The Future of

Human Machine Interfaces 4.0

With touch displays, remote control and other advances, HMIs are now a part of everyday machines.

By Kristen Kazarian, editor in chief

The HMI market was valued at U.S. $4.3 billion in 2020 and is expected to reach $5.6 billion by 2025, at a CAGR of 5.2% during the forecast period (ResearchandMarkets). Factors driving growth include the surging adoption of industrial automation in the manufacturing sector, the evolution of industrial internet of things (IIoT), growing demand for smart automation solutions and rising need for efficiency and monitoring in manufacturing plants.

Embedded HMIs are anticipated to capture the highest CAGR, as they offer an integrated environment that is much simpler and user-friendly, and helps in enhancing efficiency. Growing technological developments in manufacturing, increasing need for integrated systems, and ease in machine-to-machine communication are some reasons expected for adoption of this configuration.

I spoke with John Koke, VP of Technical and Strategic Innovation at BW Packaging Systems; Mike Burns, Global Director of Strategic Marketing and Innovation at Accraply; and Tec Wright, U.K. Director of Engineering at Accraply, about the future of the HMI market.

From left to right: John Koke, VP of Technical and Strategic Innovation at BW Packaging Systems; Mike Burns, Global Director of Strategic Marketing and Innovation at Accraply; and Tec Wright, U.K. Director of Engineering at Accraply, about the future of the HMI market.

Photos courtesy of BW Packaging Systems and Accraply, Barry-Wehmiller Packaging Companies

How have human-machine interfaces changed in the last few years?

Burns: There have been rapid advances in human-machine interfaces in the last three years or so, HMI functionality is becoming a differentiator in the market space. Customers are looking for smarter machines with more connectivity. They are seeking greater insight into their labeling operations and looking to leverage technology to increase productivity.

Koke: Today’s HMIs offer significant advances in user experience including improved graphics, enhanced connectivity, larger screen sizes and multi-touch functionality. They provide greater access, not only to a machine in its current state, but also to information that can be used to improve the machine’s performance throughout its lifecycle. BW Packaging Systems' HMIs, for example, include access to manuals, training, user guide set-ups, preventative maintenance, OEE optimization, and remote support.

The Smartlink HMI's intuitive layout makes screens easily navigable. Advanced analytics are available, allowing overall efficiencies, availabilities, performance and quality to be analyzed in real time.

Photo courtesy of Accraply, a Barry Wehmiller Packaging Company

How about with your own companies?

Burns: For labeling application systems, Accraply made significant advances in HMI and controls structure in 2020. Our new SmartLink HMI, which comes standard on the Sirius Advanced MK6 Labeling Machine and is available as an optional add on with the Sirius 100 series of labeling machine, makes pressure-sensitive labeling operations more intuitive, efficient and easily accessible. It was designed to help users leverage technology to optimize their labeling process at the machine or from a remote location. For example, operators can access machine configuration and set-up audit trail information in person or offsite.

The intent behind the SmartLink was to help users increase uptime and throughput by providing critical information regarding the machine’s availability, performance and condition. It is designed to accommodate rapid changeovers, store recipes and provide video changeover guides to assist operators and reduce downtime.

We’ve also received feedback from our customers that SmartLink has helped simplify their operator training too. The HMI includes video tutorials and on-demand training guides to make set-up and operations simple. Preventive maintenance schedule displays daily, weekly and monthly tasks for your operator and maintenance team. On-board manuals, drawings and consumable parts ordering enable the operator to find information and submit parts orders by utilizing the HMI.

Koke: In parallel to Mike’s comments, we’ve also developed a new HMI for the Hayssen ISB, the newest sanitary VFFS bagger from BW Flexible Systems, another of our BW packaging companies. This HMI also includes user-focused advances including:

- Step-by-step setup guides for key functions, maintenance and fault recovery processes

- User levels: Access and Accountability — to drive consistency of performance — access to parameters and/or range of adjustment can be set by user level. Machine adjustments are tracked by an individual.

- Fully functional recipe management system to drive consistency and performance

- Productivity Reporting – performance, OEE, trend analysis, fault statistics, etc.

