Brand Protection,

Pill Protection &

Aesthetic Appeal

The myriad functions of foil in CPG are exemplified by these developments that made headlines in 2023.

By Brad Addington

Foils are ubiquitous in CPG and have countless uses and applications. In this article, we look at foil packaging from three different but equally intriguing perspectives.

- First, we look at the recent launch of a new version of BOBST’s NOVAFOIL 106 hot foil stamper, dedicated to the application of holograms. This new offering ties into the key issue of brand protection.

- Second, we look at how a company’s choice of printing equipment can reduce waste when using foil in pharmaceutical blister packs.

- Finally, we look at a really fun aspect of foil in packaging, namely, the use of foil to greatly enhance the aesthetic appeal of CPG packaging.

ADVERTISEMENT

BOBST’s new hologram application system uses connected tools to maximize efficiency

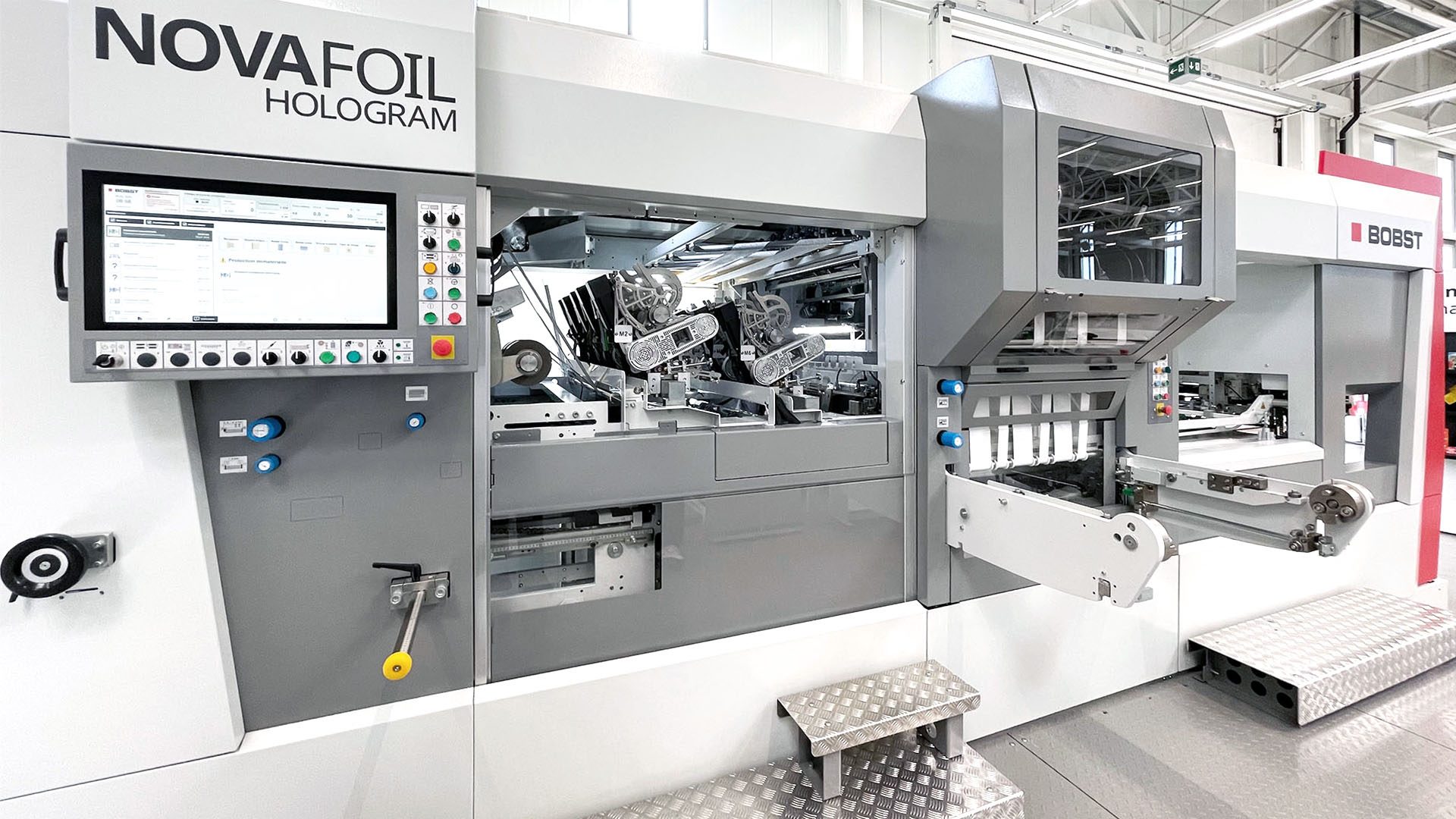

Building on the innovative technology of the NOVAFOIL 106, BOBST has launched a new version of the hot foil stamper, dedicated to the application of holograms. Featuring a completely redesigned hologram application system, the NOVAFOIL 106 H gives converters maximum flexibility and efficiency for hot stamping transfer with holograms.

Only two years ago, the NOVAFOIL 106 was introduced. It was the first inline hot film-stamping machine from BOBST offering an advanced cross-foiling option, increasing its efficiency and versatility. It also offered a new level of embellishment quality with its redesigned platen section – ensuring longer dwell time, stable platen temperature and higher pressure. Reliability, coupled with cost-efficient foil use and great flexibility, is also the basis for the new version of this compact and productive machine.

READ MORE

BOBST earlier this year launched a new version of its NOVAFOIL 106 hot foil stamper, dedicated to the application of holograms.

