LASER-FOCUSED

ON INNOVATION

From marking cannabis edibles with lasers to eliminating the use of primer in package printing, these companies are at the forefront of coding, marking and printing.

By Brad Addington

Developments in the area of coding, marking and printing recently have been receiving a lot of ink, so to speak, at Packaging Strategies – and deservedly so!

In this article, we focus on game-changing innovations in this area on the part of Sun Chemical, Squid Ink Manufacturing and Videojet.

Achieving Sustainability in the Narrow Web, Tag & Label Market

Packaging Strategies recently talked to Sun Chemical’s Dennis Sweet about how the company has prioritized sustainability in its ink formulations.

Sweet (Vice President of Narrow Web, Tag and Label) notes that Sun Chemical in 2022 spent more than $100 million on research and development, “more than the rest of the industry combined.”

“Most of that is going into research that’s related to or directly involved in sustainability because that’s where the industry’s going. That’s where the brands are going. That’s where our customers are going,” Sweet said.

When it comes to developing sustainable package printing, Sun Chemical follows the five R’s — reuse, reduce, renew, recycle and redesign.

ADVERTISEMENT

“If you think about it, all of the products that we develop fall into one of those five areas,” Sweet said.

One example of “reduce” is a Sun Chemical technology that eliminates the use of primer.

“Most of the industry has developed an approach where they use a primer so that they can apply this primer, and they can use the ink, and the primer will enable that product to function, whether they want it to function as a wash-off or not,” Sweet said. “Sun Chemical has taken a whole different approach, again, with the idea of ‘reduce.’ Why do we have to use a primer? Our technology does not require the use of a primer. It’s a primer-less technology, and it allows either wash-off or retentive applications.”

Check out this exclusive podcast interview here to learn more about Sun Chemical’s solutions and capital investments that are enabling its customers to improve their carbon footprint while standing out on the shelf.

