LEADING THE WAY ON TRACK & TRACE

Track and trace solutions are critical for product safety, preventing counterfeiting and achieving supply chain transparency. These companies are making names for themselves in the sphere of traceability and serialization.

By Brad Addington

Headline

Subhead

Byline

Double-click to select video

AN

T.

By B

The global track and trace solutions market size was estimated at $4.9 billion in 2022 and is expected to grow to $28.9 billion by 2032, according to Precedence Research.

Food and beverage, pharmaceuticals, health care, and medical device companies require a proper tracing of production and sales to enhance efficiency. Furthermore, serialization solutions provide manufacturers with the data needed to achieve compliance with evolving government mandates and regulations around product traceability.

In the first of the three stories presented below, David González of MM Packaging looks at some of these evolving government mandates and explains how his company addresses the common pain points for pharma customers that are striving to achieve traceability compliance.

The second story looks at how Antares Vision Group developed a traceability solution for cosmeceutical skin care solutions provider Episciences, Inc. Given the high value, high-leverage nature of its products, Episciences found itself particularly susceptible to gray market diversion.

Finally, we take a look at Deitz Co.’s innovative solution for automating traceability coding on bottle bottoms.

MM Packaging, Antares Vision Group and Deitz Co. are just three firms making headlines for paving the way to smarter track, trace and serialization solutions.

Caption

Courtesy of xxx

Left: XXX

Courtesy of xxx

Right: XXX

Courtesy of xxx

Text

Caption.

Courtesy of xxx

caption.

Courtesy of xxx

ADVERTISEMENT

xx

The Evolution of Serialization and the Role of Packaging

By David González, Technical Account Manager, MM Packaging

It’s clear that the packaging industry has a central role to play in supporting the long-term success of the pharmaceutical and health sectors. Technological developments have allowed packaging to go beyond simply containing products securely, to support areas such as patient safety and compliance in new ways. One of the most transformative journeys has been that of serialization.

Serialization, the process of assigning each individual unit of packaging a unique identifier, has come a long way from its early use to the stringent global regulations we see today. Today, it’s a vital tool in ensuring the products that reach patients are safe and validated, but there is still further work to do in making serialization a streamlined part of packaging workflows.

The principles behind coding began with the market realization that to increase security, particularly in a world where counterfeiting is on the rise, supply chain integrity had to be central. The World Health Organization reports that in some countries, as much as 10% of drug products on the market may be illicit or fake, putting patient safety in jeopardy. The problem also brings major challenges in commerce. The European Intellectual Property Office (EUIPO) reports that in the EU alone, counterfeit medicines cost the pharmaceutical industry more than €10 billion annually, representing the loss of almost 38,000 pharmaceutical jobs.

READ MORE

In response, serialization began as simple barcoding on single drug units. However, today’s data systems are much more sophisticated, capable of transferring a great deal more information. With serialization systems in place, drug products are continually collecting data from the point of manufacturing to the dispenser. The growth of this technology has created new needs for standardization, so we have seen initiatives such as GS1 coding standards become more prevalent.

The rise of serialization has been accelerated by key regulation changes that have shaped its implementation around the globe. The European Union Falsified Medicines Directive (EU FMD) and the US Drug Supply Chain Security Act (DSCSA) are prime examples.

The EU FMD, effective since February 2019, mandates the verification of prescription medicines at the point of dispensing, with the aim of combatting counterfeit drugs and protecting the safety of patients. Each medicine pack is required to have an identifier encoded in a 2D data matrix barcode, with the data uploaded to a European repository by the manufacturer.

Similarly, the DSCSA, enacted in 2013 and set to be fully enforced by November 2024 following a year-long ‘stabilization period’, established a standardized national system for tracking prescription drugs through the supply chain in the US, which also requires a 2D data matrix barcode. These codes must contain a variety of information, include National Drug Code (NDC), expiration date and serial numbers. Further afield, countries such as China, South Korea and Russia have also introduced specific serialization regulations, reflecting a global commitment to securing pharmaceutical supply chains.

With regulations in place, pharmaceutical companies have heavily invested in serialization technologies to comply with these mandates. This investment is not just about meeting regulatory requirements; it’s about transforming how medicines are tracked and traced, ensuring authenticity at every single stage.

As pharma packaging suppliers, we have a crucial role to play in supporting patient safety and to do that, we must effectively anticipate changing customer needs. In today’s market, our collective focus needs to be on robust, fail-safe serialization solutions that ensure every unit of medication can be tracked and verified throughout its journey from production to patient. Alongside in-depth knowledge of the market, this requires complete commitment to innovation, quality and precision, as well as investment in the latest serialization and coding technologies.

