PACK EXPO PROFILES

Ultimate Efficiency Is Achieved with Moisture Control

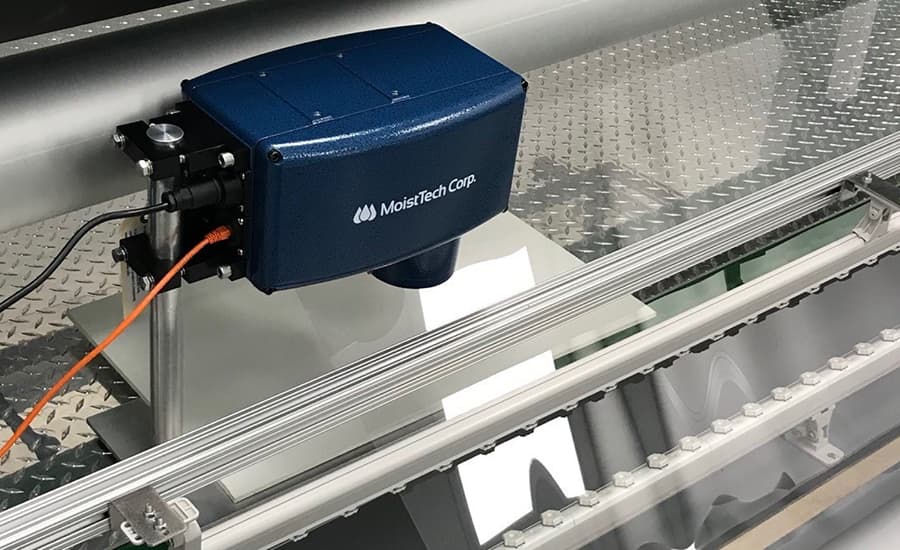

MoistTech is the leader in Moisture Measurement and Control as well as monitoring the Coating Moisture / Thickness for the paper, converting and film applications. Non-contact and insensitive to material variations such as particle size, material height & color, our moisture sensors provide continuous, reliable readings with zero maintenance and a one-time calibration with a non-drift optical design allowing operational personnel to confidently make immediate process adjustments based on real-time measurements.

MoistTech is supported by the original manufacturers of Near-Infrared (NIR) technology in the industrial moisture industry, manufacturing a range of on-line sensors & at-line instruments for moisture measurement and real-time moisture process control. MoistTech has developed the IR 3000 moisture sensor which is ideally suited to measure the moisture levels as well as water and solvent based coatings and coat weight thicknesses during the paper/converting process, improving manufactures product quality and increased productivity with substantial cost savings.

With well over 40 years of moisture analyzer and transmitter experience we understand the savings and potential increase with improved productivity. Therefore, we have an unbeatable promise of customer satisfaction on all our equipment and challenge you to put MoistTech Corp. up against your current method to obtain unsurpassed success!

See immediate benefits:

NIR (near-infrared) technology - highest accuracy

Immediate process line adjustments

Proper dryer control

Reduced waste/wasted product

Low to zero maintenance

Process optimization

Low cost and high accuracy

Improved product quality

Reduced energy

Plant production & efficiency monitoring

One-time calibration & zero drift

Insensitive to material variations

Proper moisture control can:

Minimize waste and product loss

Reduce costs

Increase product quality

Maximize plant efficiency

Promote dryer efficiency

Provide process optimization

Energy savings