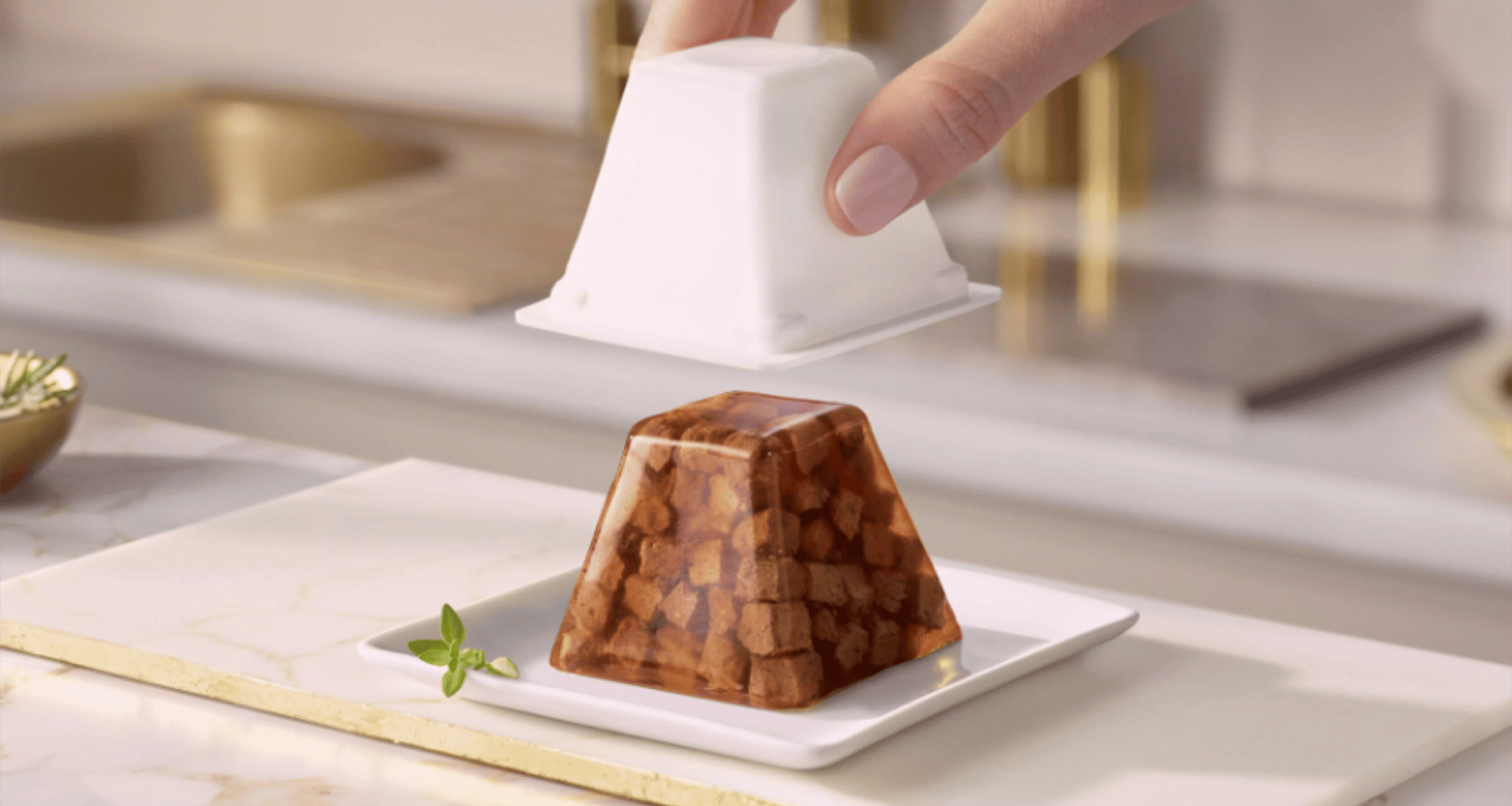

Nestlé Purina Petcare Unveils New Cat Food in Pyramid-Shaped Packaging

Developed after years of research and behavioral studies, the Gourmet Revelations Fine Cuts in Gelée was designed to encourage natural wide bite/lick-bite/lick/chew behaviors.

Nestlé Purina Petcare has announced the release of its new Gourmet Revelations Fine Cuts in Gelée, ideal for cats of all types. This innovative cat food, set to delight refined felines and their owners, features a combination of delicate transparent jelly and finely diced tender cuts, a first-of-its-kind offering from Purina.

