PACK EXPO Vegas: A Preview

Get on track with tips for the show and exhibitor previews.

By Kristin Joker

September 27 – 29, 2021

Las Vegas Convention Center

Las Vegas, Nevada USA

Monday – Tuesday, 9:00 am – 5:00 pm

Wednesday, 9:00 am – 3:00 pm

PACK EXPO Vegas: A Preview

Get on track with tips for the show and exhibitor previews.

By Kristin Joker

September 27 – 29, 2021

Las Vegas Convention Center

Las Vegas, Nevada USA

Monday – Tuesday, 9:00 am – 5:00 pm

Wednesday, 9:00 am – 3:00 pm

PACK EXPO Las Vegas and the co-located Healthcare Packaging EXPO, presented by PMMI, the Association for Packaging and Processing Technologies. The event includes:

Full-scale machinery — in every hall of the convention center — buzzing with packaging and processing machinery in action

Top advances and solutions in packaging and processing, sustainability, packaging materials, automation, robotics, printing, etc.

Educational sessions and discussions in several venues around the show floor connecting people and ideas

Pavilions focusing on solutions in the categories of containers and materials, confectionery, digital printing, processing and reusable packaging

If you are new to PACK EXPO Las Vegas — or a seasoned attendee — here are tips to help manage your time and schedule at the show, and check packagingstrategies.com for more coverage for daily highlights.

ADVERTISEMENT

Managing the Event

My Show Planner: Use this online tool to create a customized plan at the show.

Mobile App: Use the app for news, events, shuttle times, interactive floor plans and more, happening in real time.

The First-Timer’s Lounge: Your “First-Time Attendee” badge will be your pass to enjoy free refreshments, show planning resources, comfortable seating and charging stations. Located in Room S224, Level 2, South Building. Open during show hours.

All of the resources listed above can be found at packexpolasvegas.com.

PACK EXPO Las Vegas and Healthcare Packaging EXPO present the opportunity to see solutions from other vertical industries to help address production challenges and boost innovation; evaluate new products, technologies and suppliers; and discover what’s trending and find unexpected solutions from other industries. PACK EXPO brings together industry professionals from around the world to catch up on the latest technologies and trends. For more information and to register, visit packexpolasvegas.com or hcpelasvegas.com.

HOT SPOTS THIS YEAR:

PACK TO THE FUTURE

An Interactive Exhibit Exploring the Past, Present and Future of Packaging

Experience into the special association between people and packaging. Located in North Hall (N-11030) here is what you can expect to see in this exciting new exhibit area.

Packaging Past

This exclusive, new exhibit, showcases the evolution of packaging and processing. Explore how packaging developed as civilizations and trade evolved, how the industrial and scientific revolutions led to rapid innovations and mass production and how the digital revolution is shaping the future of packaging.

This curated exhibit includes nearly 30 historic packaging machines dating from the late 1890s to the late 1970s and is surrounded by imagery supplied by CPGs, museums, and others such as Coca-Cola, General Mills, Kellogg, Hormel, Anheuser-Busch and Merck. Don’t miss the one-of-a-kind displays, historic machines, packages, photographs and videos.

Hear how the curators put this museum-quality exhibit together.

Packaging Present

On the show floor, you'll have a first-hand look at how the packaging and processing industry adjusts in present day by seeing evolutions in e-commerce, sustainability, remote access, healthcare packaging and more. Check out the extensive lineup of exhibitors and the products and technology they plan on showcasing through the show planner directory.

Packaging Future

The PACK to the Future Stage, featuring free presentations by industry experts, will showcase advancements such as sustainable solutions, smart packaging and artificial intelligence.

EXHIBITOR INNOVATIONS

Some of the innovations attendees will discover on the show floor are below. Save the booth numbers on your My Show Planner tool.

Markem-Imaje to Showcase End-To-End Supply Chain Solutions

Markem-Imaje (C-2232) will demonstrate its one provider proposition which spans packaging operations, track-and-trace, serialization, authentication and consumer engagement.

