Protecting Today’s e-commerce Supply Chain with Advanced Packaging

As e-commerce continues to grow and supply chains evolve and become more complex, the ability to move goods in a safe, compliant and efficient manner has become increasingly important (and difficult). This is especially true when it comes to shipping highly regulated dangerous goods (DG), such as lithium batteries.

By Bill Barger

The use of lithium batteries (which power laptops, cell phones, medical equipment, power tools and more) continues to grow, with the lithium-ion battery market projected to exceed $94 billion by 2025. This growth brings with it stricter rules and harsher noncompliance penalties pertaining to lithium battery shipments, in turn creating new challenges for companies that manufacture and distribute lithium batteries (and the technologies that rely on them).

To maintain a safe and efficient supply chain in the face of these e-commerce challenges, companies should rethink their approach to packaging.

ADVERTISEMENT

Lithium Batteries Shipping Challenges

While there are inherent challenges and risks associated with shipping any dangerous goods, lithium batteries have topped the list in recent years. In fact, lithium batteries pose such a fire danger that strict regulations — from commercial aircraft bans to state-of-charge rules — have been imposed around transporting them. And if a shipment fails to meet hazmat compliance regulations, or if a dangerous battery-related incident halts transportation in its tracks, the cost of lost time, compliance fines and possible negative press can be severe.

While expanding transport regulations are part of an industry-wide push to ensure safety, many organizations have struggled to deal with the impact these restrictions have on the supply chain. This includes finding a safe, compliant and cost-effective way to package lithium batteries and the devices that contain them.

Next-Gen Packaging for High-Risk Shipments

In today’s increasingly challenging shipping landscape, companies that manufacture and distribute lithium batteries should look for opportunities to use new and innovative shipping solutions that can streamline the shipping process, improve regulatory compliance and reduce risk.

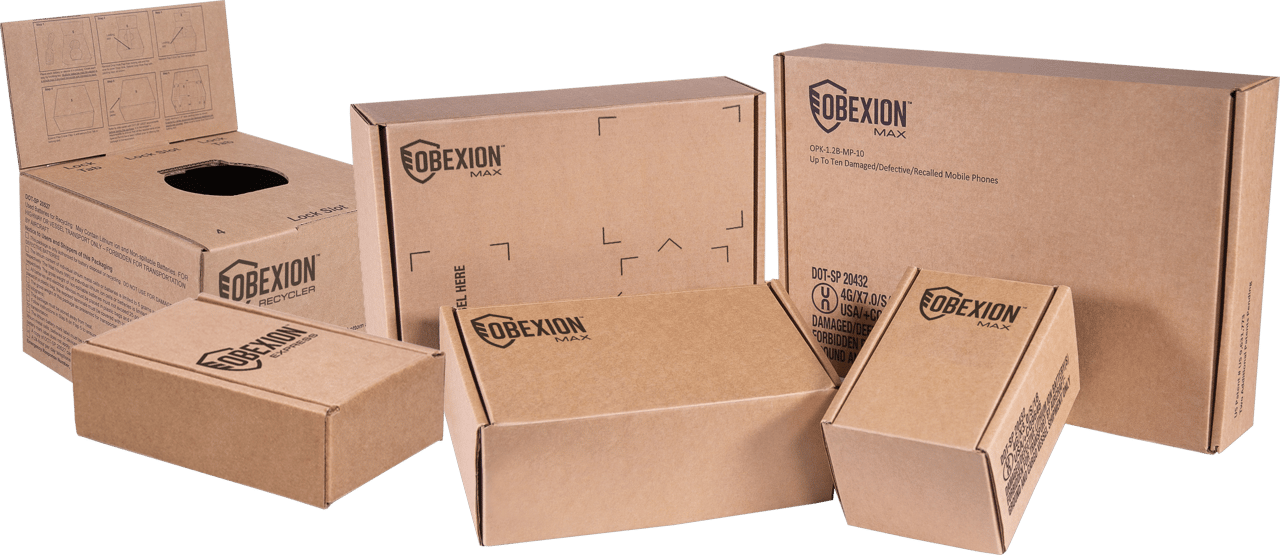

One key strategy is to embrace next-generation packaging engineered specifically for transporting lithium batteries. These modern packaging solutions provide a thermal barrier that mitigates the risk of fires by containing pressure, fire, gasses and projectiles, yet requires no use of gel packs, heavy liners or fillers. This makes the transport of lithium-related items safer, easier and more cost-effective.

These advanced packaging solutions streamline and improve safety both when sending lithium batteries and related devices to customers, and during the returns management process.

The Reverse Logistics Surge: Protecting Return Shipments

Today’s e-commerce environment has led to an increase in reverse logistics activity — with consumers returning to stores and stores returning to manufacturers and distributors more often than in the past. In fact, 1 in 4 e-commerce purchases are returned — and for electronics, that number is 48%.

Return shipments must comply with the same hazmat rules as shipping items to customers. Since it’s the shipper’s responsibility to comply with hazmat transportation regulations, customers must be equipped to adhere to these rules whether they’re aware of them or not.

Next-generation boxes that arrive preassembled and pre-labeled with simple closure instructions help expedite returns management, which can directly impact customer satisfaction while mitigating risk and enhancing the ability to maintain regulatory compliance. Not only does this simplify the returns process to improve the customer experience, it can also provide additional benefits:

Competitive Differentiation: Ease of doing business and excellent customer service can help your company stand out to consumers, suppliers and other supply chain partners.

Risk Mitigation: Comprehensive returns management helps mitigate the risk that comes with shipping lithium batteries and reduces the chance of injuries, fines and environmental incidents.

Product Recall Preparedness: Businesses can avoid compounding issues and reduce the potential for a return-shipping incident while a recalled product is en route back to the manufacturer, especially if transporting damaged or defective lithium batteries.

Better Packaging Enables a Better e-Commerce Supply Chain

As the number of lithium batteries being shipped continues to rise, more organizations will be forced to navigate today’s complex DG shipping landscape.

Companies that manufacture and distribute these items must have adequate processes and solutions in place to ensure compliance with complex, ever-changing regulations, and to maintain safe and smooth operations. By evolving their approach to boxes and shipping, companies can leverage next-generation packaging that promotes safety and efficiency for anyone handling lithium batteries (or other dangerous goods) — whether those goods are being sent to the customer or returned by the customer.

Bill Barger is an expert in hazmat/dangerous goods (DG) packaging with 30 years of industry experience. As senior packaging product manager, Barger leads Labelmaster’s Packaging Product Line. His industry association involvement includes the American Biological Safety Association, Council on Safe Transportation of Hazardous Articles (COSTHA) and the Dangerous Goods Advisory Council.

Courtesy of Labelmaster

MechanismDigital / Creatas Video+ via Getty Images Plus