THE PERFECT PARTNERSHIP:

Profitability and Sustainability Go Hand-in-Hand for Package Printing

Far from increasing operating costs, sustainability is often the key to saving money and increasing profitability.

BY DOUG SHARDT

As the effects of climate change become more pronounced, consumers demand action from their favorite brands in food, cosmetics, pharmaceuticals and other industries that provide daily necessities. To meet consumer expectations, package printing companies are adopting green practices, but the myth persists that going green comes at the expense of profit. The reality is that decarbonization and profitability can coexist and become key differentiators.

Decarbonization in the printing industry is nothing new. The push for sustainability started decades ago when printers began eliminating volatile organic compound (VOC) emissions and replacing alcohol-based cleaning solvents with environmentally friendly alternatives. Regulatory pressure has also been a long-time driver for adopting greener printing practices, but the pressure has ramped up in recent years.

Despite persistent calls to decarbonize, concern over the cost of implementing sustainability initiatives has slowed the adoption of green practices in the printing industry. However, recent studies on the correlation between labor productivity, return on assets and carbon productivity (i.e. decarbonization) show that it’s possible to increase profits while reducing carbon emissions. The key to achieving these seemingly contradictory objectives is to increase productivity while eliminating waste.

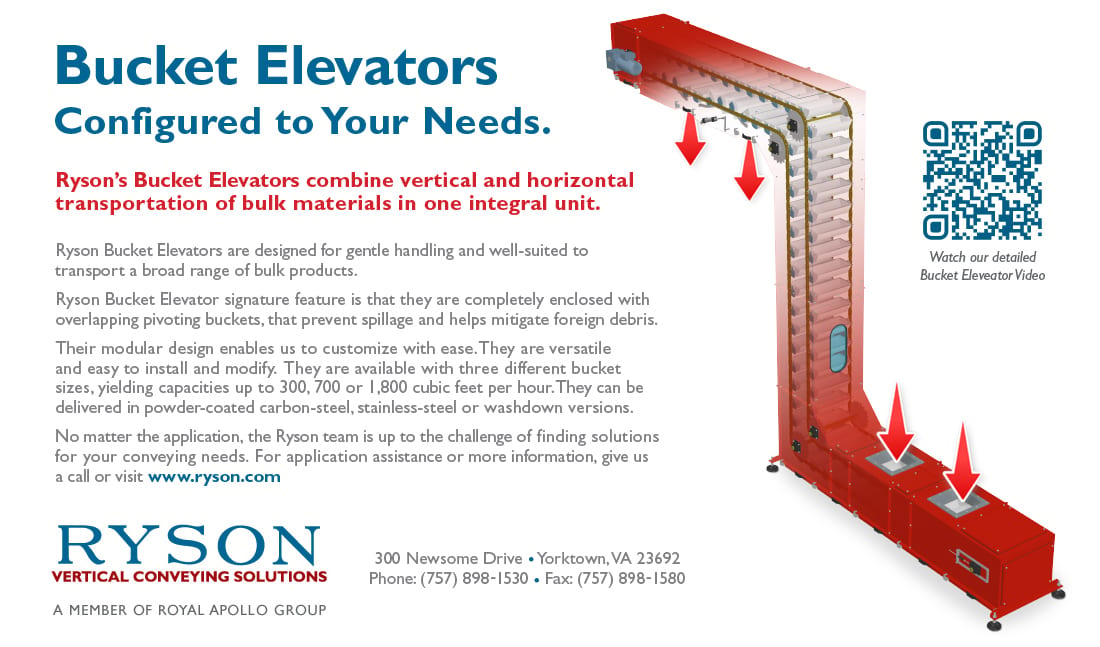

ADVERTISEMENT

Although concerns about costs remain, resisting calls to implement sustainable printing methods is no longer an option. To comply with regulatory mandates and consumer demand, CPGs are placing increased pressure on package printing companies to support their sustainability initiatives. Cost-conscious printers can leverage digital transformation and advances in printing press technology to minimize makeready costs, reduce wasted resources and energy consumption, and transform their supply chains while meeting the needs of CPGs and other stakeholders.

Leverage Advances in Printer Technology to Improve Productivity

Demand for small-volume printing and quicker delivery is driving advances in printing technology. For example, improvements to the high-speed stability of the feeder, delivery and dampening systems in leading edge printing presses have enabled stable, high-speed printing. Updates to operating systems and a significant reduction in operator touchpoints have also contributed to greater efficiency. At the same time, automatic job presetting in newer presses has dramatically reduced makeready time.

Advances in technology are also allowing printers to replace older, low productivity presses with high productivity equipment that enables the ability to consolidate and downsize the number of presses used by 30% or more. In turn, decreasing the number of presses on the production line reduces paper waste and energy consumption, resulting in higher profits and a major reduction in CO2 emissions.

Examples printed on the Komori Lithrone 6-color 40” offset press (GLX640). The “G” in Komori’s GLX640 advance series offset printing press stands for “green.” These presses are designed to reduce the CO2 footprint of the printing process with reduced energy consumption, low waste and reduced consumables use.

Use Digital Transformation to Turn Printing Plants into Smart Factories

Managing operations at a printing plant involves a lot of variables that make coordinating analog processes and responding to changing conditions difficult. In turn, these challenges can limit the ability to raise overall productivity. Rather than trying to improve individual procedures, operators should focus on optimizing the entire printing process through digital transformation (DX).

By turning a printing plant into a smart factory, fragmented operations can be connected into an integrated, end-to-end production using digital technology. Equipment built on an open platform concept is a good place to start. This innovation allows printing companies to integrate with the systems of other manufacturers and vendors, making it possible to combine and connect new and existing devices to visualize and optimize the entire print run.

