BEYOND BEVERAGE PACKAGING

Craft beer and soft drinks are two products that often come to mind in the context of cans and aluminum as packaging materials, but our recent reporting reveals a broader versatility.

By Brad Addington

Headline

Subhead

Byline

AN

T.

By B

Upon hearing the words “cans” and “aluminum,” it’s logical to think of aluminum cans for beverage packaging.

While aluminum cans for beverage packaging represent an important industry segment, they surprisingly do not enter into this month’s focus on cans, steel and aluminum. It turns out that cans and aluminum play a variety of packaging roles.

In the first of our three focuses, Tom Gordon of Crown Holdings looks at the lifecycle of the food can and how it impacts brand owners, consumers and our overall society.

In the second focus, Steel for Packaging Europe expounds on the group’s recent name and logo changes and also celebrates a new record recycling rate for steel packaging within the European Union.

Finally, we look at how Amcor Capsules — a market leader in the design and manufacture of capsules, closures, and eco-responsible foils for still wines, sparkling wines, and spirits — is preparing to launch a plastic-free foil made of aluminum and paper.

Check out these three equally compelling cases for the use of cans, steel and aluminum.

Caption

Courtesy of xxx

Left: XXX

Courtesy of xxx

Right: XXX

Courtesy of xxx

Text

Caption.

Courtesy of xxx

caption.

Courtesy of xxx

xx

From Harvest to Shelf: Enhancing Quality Through the Food Can

By Tom Gordon, President, Food Packaging North America at Crown Holdings, Inc.

The height of farming season in the United States is in full swing, with crops planted in the spring, tended throughout the summer, and harvested in early fall. Once harvesting time comes around, consumers tend to think about the fresh produce that makes its way from farms to our grocery stores, stands at our local farmers markets, and eventually to our tables. But, what about the canned food that lines store’s center aisles and provides us with produce year-round?

For generations, steel food cans have been a sustainable vessel for storing, protecting and delivering nutritious food to consumers across the U.S. throughout the year. With a more recent societal push for prioritizing fresh produce, it can be easy to overlook canned goods and the intricate process that works to capture and package crops at their peak freshness to be enjoyed all year. Additionally, the sustainable attributes of steel cans are aiming to combat the food waste epidemic in our country and provide a format that can be easily recycled, promoting a circular economy.

Let’s take a look at a food can’s lifecycle and how it impacts brand owners, consumers and our overall society.

Tom Gordon

READ MORE

Enhancing Nutrition

Each year in the U.S., crops are planted methodically with fresh consumption and canning in mind. To ensure produce is packed at its peak freshness, crops are picked at a precise time and sent to canning facilities often located within miles of the farm to ensure they are packaged within hours of harvest. Since produce can begin to lose nutrients as soon as harvested, the efficient canning process locks in those nutrients for ultimate benefits.

At canning facilities, produce is promptly cleaned, prepared, packed and sealed into cans, and heated to a temperature that destroys microorganisms and spores that can cause foodborne illness, preparing the food for the duration of its shelf life. A tight seal and strong can barrier properties protect the contents from any exposure to light, air and humidity, leading to canned food’s ability to be safely transported throughout the supply chain, eventually presenting consumers with fresh, nutritious products throughout the year.

McCall Farms: A Legacy of Quality

Crown works hand-in-hand with its food producer customers to understand their missions, challenges, and priorities, finding ways to elevate their products through steel food cans. Family-owned McCall Farms has built an entire legacy around its reliable fruit and vegetable brands. The company knows that maintaining its loyal customer base requires careful attention on the complete farm-to-consumer journey, utilizing the right tactics to preserve product flavor, texture and nutritional value along the way.

Since its origins, McCall Farms has chosen the steel can to help protect those high standards for product quality. Recognizing that the canning process locks in freshness and richness in record time after the point of harvest, the producer leverages steel to maintain peak freshness long-term. With strong barrier properties to damaging oxygen and light, as well as durability and tamper-evidence, the food can enables McCall Farms to distribute a safe, tasty, consistent product. It also helps them to meet ongoing missions to provide locally, thoughtfully grown goods to U.S. consumers and to combat food waste where possible. McCall Farms has made strategic choices that uphold their commitments as a producer of essential consumer goods, establishing a deep level of trust with its customer base — much of which can be attributed to a high-quality, safe product that always delivers.

Tackling the Food Waste Challenge

Beyond the nutritional benefits of canned produce, food cans are playing a critical role in combating our nation’s food waste epidemic. According to Feeding America, $473 billion worth of food is wasted annually in the United States, with 38 percent of all food going unsold or uneaten. We all know the struggle of buying fresh produce that spoils quicker than expected or gets buried in the refrigerator (out of sight, out of mind.) With canned food, consumers can rely on these products as a safe, nutritious and longer-term food source that might be a better fit for stocking up or using in certain recipes.

