Precision High-Volume Pack-n-Ship for

e-commerce Orders

Streamlined e-commerce fulfillment necessitates the use of automation to sustain high throughput, reduce freight costs and minimize the use of packaging materials.

By David Nettles, director of sales,

Texwrap Packaging Systems

Precision High-Volume Pack-n-Ship

for e-commerce Orders

Streamlined e-commerce fulfillment necessitates the use of automation to sustain high throughput, reduce freight costs and minimize the use of packaging materials.

By David Nettles, director of sales, Texwrap Packaging Systems

Growing at an average of 15% annually, e-commerce purchasing creates significant challenges for online retailers, who often struggle to meet the demands of buyers. E-commerce is inherently unpredictable. While some e-tailers fail to reach their goals, many others find their 10-year goals coming to fruition in only a handful of years. This sometimes erratic and chaotic pace places stress on companies to expand their production capabilities quickly in a way that generates a return on investment (ROI). E-commerce companies may quickly outgrow warehouse space and be forced to lease facilities or rely on third-party logistics, neither of which is ideal for long-term ROI or developing streamlined workflows.

E-commerce Fulfillment Challenges

Adding to the difficulties of rapid scaling are a number of technical e-commerce fulfillment challenges including:

Managing high volumes of SKUs

Small number of pieces per order

Peak season volumes can vary dramatically from other times of the year

Changes in market demand can lead to understocking

Increased expectation for same-day and next-day delivery

Higher number of returns compared to brick-and-mortar purchases

ADVERTISEMENT

These challenges require a flexible and scalable response from e-commerce companies. Pick, pack and ship capabilities must be able to track changes in the market and react immediately to them.

Automating such capabilities has typically been a luxury reserved for larger online companies. For small- to medium-sized e-tailers, the changes accompanying rapid growth can be particularly daunting. Many small online retailers handpick and handpack their orders. Paper-based operations are not uncommon. Inventory is often stored on the floor or on racks, with case picks and pallet picks used to fulfill orders. These systems are easily taxed by larger quantities of online sales, particularly those with multiple-SKU orders. Such e-commerce companies need a solution for efficient throughput that can scale upward as they grow.

Forward-thinking e-commerce companies must predict what their demand will be several years down the road. If projections favor increased sales, they may invest in systems that automate their end-of-line fulfillment processes. These systems must be capable of managing high volumes of throughput with real-time visibility while maintaining precise accuracy.