Confirming Markem-Imaje’s participation in PACK EXPO, Mark Boksa, North America sales director, Markem-Imaje saiys, “We understand the challenges our clients face in providing safe and authentic products to their customers. It’s difficult for these manufacturers to protect their customers and their brands when dealing with evolving regulatory requirements and complex global supply chains.”

Boksa adds, “It’s clear that a one provider solution is highly effective in helping companies overcome these obstacles, which is our aim with our end-to-end supply chain solutions.”

Markem-Imaje’s end-to-end supply chain solutions encompass:

Messaging — message design, automation and data management

Marking & coding — primary/secondary coding and pallet labelling

Verification & inspection — packaging accuracy, quality assurance and data integrity

Line control — production control, printer performance and overall equipment effectiveness

Serialization — full-stack L1-L4 including aggregation and pallet labelling automation

Authentication — 100% unique, non-additive and data-enriched digital identity

End-to-end traceability — seamless and secure data exchange ensures end-to-end supply chain tracking

Connected consumer — real-time authentication, trust and credibility and customer feedback

Data intelligence — business insight and supply chain visibility

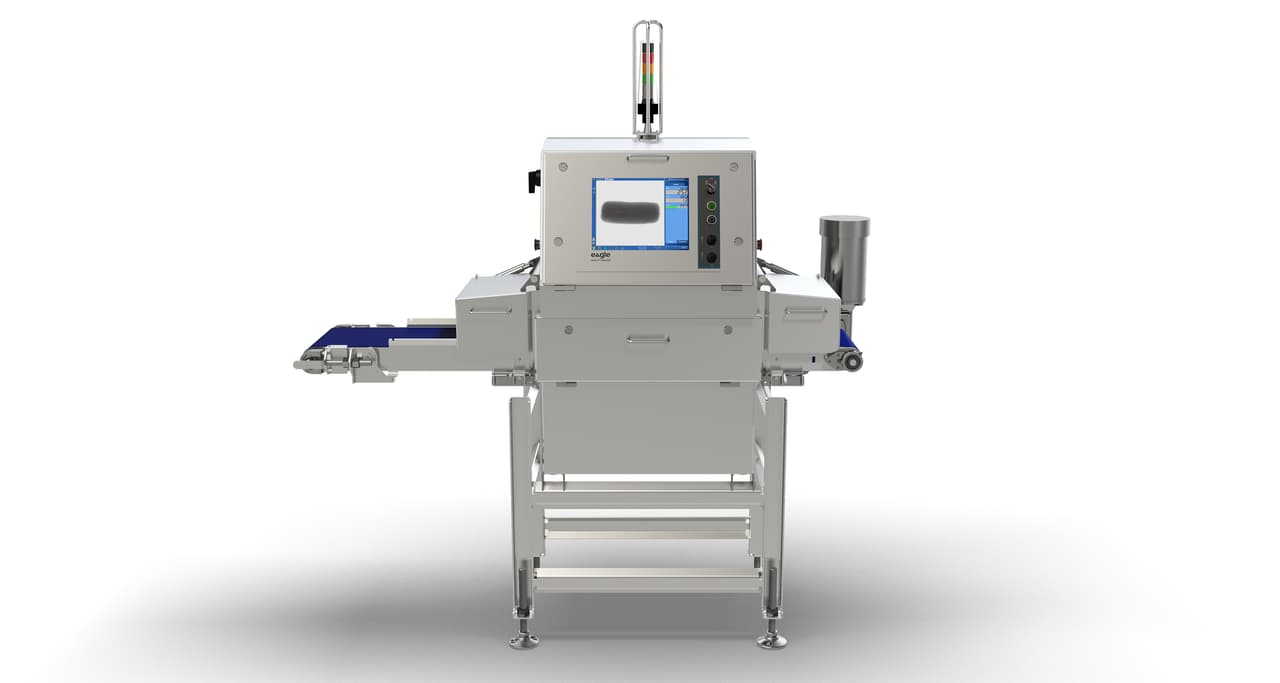

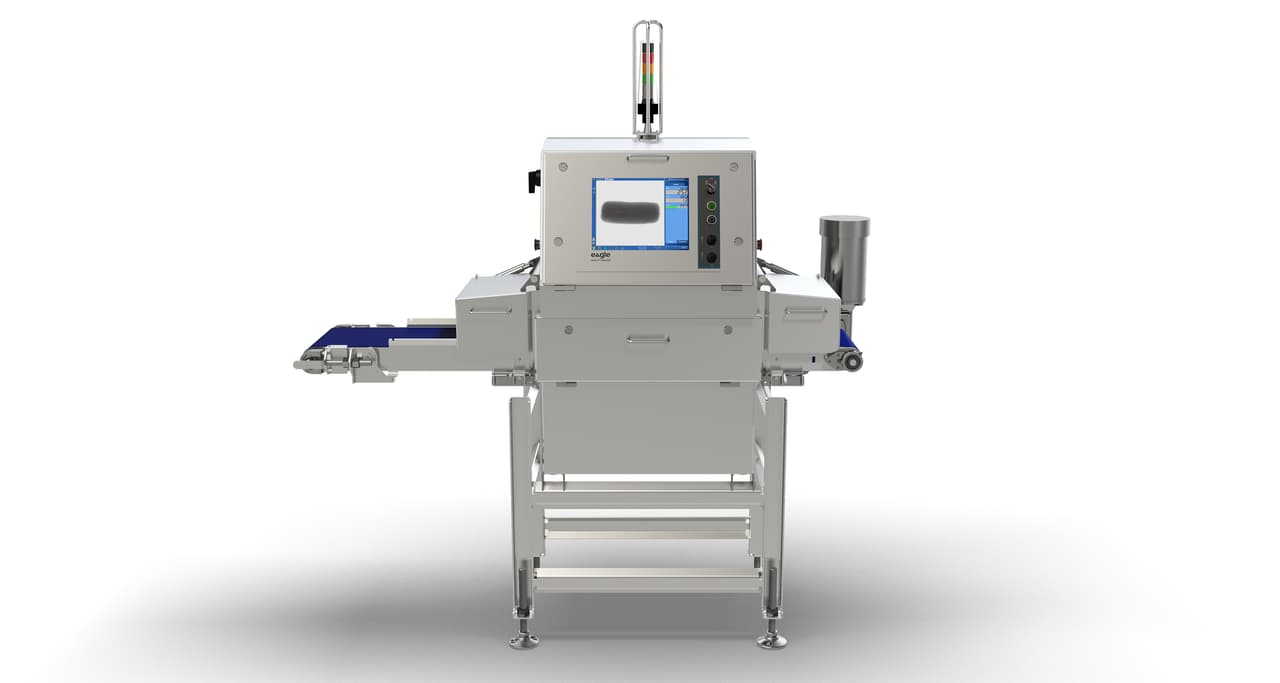

Eagle Pack 240 HC

Eagle Product Inspection to Demonstrate Versatile Systems

Eagle Product Inspection (C-1506) will be running two high-performance x-ray systems used for packaged meat, poultry, dairy and other food applications where daily sanitation is required:

Eagle Pack 240 HC will be set up for a chub package configuration at PACK EXPO. In addition to ground beef, other processed meats like salami and bologna can be run through this machine, which conducts important checks for both safety and quality. Among other functions, the Pack 240 HC inspects product dimensions and ensures the correct count and placement of metal clips.

Eagle Pack 400 HC, with a 400 mm belt, is designed to run a variety of fresh meat and dairy products, including larger packages of meats and cheeses and multiple containers of yogurt, sour cream or ricotta cheese. Like the Pack 240 HC, the Pack 400 HC features a sanitary design for easy washdown and no buildup of debris.

Both the Eagle Pack 240 HC and Pack 400 HC are equipped with Eagle’s PXT detector technology. First introduced in 2020 for superior bone detection in poultry and now available for other food applications, PXT has proven effective in finding bones in seafood and in items such as prepared meals packaged in bowls.

In addition to seeing these systems in operation at Eagle's booth, PACK EXPO attendees can bring product samples with them to test on the machines while there. “It’s a great opportunity for live test runs,” says Ken Falk, regional sales manager for Eagle Product Inspection.