Courtesy of BOBST

Being conscious of the particular needs of hologram application, BOBST wanted to provide an option for converters who specialize in this area of hot transfer. The result is a new system with individual hologram modules, which can be mounted on rails on the NOVAFOIL 106. With up to 2 rails and 5 modules each, 10 hologram reels of maximum 100 mm width can now in one single pass convert jobs which previously required two runs.

To guarantee the zero-fault quality that customers expect, the NOVAFOIL 106 H has been equipped with a register for every reel to ensure perfect application precision. The film advance is controlled via an electronic system, and advance shafts with pressure rollers ensure perfect film tension.

The modules can be positioned rapidly, and the hologram reels can be introduced within seconds. What is more, the modules can be directly plugged into one of two connecting boxes on each side of the machine. This “plug and play” system ensures quick and hassle-free changeovers.

To cut down setup times even further, BOBST has also introduced the Digital Makeready Tool (DMT). Inspired by the Digital Inspection Table (DIT) quality control solution, the pdf of any embellishment job can be sent to the DMT, where the digital layout is projected directly onto the honeycomb chase. This projection indicates precisely where the dies have to be positioned, eliminating lengthy setup checks. The DMT shortens setups and increases accuracy to ensure impeccable stamping register quality, which in turn reduces the number of waste sheets.

Everything has been considered to make sure owners of a NOVAFOIL 106 H can expect flexible use, short setups, and maximum precision for premium brand protection with hologram application.

To find out more about BOBST and its products designed for the folding carton sector, please visit Bobst.com.