With this improved connectivity, real-time information on operations can be obtained to identify problems and take immediate action to resolve bottlenecks. In turn, the ability to respond quickly to issues prevents losses in productivity while increasing profitability.

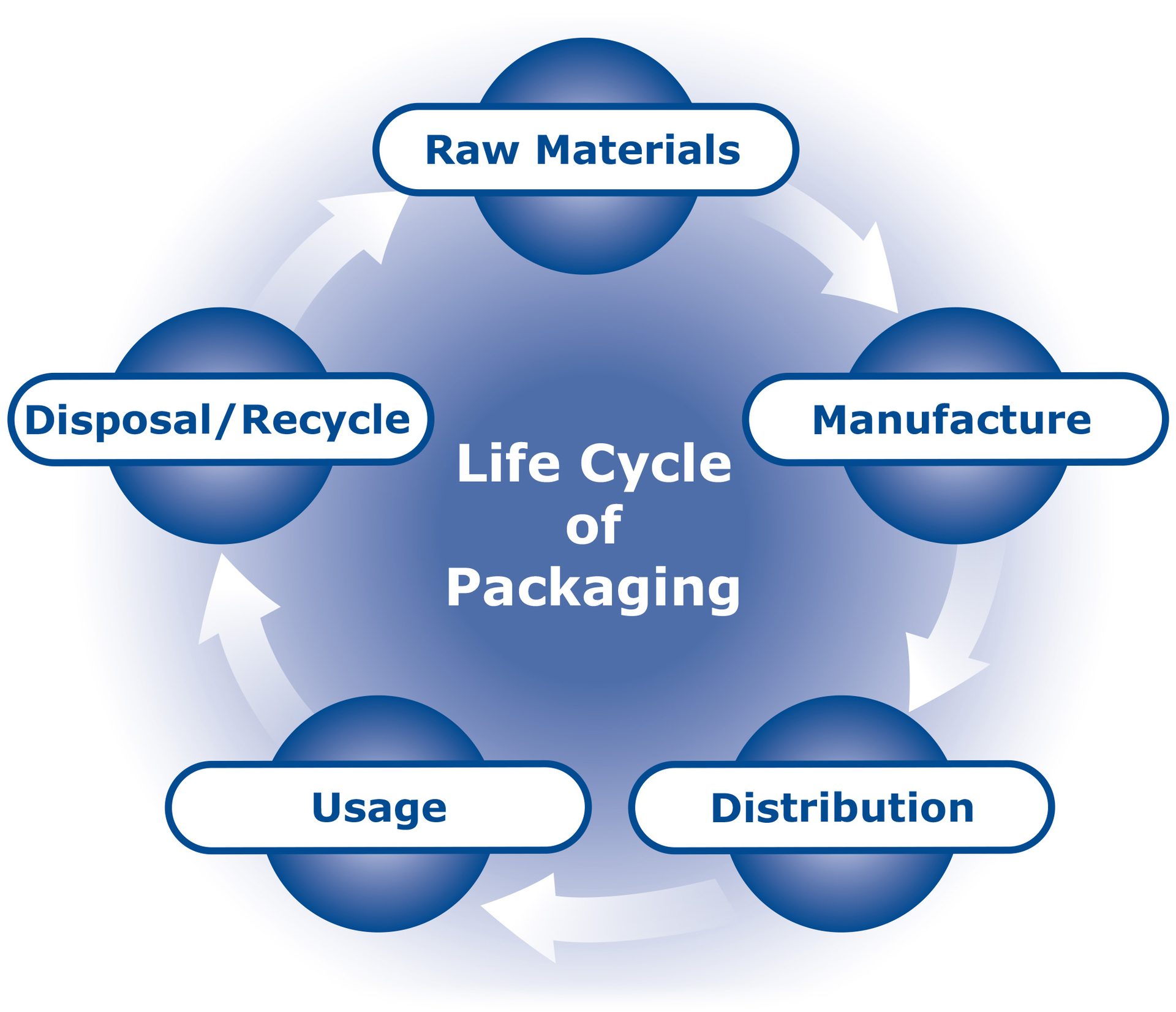

Optimally, businesses should evaluate everything from the energy expended to extract and produce the packaging materials to the downstream implications for the environment of incorporating those materials in the packaging, including the implications for optimizing package design, shipping, storage, recycling, reuse and ultimately disposal — the entire lifecycle.

Transforming the Supply Chain to Minimize Costs and Enhance Profitability

Supply chain issues have been making headlines lately, as COVID-19 continues to impact manufacturing and transportation. In the printing industry, adopting a production process that is profitable for small-quantity print runs can resolve many of these supply chain issues. A case in point involves the use of special colors. High makeready costs associated with color changeovers and roller cleaning force many manufacturers to produce in large lots to stay within budget. As a result, many CPGs must stock inventory for six months or more, even if they only deliver products once a month.

The problem also limits flexibility in the printing process. A simple design change can force manufacturers to scrap inventory already in stock, leading to wasted materials and labor. The resulting loss of inventory can also drive up production costs and cut into profits. However, producing small lots and delivering on a just-in-time basis eliminates the need to stock surplus inventory, drastically reducing inventory risk and makeready costs in the process.

Improving the printing process through advances in technology and digital transformation can have a ripple effect that goes beyond increased efficiency. By reducing energy consumption and wasted paper, ink and other materials, CO2 emissions are reduced, aiding in decarbonization efforts worldwide. Far from increasing operating costs, sustainability is often the key to saving money and increasing profitability.

Doug Schardt is director of Product Management for Komori America, a premier manufacturer of offset and digital printing presses. Schardt’s experience with a wide variety of print applications and his constant involvement in the industry’s newest technologies supports Komori’s dedication to helping its customers navigate the changing market landscape. Visit komori-america.us.