- Connectivity – remote access and secondary HMIs

- Ease of Use – compliance with ANSI 101 HMI standards

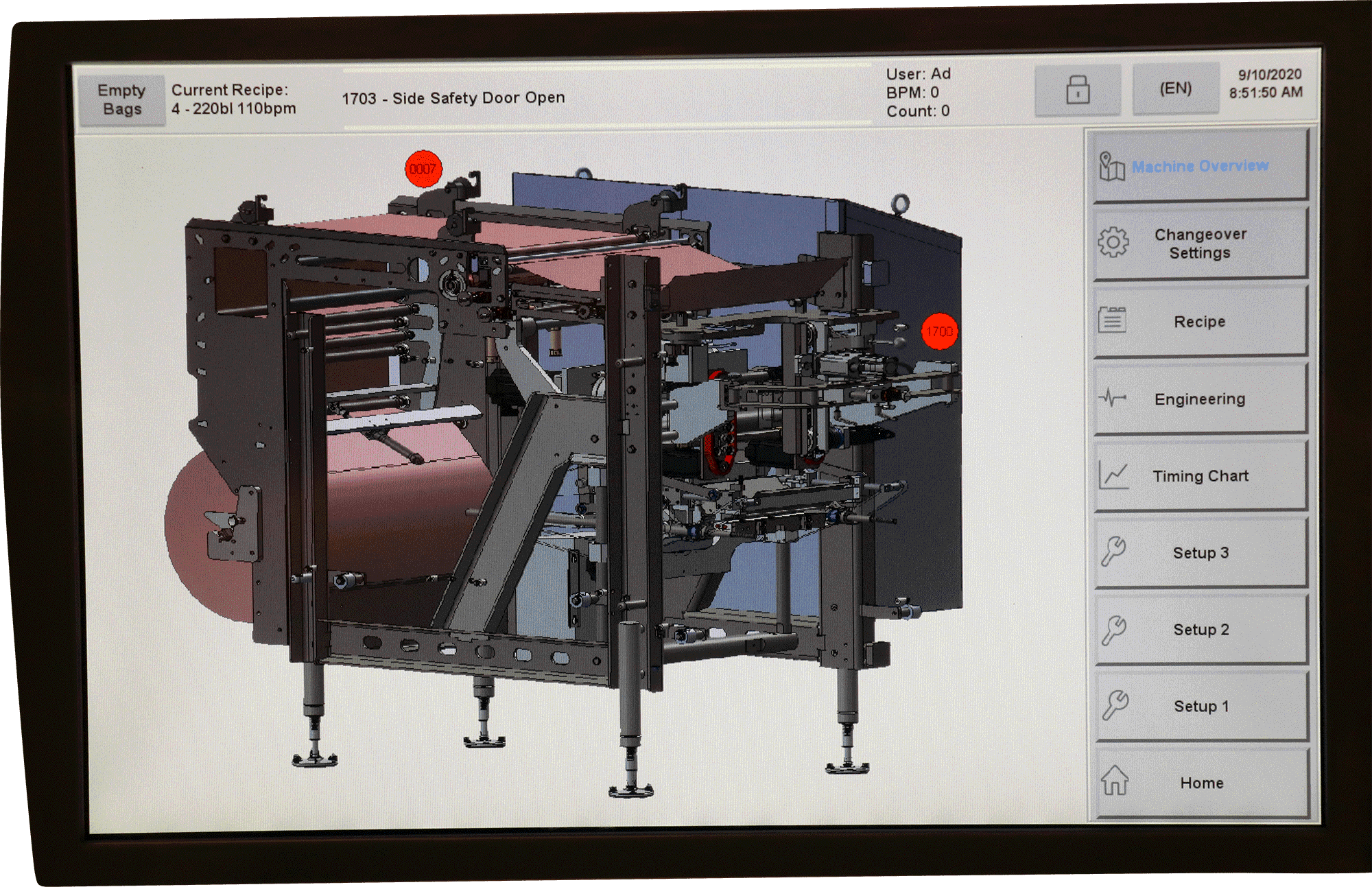

Embedded HMIs now have the processing capabilities to improve the interface. Rather than the flashing warning light of years gone by, today’s system designers can display an image of the machine and more.

Photo courtesy of BW Flexible Systems, a Barry Wehmiller Packaging Company

Are embedded HMIs growing faster than other types?