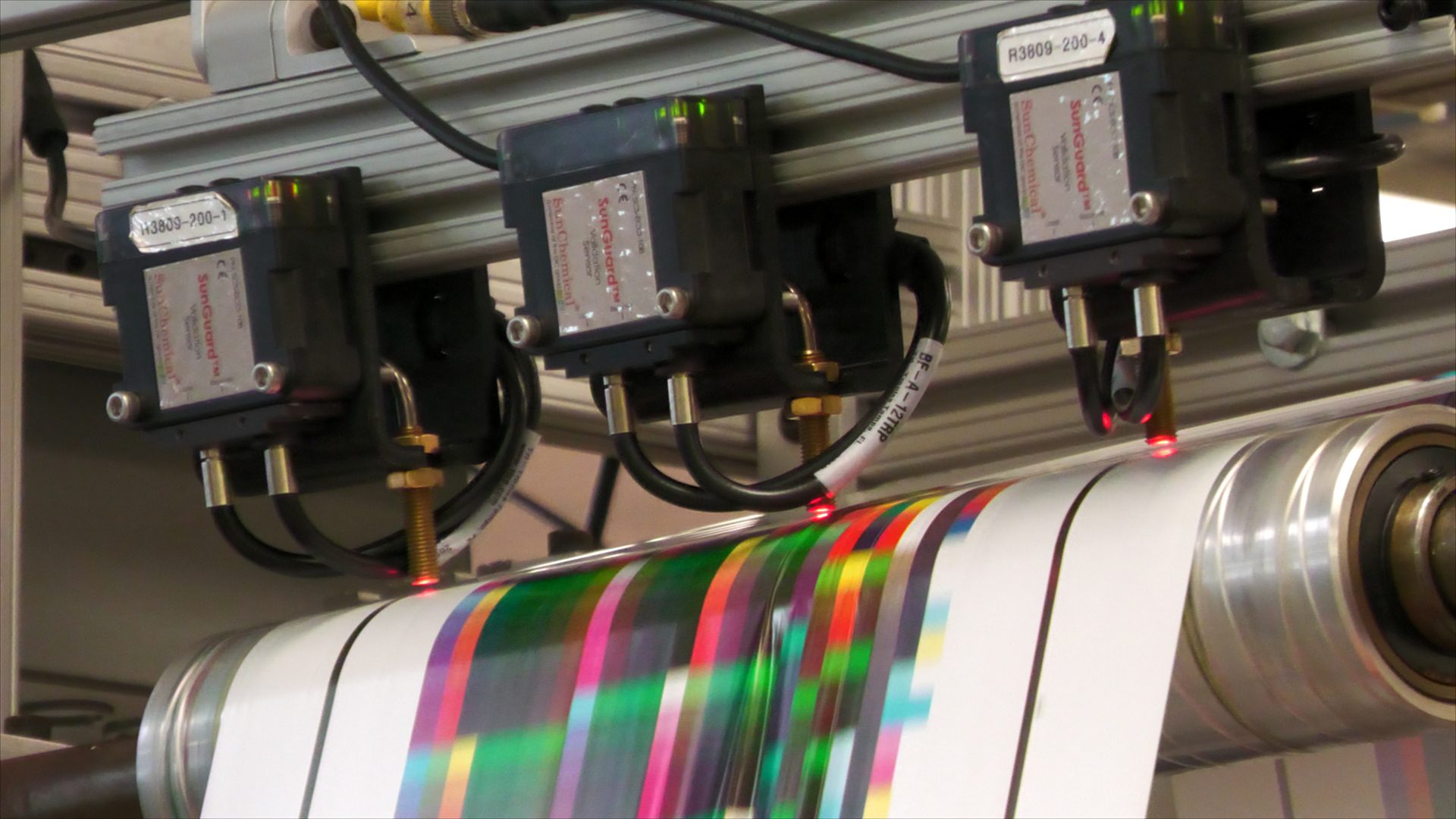

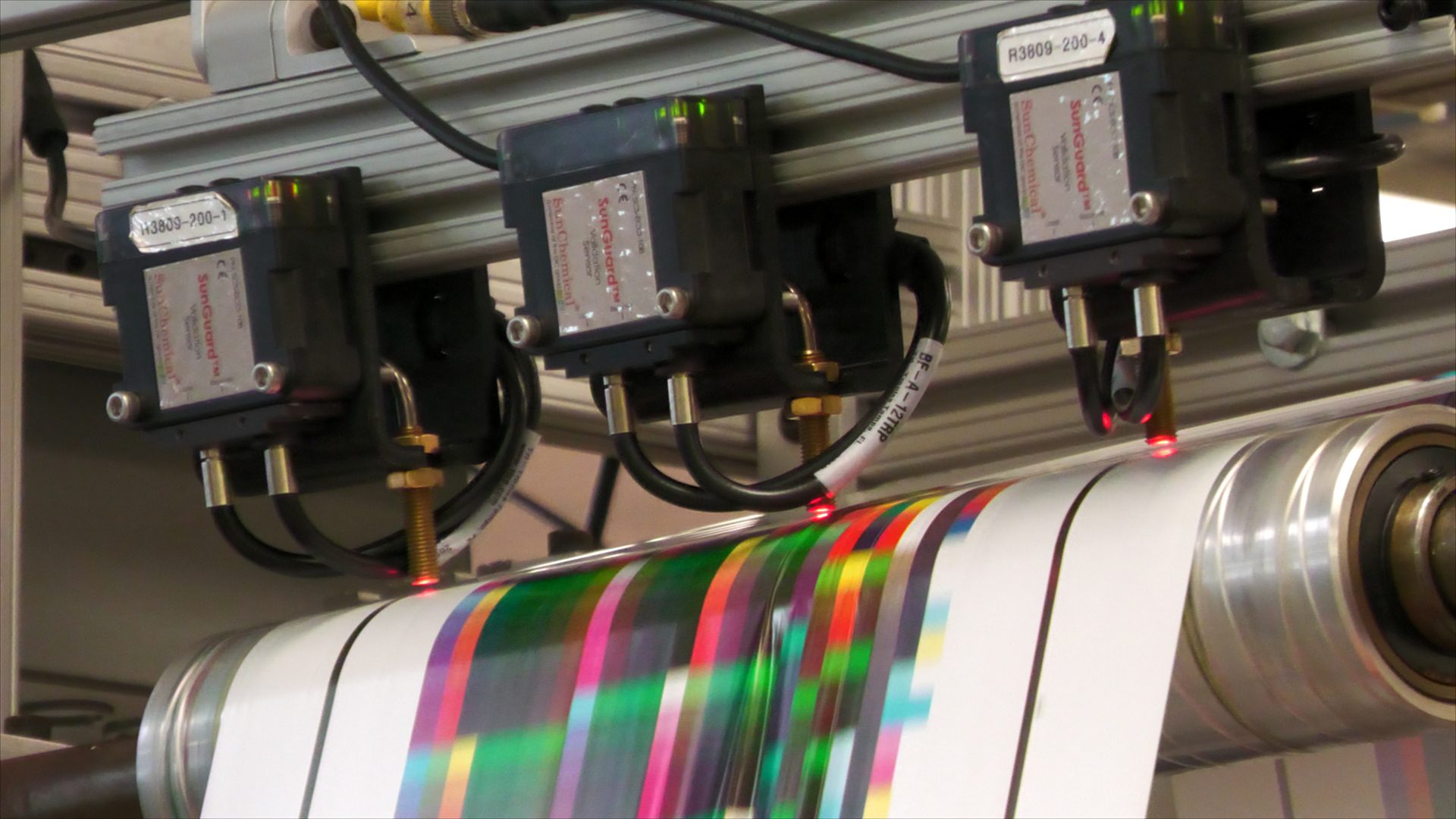

Sun Chemical recently introduced SunScreen, an innovative new system designed specifically for real-time monitoring of coatings during the printing operation which both ensures required packaging performance and delivers a variety of sustainability credentials.

Squid Ink Introduces New Label Replacement Option for Non-Porous Products

Squid Ink Manufacturing, Inc., a leading manufacturer of coding and marking systems for product identification and traceability, introduces the CoPilot® Gemini printing system now with solvent and UV curing capability to print on non-porous surfaces. With up to 5.6” of print height per printhead, the CoPilot Gemini offers a versatile yet cost-effective solution for a variety of product coding and marking applications.

Initially released in October 2022 with oil-based ink capability, the CoPilot Gemini now has the capability to run solvent-based inks, allowing users the ability to print on coated corrugate, polystyrene, films, and a number of other non-porous surfaces. Solvent-based capability is ideal for users looking to replace labels and print directly on glossy cartons, cases, trays, films, or other non-porous substrates.

For applications that require immediate dry times on non-porous surfaces, the CoPilot Gemini can also run UV LED curable inks. UV ink dries only when it comes in contact with a UV LED light source, offering a low-maintenance yet immediate drying alternative for printing on non-porous surfaces. With up to 5.6” of print height and print speeds up to 220 ft/min, the CoPilot Gemini provides a cost-effective solution for making a mark on a wide variety of products and substrates.

The CoPilot® Gemini printing system now has the capability to run solvent-based inks, allowing users the ability to print on coated corrugate, polystyrene, films, and a number of other non-porous surfaces.