An integrated and in-line approach to serialization within the packaging development and production process not only enhances efficiency but also provides greater control over the entire supply chain. In-house serialization means that pharma packaging suppliers can ensure faster turnaround times, reduce the risk of errors, and offer more agile responses to changing market demands. This agility is crucial in today’s dynamic pharmaceutical market, where regulations, technologies, and consumer needs are continually evolving.

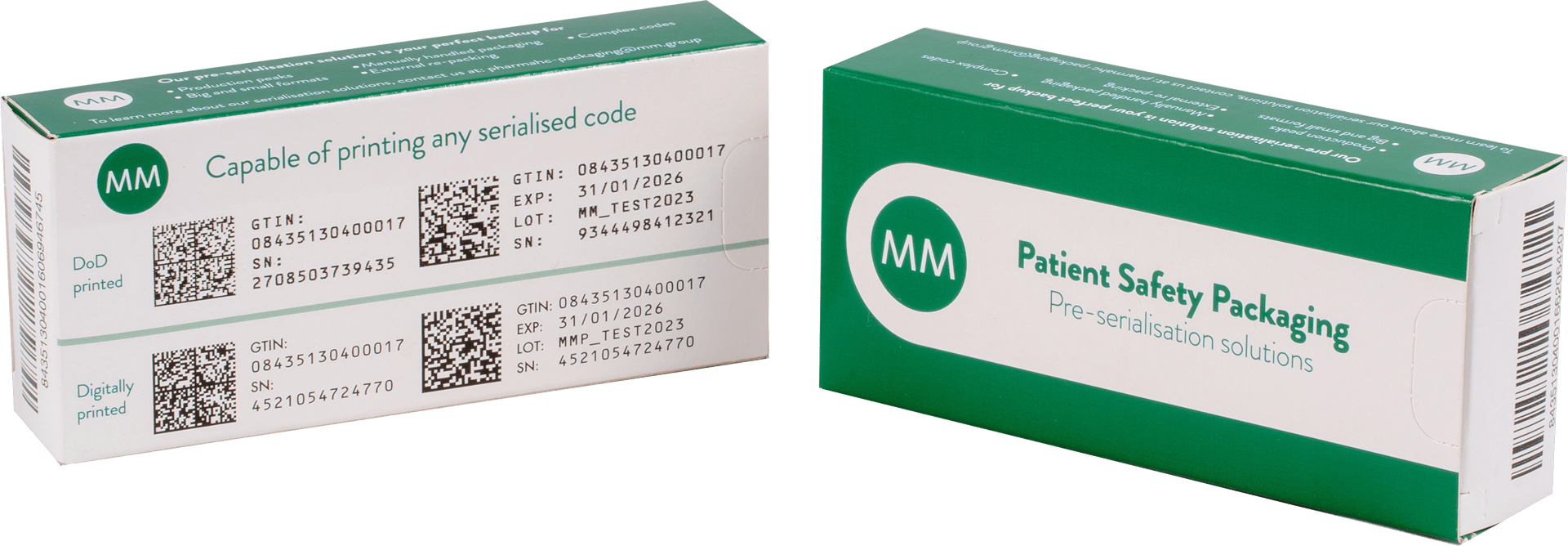

At MM Packaging, we show the power of agility and expertise in action, directly addressing common pain points for our pharma customers. For example, one problem could be a pharma business not getting the correct format or type of serialization for the market they’re operating in. To support our customers, we invest in many different printing technologies, allowing perfect grading and quality, even in more intricate code styles, such as those used in China or Russia. What’s more, with our experience and capabilities, we are able to offer serialization in large cases or unusual sizes, which gives us the ability to respond to flexible customer needs and deliver an outstanding finished product.

The key to success clearly lies in packaging partners providing comprehensive serialization services in house, helping pharmaceutical companies to stay ahead of regulatory changes, quickly adapt to new requirements, and maintain the highest standards of safety and quality.

Learn more about MM Packaging and its activities.

MM Packaging invests in many different printing technologies for serialization, allowing perfect grading and quality, even in more intricate code styles such as those used in China or Russia.

Courtesy of MM Packaging

COLLAPSE ARTICLE ABOVE

Antares Vision Group Completes First Phase of Serialization for Cosmeceuticals Provider

Antares Vision Group — a technological partner in the digitalization of products and supply chains for companies and institutions, and leader in traceability and inspection for quality control — has implemented the initial phase of a robust traceability solution for cosmeceutical skin care solutions provider Episciences, Inc.

Addressing needs for enhanced supply chain visibility amid substantial gray market diversion challenges, the sophisticated track & trace system was developed by ACSIS, a business unit of Antares Vision Group providing seamless serialization solutions.