Food waste can also occur at earlier stages of the value chain due to overproduction on farms or product damage during transport. While farmers regularly plan against demand and what purposes crops will be harvested for, seasonal gluts are not uncommon and can ultimately result in food waste. If excess crops harvested by farmers were to be sent for canning, it would make a significant difference in reducing crops that are discarded due to differences in forecasted vs. actual demand.

Maximizing Sustainability

Once a steel food can makes its way into a consumer’s hands, the sustainability attributes of the can present ways for consumers to participate in and strengthen the circular economy. Steel food cans are infinitely recyclable, meaning they can be recycled into the same material over and over again without loss of original attributes. Compared to other packaging formats that may share mixed messages on recycling, consumers can trust the recyclability of food cans and know they have a proper way to dispose of the material for eventual reuse.

Utilizing a Trusted Format

Canned food is not new, and perceptions have changed over time since our ancestors introduced the format dozens of decades ago. At a time when food waste is high and sustainability is top of mind more than ever, it is crucial for manufacturers and consumers to be able to rely on a packaging format that delivers nutritious and safe food at all times of year. There are no doubts steel food cans will remain a chosen format for generations to come, and it is up to manufacturers to remind consumers of the benefits and importance of this trusted format.

McCall Farms brand Margaret Holmes has grown since the 1930s to include a wide variety of Southern-style fruits and vegetables, all canned in Effingham, South Carolina, and sold nationwide.

Courtesy of Crown Holdings, Inc.

COLLAPSE ARTICLE ABOVE

APEAL Changes Name to Steel for Packaging Europe, Adopts New Logo

Steel for Packaging Europe has announced its transformation from APEAL (The Association of European Producers of Steel for Packaging), marking a significant milestone in the organization's journey.

Accompanying this change is a dynamic name and a fresh logo, capturing the essence of steel's circularity and its inherent multiple recyclability within a closed material loop.

Founded in 1986, Steel for Packaging Europe represents the five major European producers of packaging steel: Acciaierie d’Italia A.S., ArcelorMittal, Tata Steel, thyssenkrupp Rasselstein and U.S. Steel Košice.

Steve Claus, secretary general of Steel for Packaging Europe said, “After extensive consultation with our stakeholders, we have adopted our new name and logo to help us better reflect steel’s inherent material capabilities to be produced, reproduced, born and reborn, forever.

“Offering a strong and versatile solution for the secure packaging of food and other goods, steel packaging plays a vital role in preserving products without need for refrigeration, extending shelf life for up to five years and reducing waste. These properties make it the model material for a circular economy.”

READ MORE

Claus added: “With 78.5% of steel packaging recycled in 2021, steel remains the most widely recycled sales packaging material in Europe, a testament to its unique properties and the collaborative efforts of stakeholders across the value chain to maintain a closed material loop.”

As part of the rebrand, Steel for Packaging Europe has launched a new website.

The platform serves as a dynamic hub, showcasing the circularity, design flexibility, and versatility of steel packaging. It also highlights recent industry innovations, including the Chromium-free Passivation Alternative, and provides insights into the industry’s position on a range of policy and environmental issues, as well as the collective EU steel industry’s bold vision to achieve a carbon-neutral future by 2050.