Advanced Automation for e-commerce Fulfillment

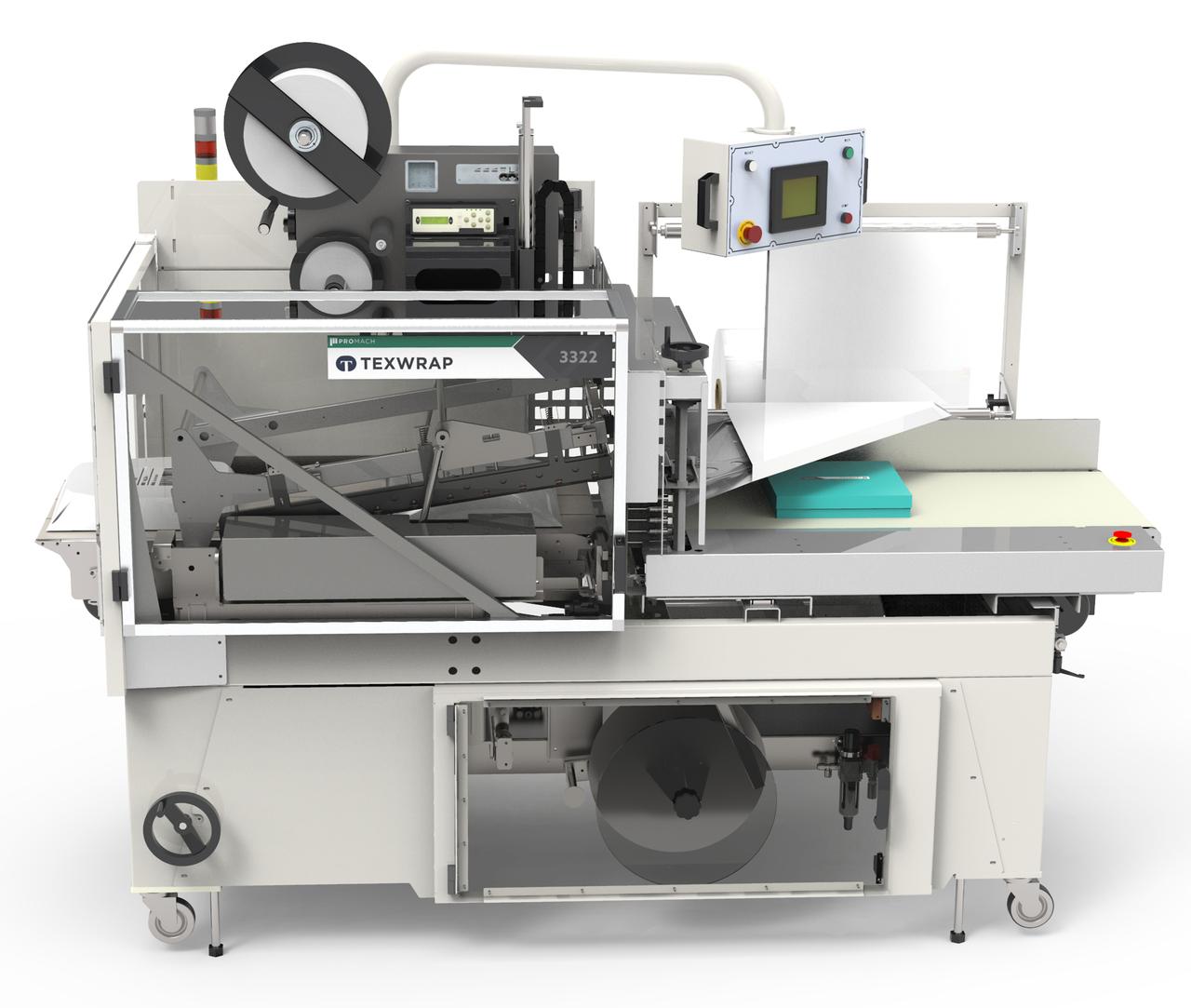

An example of an automated e-commerce fulfillment system is the Model 3322 ePack Auto-Mailer from Texwrap Packaging Systems (Texwrap) — a U.S. manufacturer of automated shrink wrapping systems. This auto-packaging and labeling system incorporates some technology into one fully integrated, high-speed system.

Products are received from upstream picking via conveyor, laser-scan-measured for dimensional weight, shrink-wrapped to size to create ready-to-ship mail packages, heat sealed closed, then labels and barcodes are printed and applied. Orders enter on one end then come out fully packaged and labeled in a flexible plastic envelope ready to ship at a throughput rate of 20 packages per minute.

Packages being conveyed into the ePack system.

Accurate Dimensioning of Packages

Companies are more incentivized than ever to pack their products in the smallest sized packaging possible. Manual measurement of dimensions is open to inaccuracies and requires additional time and labor, which can chip away at savings on shipping costs. It also creates a bottleneck in workflow. The use of one-size-fits-all packaging for a range of product sizes, while it may increase throughput, effectively translates to paying extra money to ship air. Warehouse management and cartonization software alone cannot solve this issue. It requires a comprehensive solution that is integrated with the entire workflow.

The solution is dimensional weight pricing — calculated as volume divided by weight, divided again by 166 — an agreed-upon industry dimensional constant by carriers like FedEx and UPS.

The ePack Auto-Mailer, for example, is able to measure the height, width and length of each package. This information is sent down-line so that the correct-sized flexible package is ready to be created. When the product reaches the process area, the wrapper fits a flexible polybag over it that is sealed to the correct size. As a result, as much as 50% can be saved on material costs. Pre-made polybags are typically too large for the products they envelop, which means companies are paying for material they are not using.

Products are laser scanned for size dimensions prior to entry into ePack.

Smart-Track Technology

High speeds are only beneficial if the system is accurate. The ePack Auto-Mailer features Smart-Track Technology and to reduce errors in order fulfillment.