COLLAPSE ARTICLE ABOVE

In-line Digital Printing and Waste Reduction

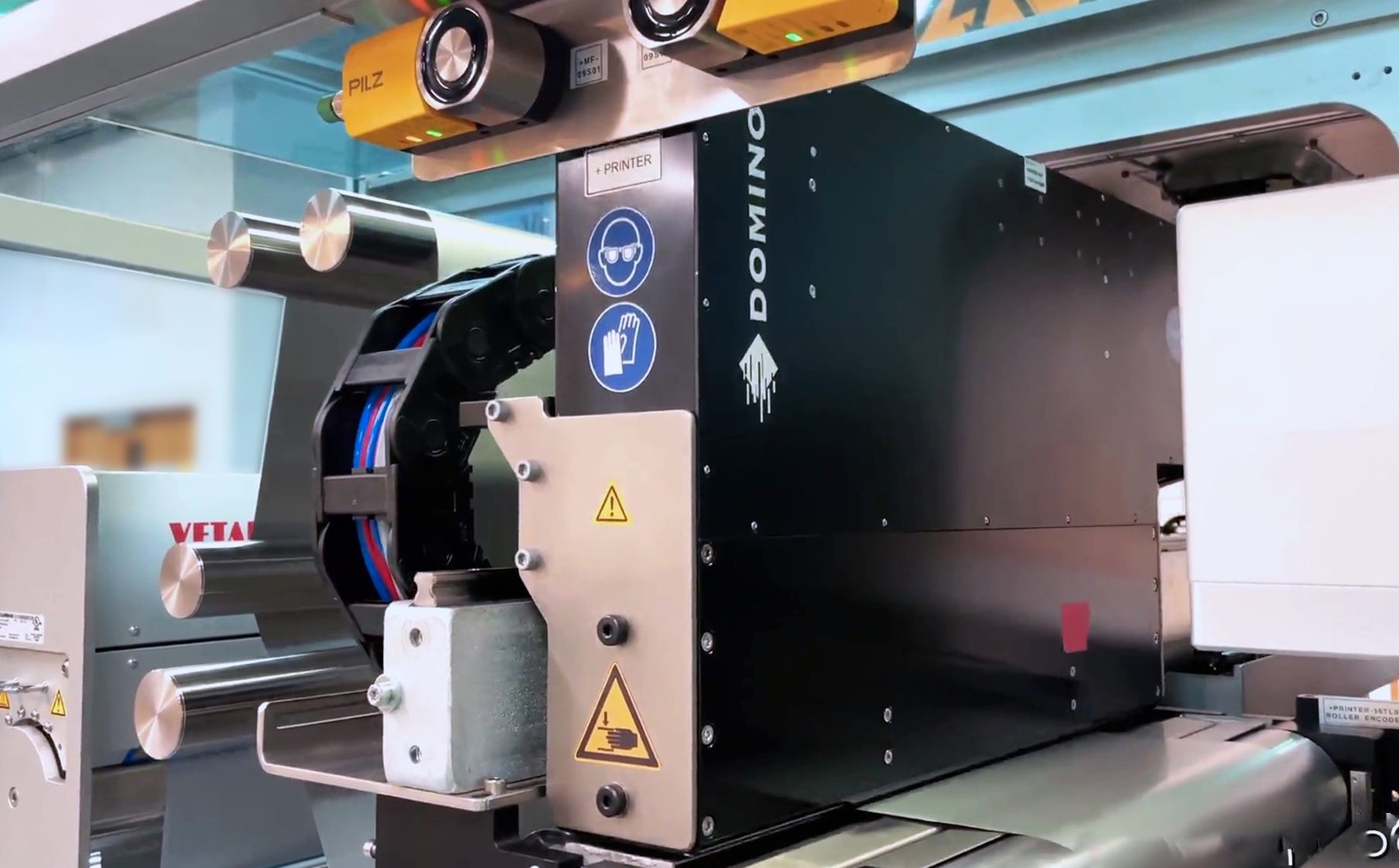

Earlier this year, Packaging Strategies reached out to Craig Stobie, Director of Global Strategic Sectors, Domino Printing Sciences, about the role of in-line digital printing in reducing waste in blister pack printing. Here is what Stobie had to say:

The pharmaceutical sector, and, in particular, blister pack printing is one example where in-line digital printing is helping manufacturers to reduce waste, improve efficiency, and increase line agility. Until recently, most pharmaceutical manufacturers would buy blister foils pre-printed with product names, dosage information, and branding and use a basic in-line printing or embossing system to add a batch code and expiry date to the blister in human-readable text.