Record Recycling Rate

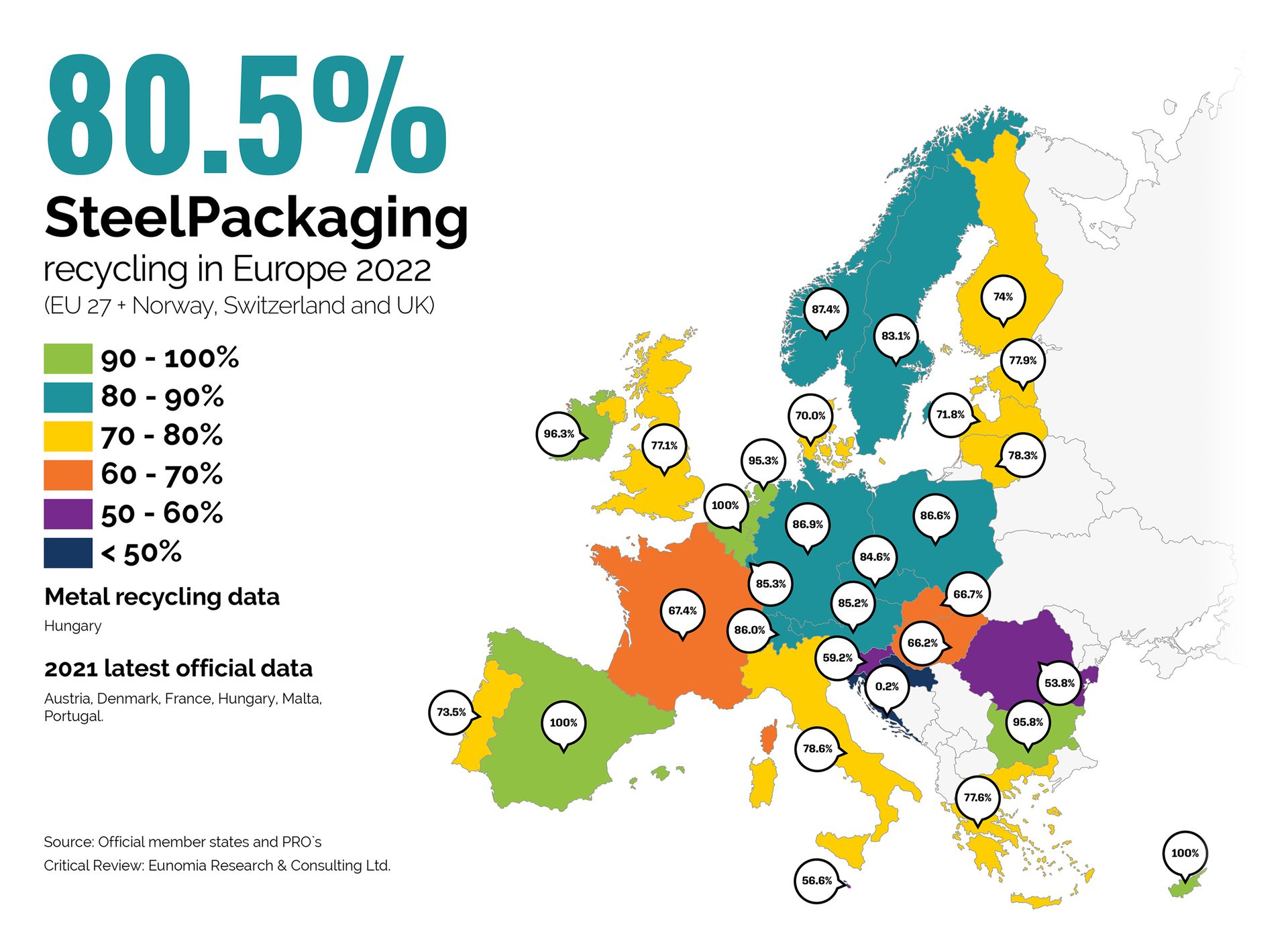

Steel for Packaging Europe has confirmed a new record recycling rate for steel packaging, following the harmonized method for calculating packaging recycling rates within the EU.

Independently verified figures published by Steel for Packaging Europe confirm that 80.5% of steel packaging placed on the market was ‘really recycled’ in 2022. It follows the announcement in December 2023 that steel packaging had met its EU recycling rate target for 2025, four years ahead of schedule.

The 2022 recycling rate also represents a 2% increase versus the 2021 recycling rate and confirms steel packaging remains the most widely recycled sales packaging material in Europe, which is testament to its unique properties and the collaborative efforts of stakeholders across the value chain toward reaching a 100% closed material loop.

“I am proud that the newly published figures correspond to the amount of packaging that is actually recycled at the entrance of recycling operations and not merely the packaging which is collected,” said Steve Claus, Secretary General of Steel for Packaging Europe. “This harmonized method for calculating packaging recycling rates creates a level playing field for all packaging materials in Europe.”

Claus notes that, previously, EU member states used varying methods to determine recycling rates for different materials, leading to inflated rates and obscuring the recycling challenges associated with some packaging formats.

The announcement comes in the wake of the formal adoption of the Packaging & Packaging Waste Regulation (PPWR) voted by the European Parliament (EP), which includes a range of stricter recyclability measures.

Claus said he is particularly pleased that the new PPWR includes the establishment of design for recycling criteria – applicable to all packaging – and the introduction of a performance grading system with clear criteria.

“The three grades of defined recyclability percentages — A, B, C (95%/80%/70%) to comply with by 2030 and two — A, B (95%/80%) by 2038, will ultimately drive any material that is less than 80% recyclable from the market,” Claus notes. “Steel packaging, with all formats graded A or B, demonstrates a superior performance compared to other materials such as plastics and laminated cartons.”

Steel for Packaging Europe has confirmed a new record recycling rate for steel packaging, following the harmonized method for calculating packaging recycling rates within the EU. Independently verified figures published by Steel for Packaging Europe confirm that 80.5% of steel packaging placed on the market was ‘really recycled’ in 2022.