Available in 57-gram pots and two varieties, Chicken and Salmon, the Gourmet Revelations Fine Cuts in Gelée is packaged in multipack sizes of two, four, and 48 pots. The range, known for its elegant pyramid packaging design, aims to provide an exquisite serving experience with high-quality ingredients.

The user-friendly packaging pots ensure easy release and minimize spillages, catering to owners who seek to bond with their feline companions during mealtimes.

The new cat food is available in packages of two, four, and 48.

Sareena Kainth-Patel, Senior Brand Manager for Gourmet, said: “With the announcement of Gourmet Revelations Fine Cuts in Gelée, we’re happy to be revealing and celebrating the unique personalities of cats across the nation, as well as unveiling a new texture experience, ensuring our pets get to enjoy mealtime just as much as their owners do.

“Owners actively seek ways to show love and affection towards their cats - seeing them admire and savor their food is a crucial part of that. We’ve undertaken extensive research to develop a product which is perfectly shaped to create the ultimate feline foodie ritual. In addition, our patented packaging design is truly unique in the category and helps to elevate the serving experience for pet owners who want to pamper their feline companions.”

Gourmet Revelations Fine Cuts in Gelée is being rolled out across stores nationwide from this month.

Courtesy of Nestlé

Mondi and Sherwin-Williams Develop Refill Stand-Up Pouch for Concentrated Paint

Mondi, a global leader in sustainable packaging and paper, collaborated with Sherwin-Williams, a global leader in paints and coatings, to introduce re/cycle SpoutedPouch as a refill option for its concentrated paint, sold on the UK market. Leveraging the expertise in its Halle/Steinfeld plant in Germany, Mondi introduced a wider spout for easier filling and pouring, while ensuring the mono-material pouch is designed to protect its contents.

The paint concentrate was developed to replace the traditional 5-liter pre-mixed paint in rigid plastic tubs. Consumers are encouraged to reuse these tubs to mix the paint concentrate and then recycle the refill’s packaging. It comes in a lightweight 950ml spouted pouch with instructions for mixing clearly printed on the side. The spout offers excellent pourability to make it easy to mix with water and create the needed amount of paint. The pouch can be tightly closed after usage, preserving any unused concentrate.

Mondi worked closely with Sherwin-Williams to deliver a solution tailored to their specific packaging needs. re/cycle SpoutedPouch is a pre-made pouch made from polyethylene mono-material and has a wider spout making it easier for Sherwin-Williams to fill the paint concentrate. Mondi’s SpoutedPouch reduces packaging waste and provides ease of use to outdoor painting projects, along with minimizing the space needed to transport and store paint.

The condensed size compared to regular 5-liter pre-mixed paint tins means 230% more units can fit on each pallet, resulting in increased efficiency within the supply chain. The pouches also take up less space on retail shelves and come packaged in shelf-ready tear-front boxes of five units, allowing easier stock replenishment compared to traditional tins.

Ronseal concentrated fence stain in a pouch is now available online, at DIY markets and through retailers across the UK.

Courtesy of Mondi

Viva Energy Transforms Used Cooking Oil into New Chip Packets

In a demonstration of the broad value of the Geelong Refinery to Australia’s economy, Viva Energy has announced that it has produced its first ISCC+ certified mass balanced bio-based polymer (recycled food-grade plastic) following the successful processing of a batch of used cooking oil (UCO) at the refinery.

It is the first time UCO has been utilized to create bio-based polymers though the Geelong refinery’s catalytic cracker and adjacent polypropylene plant.

The UCO came from Intersnack ANZ in New South Wales where it had been used to cook some of Australia’s favorite snacks like Kettle Chips, CC’s, Natural Chip Company, Thins and Cheezels. Later this year Intersnack ANZ will use this ISCC+ certified mass balance bio-based material to create plastic packaging for some of its products. This represents an exciting development for Intersnack ANZ in its efforts to build strong partnerships, support local innovation, and to reduce its environmental footprint.

This is an important step in creating a circular economy using feedstocks made from waste and complements Viva Energy’s plastic recycling project with Cleanaway. This initiative could provide significant sustainability solutions for food and packaging manufacturers in advance of a new regulatory recycling scheme proposed by the Australian Government.

Cleanaway collected and processed the UCO to remove any impurities before it was delivered to the Geelong Refinery for processing. Viva Energy has invested in upgrades at the refinery to allow the injection of these alternative feedstocks into its complex infrastructure.