Introducing in-line digital printing, with applications such as Domino’s K600G, provides additional flexibility and can allow manufacturers to respond much more quickly and efficiently to changes in print requirements. In the past, manufacturers would typically have to wait several days or even weeks for pre-printed foils to arrive in the event of a change in product design. With in-line digital printing, manufacturers can switch from one design to the other in a fraction of the time. The technology also makes it economically viable to do much smaller batches.

READ MORE

In-line digital printing, with applications such as Domino’s K600G, can allow manufacturers to respond much more quickly and efficiently to changes in print requirements, including changes in blister pack printing requirements.

Courtesy of Domino

When investing in a digital in-line printing solution, the price difference between a narrow printhead that is only suitable for printing variable information (i.e., 2D code, batch code, and expiry date), and a wider printhead that can also print larger graphics, including artwork, is often negligible compared with the possible savings. Wide web digital printing allows manufacturers to purchase only blank foils and carry out complete coding in-house, reducing stock requirements and inventory space. In addition, a significant saving can be made, as blank foils are less expensive than pre-printed, even when accounting for the cost of ink.

This new approach can also allow for significant waste reduction, helping pharmaceutical manufacturers reduce their environmental impact. Manufacturers typically order 10-20% extra when purchasing pre-printed foil to allow for unforeseen issues or wastage from set-up and product changeovers. However, in practice, they rarely need to use all the excess foil, and any excess may be discarded. This is not an issue with blank foils, as manufacturers can reuse excess foil for subsequent print runs.

Much development has been done in the last couple of years to increase the availability of suitable digital printing inks for pharmaceutical coding. UV curable inks are a standard application for metallic foil printing, and there are now many Swiss-List-approved, CMR-free variants available. There are also many water-based options suitable for paper-based packaging that deliver as much contrast as the classic UV drying inks – these are suitable for use in flexible papers, which are growing in popularity as blister pack seals.