Courtesy of Steel for Packaging Europe

COLLAPSE ARTICLE ABOVE

Amcor Capsules, Moët & Chandon to Launch Plastic-free Aluminum/Paper Foil

Amcor Capsules — the market leader specializing in the design and manufacture of capsules, closures, and eco-responsible foils for still wines, sparkling wines, and spirits — is preparing to launch ESSENTIELLE, a plastic-free foil made of aluminum and paper, in October 2024.

With more than 280 years of history, Moët & Chandon, owned by LVMH, manages the largest vineyard in Champagne, with nearly 1,300 hectares of vines. The brand intends to continue its movement toward more sustainable packaging and is working with Amcor Capsules on the development and launch of its plastic-free foil.

READ MORE

An Innovative and Eco-Responsible Creation

The ESSENTIELLE foil is created using paper made in Europe, a material that has a lower carbon impact than other solutions made of plastic on the market. Indeed, by replacing plastic with paper the carbon footprint of this product is 31%* lower compared to standard complex foils.

In addition, ESSENTIELLE contains approximately 60% aluminum, a recyclable material. The recyclability of aluminum is attested by the TREE assessment tool by CITEO**, when combined with glass recycling in France. Aluminum also retains the product’s aesthetic properties. It fits the bottle perfectly and can be customized according to market requirements.

A key element of this innovation is that Amcor Capsules guarantees that its customer’s bottling and packaging process, as well as its productivity, is unchanged. And, as the world’s biggest producer of Champagne, with production lines capable of handling more than 12,000 bottles per hour, productivity is a top priority for Moët & Chandon.

“The launch of the ESSENTIELLE plastic-free foil draws attention to the expertise at our Mareuil-sur-Aÿ site, which specializes in the manufacture of foils and is located in the heart of the Champagne region. Amcor Capsules is drawing on ESSENTIELLE to revolutionize the industry by offering a recyclable, plastic-free solution that suits the fast pace of their packaging lines, confirming its major role among wine-growing players, here in Champagne,” said Yannick Magnon, Managing Director of Amcor Capsules.

This innovation takes part in Amcor Capsules’ TRANSPARENCE program that was developed in July 2023 to reduce its environmental impact. TRANSPARENCE has already allowed Amcor Capsules to integrate more than 90% recycled tin in capsules and sparkling foil, as well as incorporating up to 46% recycled aluminum in screw caps for the still wine and spirits’ segment.

ESSENTIELLE also rises to the challenges faced by the world of Champagne and sparkling wine, which is moving toward more responsible solutions.

“At Moët & Chandon, we are proud to support and accelerate innovation within the Champagne sector. For over 10 years, we have been spearheading initiatives to reduce our environmental impact and cut carbon emissions. As such, our products are developed and analyzed to improve their environmental performance. Our goal for 2024 is to take this even further, and working with Amcor Capsules on the ESSENTIELLE foil reflects this commitment,” said Sibylle Scherer, President & CEO, Maison Moët.

The ESSENTIELLE foil will be produced at the Mareuil-sur-Aÿ site in Champagne starting in October 2024. Initially, the solution will only be available with texturing (standard or customizable) to allow sparkling wine players to retain the premium look of their bottles and the productivity of their packaging lines. The ESSENTIELLE foil with a smooth finish will be available during the first quarter of 2025.

* Comparison based on a comprehensive “cradle to grave” life-cycle analysis of basic packaging (standard APA structure: aluminum/PE/aluminum: 12/60/12 or 76 microns of caliber 34x122 – 4°22) compared to the suggested packaging (aluminum and paper structure in caliber 34x122 – 4°22) assuming 100% mechanical recycling for the aluminum part and 100% incineration with energy recovery for the other components — in both cases. Carried out using our ASSET Life Cycle Assessment (LCA) tool, verified by Carbon Trust.

** TREE is a recyclability-assessment tool designed by Citeo and is available on the customer portal. Citeo is a French organization with a social and environmental purpose (entreprise à mission) and was created so that companies in the consumer goods and distribution sector could reduce the environmental impact of their packaging and paper by offering them reduction, reuse, sorting and recycling solutions.

Amcor Capsules is preparing to launch ESSENTIELLE, a plastic-free foil made of aluminum and paper. By replacing plastic with paper, the carbon footprint of this product will be 31% lower compared to standard complex foils.

Courtesy of Amcor Capsules

Amcor Capsules is preparing to launch ESSENTIELLE, a plastic-free foil made of aluminum and paper. By replacing plastic with paper, the carbon footprint of this product will be 31% lower compared to standard complex foils.

Courtesy of Amcor Capsules

COLLAPSE ARTICLE ABOVE

Bx

xx

READ MORE

xx

T.

Courtesy of

COLLAPSE ARTICLE ABOVE

About the author

XXX