Based in Boise, Idaho, Episciences is the exclusive manufacturer and distributor of the Epionce skin care line. Sold through the medical channel, clinically proven Epionce products are produced in an FDA-inspected drug manufacturing facility. Notably, Epionce skin care was the first skin care line on the market to be focused on the health of the skin barrier. Its products are sold throughout the United States, as well as internationally.

Given the high value, high-leverage nature of its products, Episciences found itself particularly susceptible to gray market diversion. In part due to its sheer product breadth — the company manufactures more than several dozen unique offerings — conventional serialization solutions struggled to provide an adequate end-to-end solution. Printability, coding recognition, and false rejects were particularly vexing issues.

READ MORE

The ACSIS Serialization Management solution manages, applies and captures serialization data at the unit, bundle, carton and pallet level, providing manufacturers with the data needed to achieve compliance with evolving government mandates and regulations around product traceability. In doing so, the solution provides seamless integration with enterprise systems such as ERP, MES and serialization repositories, as well as line-level equipment like vision technologies, printing components and packaging automation modules.

Along with robust serialization functionality, the Serialization Management solution can also capture user-defined product attributes at the point of serialization, yielding useful insights to help optimize various points along the value chain. Notably, ACSIS’ user-friendly architecture makes defining and changing data collection parameters efficient and intuitive.

At Episciences’ plant, ACSIS’ Serialization Management system operates on two packaging lines. Its software manages the vision systems, printers, and barcode readers necessary to verify and capture product serial numbers. The system is also the primary user interface for product selection and serialization verification data entry.

Especially important given its broad range of Epionce products, Episciences was able to integrate ACSIS’ Serialization Management system without the hassle and cost of modifying existing secondary packaging artwork or labeling procedures to prioritize barcode placement. This ability to retain its existing carton surface composition exemplifies the disruption-free nature of the overall system.

“The system ACSIS employed for our Epionce products is both highly customized and essentially turnkey, with bare minimum ramp-up and training required,” said Ron Hope, General Manager of Manufacturing & Distribution for Episciences, Inc. “Critically for a manufacturer with a diverse array of products, initiating new SKUs is a smooth process that doesn’t delay the inception of commercial-scale production.”

“The ACSIS solution is the foundation that Episciences is using to build a full end-to-end supply chain traceability platform,” said John DiPalo, Chief Strategy Officer at ACSIS. “By leveraging the complete ACSIS solution, Episciences can track product from packaging through distribution and across the extended supply chain.”

Antares Vision has implemented the initial phase of a robust traceability solution for cosmeceutical skin care solutions provider Episciences, Inc.

Courtesy of Antares Vision Group

Antares Vision has implemented the initial phase of a robust traceability solution for cosmeceutical skin care solutions provider Episciences, Inc.

Courtesy of Antares Vision Group

COLLAPSE ARTICLE ABOVE

Deitz Co. Develops New Printer Mounting Kit for Traceability Coding

A new printer mounting kit from packaging machinery manufacturer Deitz Co., Wall, New Jersey, enables food, pharmaceutical and nutritional product manufacturers to mount a printer underneath the company's PharmafillTM BCV1 Bottomless Conveyor and automate lot traceability coding on bottle bottoms. Comprising a mounting bracket with hardware, the new printer mounting kit attaches to the conveyor's adjustable-height lift stand to accommodate a wide range of laser marking devices, thermal inkjet printers, continuous inkjet printers or other coding systems. With the kit and desired coding system installed, lot traceability information may be automatically added to bottles, tins, jars, and other containers without stopping the line or manually removing, rotating, or diverting the containers.

READ MORE

With the kit and coding system installed, the Bottomless Conveyor automatically accepts the filled bottles from a conveyor, grips them between dual hugger belts, and moves them over the printer to automatically apply the lot traceability codes on the bottle or container bottom while still in motion. When complete, the marked bottles are automatically transferred downstream without interruption.

The printer mounting kit and Bottomless Conveyor are designed and manufactured at the company's Wall, New Jersey, headquarters. Testing is offered on the company's in-house testing/training filling and packaging line.

Learn more about Deitz Co.

A new printer mounting kit from Deitz Co. enables food, pharmaceutical and nutritional product manufacturers to mount a printer underneath the company's PharmafillTM BCV1 Bottomless Conveyor and automate lot traceability coding on bottle bottoms.

Courtesy of Deitz Co.

COLLAPSE ARTICLE ABOVE

Bx

xx

READ MORE

xx

T.

Courtesy of

COLLAPSE ARTICLE ABOVE

About the author

XXX