COLLAPSE ARTICLE ABOVE

Premium Labels & Packaging Solutions Wins Bronze at FSEA Gold Leaf Awards

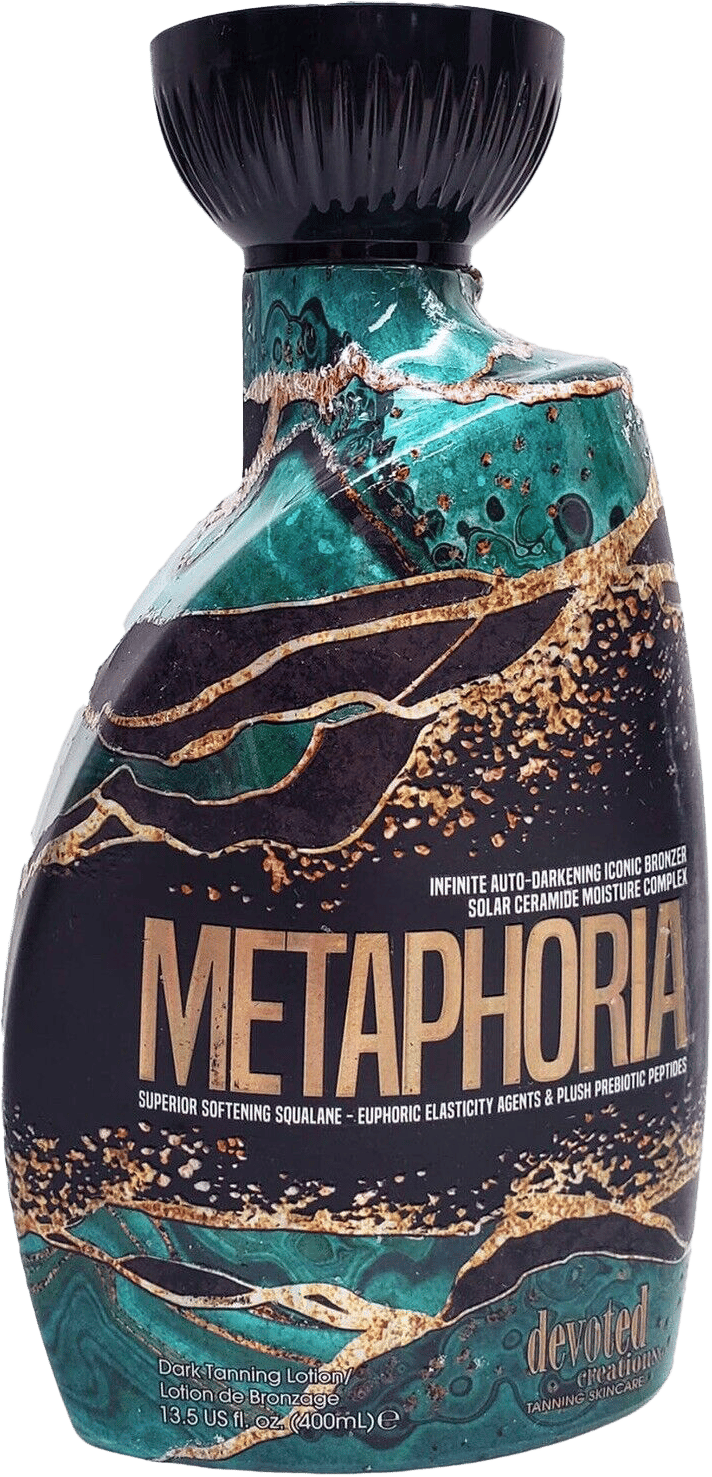

Premium Label & Packaging Solutions announced in June that Overnight Labels, its facility located in Deer Park, New York, won a Bronze Award at the 30th Annual Gold Leaf Awards for Best Use of Cold Foil (Label or Carton).

The winning label is a shrink sleeve produced for longtime client OL Products for Metamorphia Tanning Lotion. The luxury ingredients inside of the bottle pair perfectly with the green, black, and gold “marble” packaging design that exudes opulence.

To achieve the multi-faceted look, Overnight Labels used a holographic foil and applied a spot matte to sections of the black. To add dimension and a tactile effect, a UV silkscreen was applied to the gold, which increased the complexity of the printing process.

READ MORE

Known for its expertise in both specialty finishes and shrink sleeves, Overnight Labels has won numerous industry awards. Chris Payne, CEO of Premium Labels & Packaging Solutions, said, "We always strive to maintain a level of excellence for everything we print, especially when a job calls for intricate details. We are honored that the judges recognized us for our craftsmanship.”

The competition evaluates submissions that utilize a wide range of specialty finishing techniques, from foil stamping and embossing to specialty coating, film laminating, laser cutting, die-cutting, and cold-foil applications. A record number of entries were received from countries worldwide, including the United States, Canada, India, Italy, Switzerland, Poland, Denmark, Japan, South Africa, and Taiwan.

“Our FSEA Gold Leaf Awards Competition showcases how embellishments have become a catalyst in the printing industry,” says FSEA executive director Jeff Peterson. “The creativity and technology used in the pieces we receive continue to amaze us every year, from greeting cards and book covers to folding cartons and labels.”

Premium Label & Packaging Solutions was formed in 2021 to bring together a group of award-winning converters with decades of experience in the Pharmaceutical, Nutraceutical, Beauty, Food & Beverage, and Household Product industries. Forming one company with redundant capabilities, a large fleet of state-of-the-art equipment, and market proficiency offers the personal touch of a small business with the infrastructure of a large organization and a unique quick-turn model that puts exceptional quality, speed, and customer service first. They supply pressure sensitive labels, shrink sleeves, extended content labels, and flexible packaging to CPG companies nationwide.