According to Falk, the pandemic spurred a variety of product line additions and updates and highlighted the importance of versatile automated systems. “In COVID-19 times, a lot of our customers went through changes, frequently switching from larger commercial packaging to smaller consumer-sized packaging, as restaurant and hotels were closed and demand for smaller products increased. Advanced-x-ray systems gave them the ability to inspect new and different products in a seamless way,” he says. In addition, more co-packers began using x-ray inspection as a safety and quality verification tool as their businesses grew during the pandemic.

“Looking ahead, even as some trends are shifting again, we still see a strong need for flexibility. Eagle's x-ray machines, including the Pack 240 HC and Eagle Pack 400 HC and others, help users easily switch from one product to another,” Falk says. “Agility will continue to be a priority.”

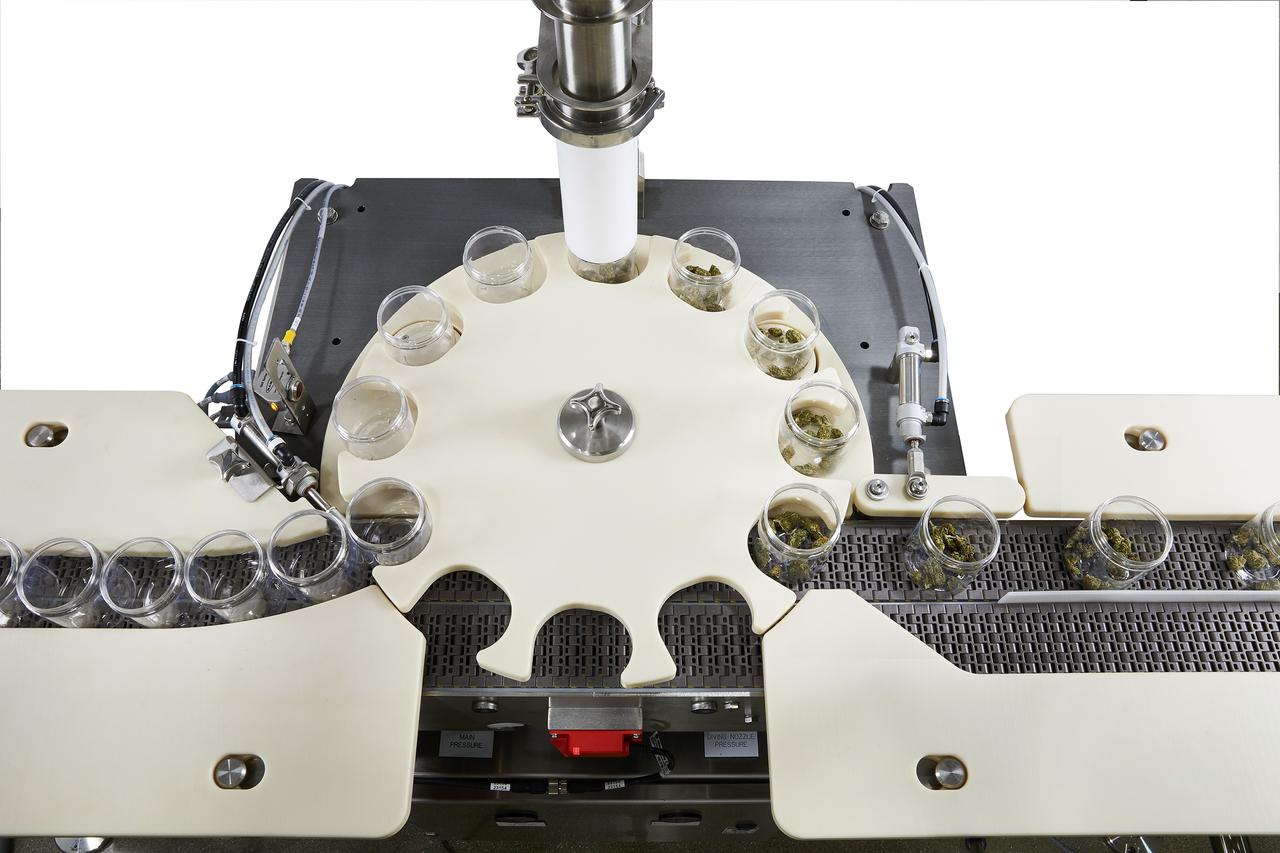

Spee-Dee Packaging Machinery (C-2607) cannabis jar filling system

Spee-Dee to Show High-Speed Cannabis Filling System

Spee-Dee Packaging Machinery (C-2607) cannabis jar filling system automates jar packaging and filling of cannabis. A primary challenge with packaging cannabis is the weight variance of the empty jar is often greater than the total weight of the product being packaged. The unique tare gross weighing system eliminates any inconsistencies by weighing the empty jar and then subtracting the weight of the empty jar from the gross weight of the filled jar to determine the actual net weight of product in each jar.

The system’s accuracy of 0.01 grams reduces costly product loss for fill sizes from 3.5 to 7 g. Vibratory settling helps product flow into containers. The system rejects under and overweights. Integrated with a multi-head weigher, the system provides the fastest, most accurate fills of flower or ground cannabis on the market.

In addition, Spee-Dee’s cannabis filling system features a simple design that enables thorough cleaning. A sanitary funnel and conveyor system ensures hygienic filling with quick changeover while a stainless steel frame and open base allow for easy cleaning. No-tool star wheels and rails enable quick product changeovers.

Antares Mini manual station

Antares Vision Group to Demo New Mini Manual Aggregation Station for Small- to Mid-Sized Production

Antares Vision Group is showcasing a variety of hardware and software solutions at multiple booths. Booth 6502 in the Healthcare Packaging Expo section, the company will offer live demonstrations of a new standalone module for manual aggregation. Ideal for small- to mid-sized production, the Mini Manual Station maximizes manual aggregation productivity and, among other benefits, efficiently supports post-lot reworking operations in warehouses and distribution centers.