The CoPilot Gemini printing system is available now through Squid Ink’s worldwide network of authorized distributors. Sales inquiries should be directed to Joshua Nelson, Squid Ink Manufacturing, Inc., 7041 Boone Ave. N., Brooklyn Park, MN 55428. 1-800-877-5658.

Squid Ink, Eastey, and American Film & Machinery (AFM) are all divisions of Engage Technologies Corporation. Squid Ink manufactures coding and marking systems for product identification and traceability, providing superior-quality inks and low-maintenance printing equipment. Eastey (eastey.com) is a leading manufacturer of heavy-duty shrink-packaging equipment and automated case sealing systems for packaging applications. American Film & Machinery (afmsleeves.com) supplies shrink labelers and tunnels, shrink sleeves, and tamper-evident bands.

Engage Technologies Corporation is headquartered in Brooklyn Park, Minn., with facilities in: Big Lake, Minn.; Spring Lake Park, Minn.; The Hague, Netherlands; and Shanghai, China. The company continues to expand sales and services, with authorized distributors strategically located throughout the U.S. and the rest of the world.

Videojet fiber laser marking systems deliver permanent, traceable, and readable codes on robust, high-density plastic and metal.

Coding and Marking for Cannabis Packaging

Packaging Strategies recently caught up with Chirag Sheth, Global Business Unit Manager at Videojet, to discuss coding and marking options for cannabis packaging.

While traditional inkjet-based technologies in many instances can serve cannabis manufacturers perfectly well, several other options are available.

“We also have laser technology, which is beneficial if you’re trying to mark directly onto an edible,” Chirag notes. “In the state of Colorado, for example, the edible — if it contains THC — needs to contain that diamond warning on it. While we have certain food-grade inks that can be used to print directly onto the edible, a lot of our customers actually use lasers to mark onto the edible. That’s a good option for the cannabis customers that need that kind of technology.”

Listen to the Packaging Perspectives podcast with Chirag Sheth here.