Wright: Most HMIs are embedded these days. The embedded bit just means the screen is an all-in-one, including an interface, touch screen, (sometimes PLC), with graphic drivers for video and some processing power to handle data. They are growing fast, as they are the latest technology and are easily interfaced with good connectivity. They offer users the opportunity to have one interface instead of multiple.

Embedded HMIs offer increased usability to the manufacturer and, more importantly, the user. The ability to show complex data in real time, such as machine OEE (to show operators where a fault lies as well as offer remedies to fix the fault), on screen and in real time via video assistance is a powerful tool. Add to this the ability to connect remotely to other devices safely and securely; it offers a level of machine/plant visibility not previously available without very expensive additional IT infrastructure.

Koke: With embedded HMIs, we now have the processing capabilities to improve that interface. By increasing the processing power available to system designers, we can analyze and present system information in a more usable manner. Rather than the flashing warning light of years gone by, today’s system designers can display an image of the machine, place an indicator where the exact fault is, provide links to instructional steps to clear the fault, walk the operator through the steps to resolve the fault and reset the machine. No manuals have to be consulted, the issue is addressed on the spot, minimizing downtime and improving operation efficiency and operator skill levels. The same can be done when it comes to preventative maintenance and maintenance activities on the screen.

We are leveraging this technology in our recent developments to provide an improved user experience and to help our customers run more efficient operations and bring their employees to higher competency level faster by leveraging the capabilities of the embedded HMIs.

The Smartlink HMI aids operator setup and reduces downtime with video tutorials that advise the operator on routine maintenance tasks.

Photo courtesy of Accraply, a Barry Wehmiller Packaging Company

The advanced panel-based HMI market is anticipated to witness great growth due to demand of mobile HMIs. Is this due to COVID-19 and the need for more mobilization in plants/warehouses?

Burns: Advanced panel-based HMIs, such as the SmartLink HMI, are forecasted to achieve a high market growth rate due to the demand for mobile HMIs. The ability to connect with a machine remotely and to access all the information required to provide greater insight into labeling operations, and thereby increase the overall productivity of the plant, is more desirable than ever. COVID-19 has served to reinforce the importance of remote connectivity and simplification of operations. The SmartLink system enables our customers to increase uptime and throughput, simplify operator processes, and leverage technology to enhance overall labeling processes.

Koke: Having the ability to make machine HMI information mobile has enabled new and powerful use cases. One use case is when dealing with large machines it allows us to bring information to the point of use, where it is needed. For example, on the new BW Flexible Systems Hayssen ISB Vertical Bagger, we are using this capability to allow an operator to use a secondary mobile HMI to put step-by-step instructions in their hands as they perform machine set-ups. It is of little benefit to provide step-by-step instruction on an HMI at the front of the machine when some of the operations need to be done on the back of the machine, for example a roll change. With a mobile HMI, we have been able to put the instructions in the hands of the operator while optimizing the changeover process, both in terms of time and steps, driving plant efficiency and OEE.

Another aspect of this technology is more relevant in terms of the impact of COVID is that this technology has enabled remote service and access in ways only dreamed of before. Now we can put a service expert in the plant using video, audio and annotated images to guide maintenance and repair remotely, again, right at the point of use. This type of value and efficiency gains were in the technology and in time were going to be leveraged to improve visibility and efficiency of operations. What we can say is that COVID has certainly sped up the adoption and value that it brings!

HMIs should be designed to enhance productivity and increase throughput, be user friendly, offer enhanced reporting & preventative maintenance schedules and alerts, and support higher levels of product support through remote access.

Photo courtesy of BW Flexible Systems, a Barry Wehmiller Packaging Company

What are 5 features that companies should look for when adding HMIs to their production line?

Burns:

- HMIs must be designed to enhance productivity and increase throughput.

- HMIs should be user friendly – with stored recipes and changeover videos as well as visual troubleshooting guides for operators that are not text based (for those that are illiterate or can’t read English).

- HMIs should offer enhanced reporting and audit trails.

- HMIs should offer preventative maintenance schedules and alerts.

- HMIs should support higher levels of product support through remote access, maintenance support, spare part identification and spare parts ordering.

Opening feature photo by genkur / iStock via Getty Images Plus