Following the situation-specific recipe — for example, the number of cartons per case — the Mini Manual Station aggregation unit issues the upper level, “parent” container label once the preset quantity of items has been scanned into the system. The unit features an ergonomic design for easy, multi-point access and an always-on handheld scanner for fast, reliable code reading.

Both at its Healthcare Packaging Expo booth and main hall (C-3938), Antares Vision Group will be demonstrating Track My Way. a next-generation track and trace platform providing dialogue between various stakeholders throughout a product’s supply chain journey and lifecycle. The system protects production process and distribution channel transparency while providing increasingly sophisticated consumers with informative, reassuring sourcing information.

Track My Way helps companies with high-value goods in a wide variety of sectors fight product diversion and counterfeiting, which continue to be critical concerns across numerous industries. The system was developed for a landscape where the value of brands depends not only on the benefits of its products but also the assurance of safety and security companies can provide to their customers. The platform allows consumers to review certified information about the product origin, manufacturing process and distribution chain, offering the guarantee of integrity and authenticity.

HEALTH AND SAFETY STANDARDS

Information and guidelines are ever-changing and PMMI is committed to updating its approach based on current government regulations and industry standards. Effective June 1, Las Vegas has returned to pre-pandemic guidelines, however show management will continue to plan with additional health and safety protocols, listed below.

PMMI will implement protocols based on the most up-to-date guidance from the CDC, local and state authorities to help mitigate the risks associated with infectious agents such as the novel coronavirus, which may include:

Increased cleaning in all show management areas

Hand sanitizer stations located throughout the exhibit halls

More dedicated concessions and seating areas

Mailing badges in advance for contact-free registration

Designated first aid area for any immediate needs or medical issues

Face coverings: All show participants should follow CDC and local guidance with regard to face coverings. Face coverings are recommended but are not required* and will be available on site.

*Current local regulations require face coverings for all individuals regardless of vaccination status on public transportation including the show shuttle buses, monorail, taxis and rideshares.

In order of feature article appearance, images by / courtesy of LPETTET / iStock via Getty Images Plus, PMMI, Markem-Imaje, Eagle, Spee-Dee, Antares, and Anna Pismenskova / iStock via Getty Images Plus.