Dimensions of the product are detected in order to generate the correct-sized packaging for it in later steps. By checking the consistency of the product’s size multiple times before it is wrapped, the system can ensure that the product now in place to be packaged is the same product that was originally scanned earlier on the conveyor. If the two do not match, the whole system pauses to allow the operator to correct the issue. If the two sets of scanned images do match, the product is fed in, sealed and labeled.

The Auto-Mailer is capable of handling the high volumes and SKU counts that e-fulfillment companies often experience during seasonal spikes. Its cycle times allow operation even when processing large numbers of transactions per hour and help correct labels attach to the correct product.

Wrapping Process

After the product is scanned and validated, the next process in the Auto-Mailer's chain of operations is wrapping.

The product is conveyed into the process area into a web of center-folded film. One end of the package is sealed from the previous package. The edge and ends are sealed, forming a completely sealed, mailable material around the product. The trimmed bag also creates a clean presentation for customers.

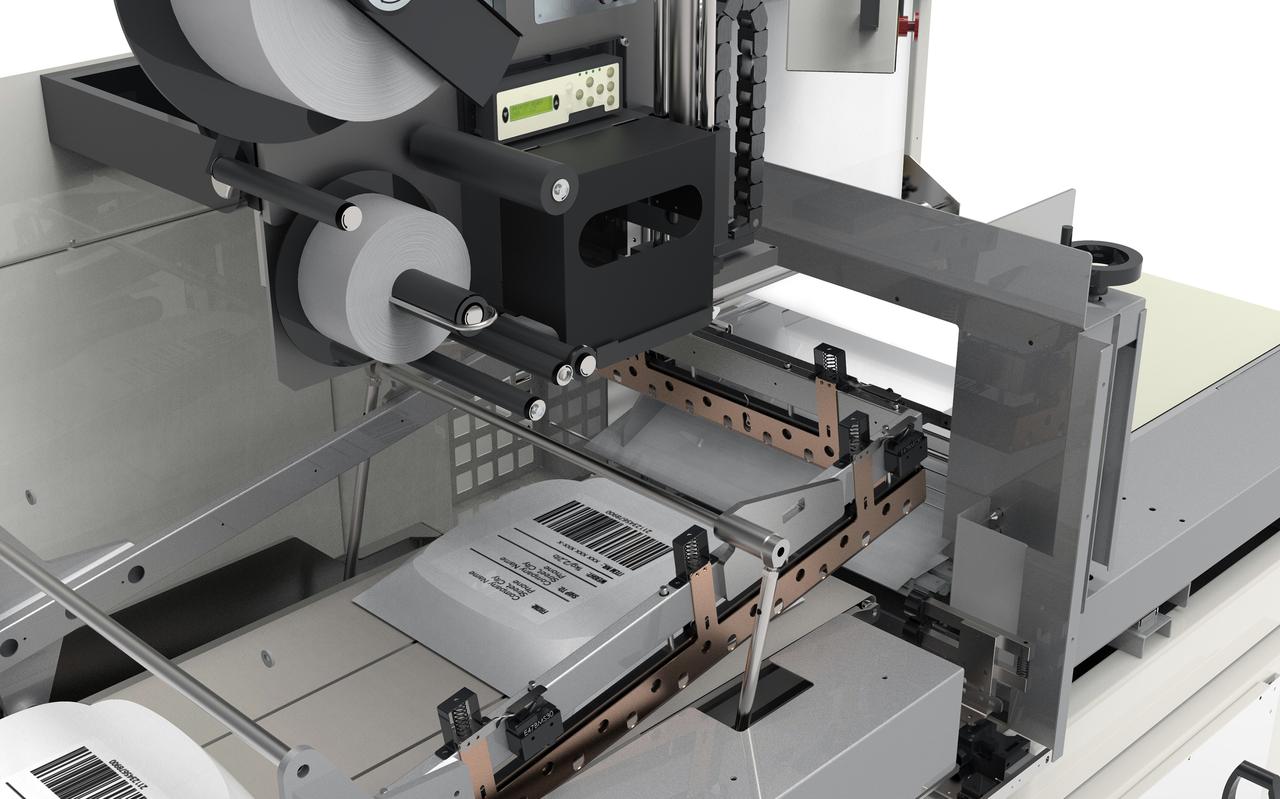

End sealing and labeling.

Package Labeling

After wrapping the product in a mailing envelope, the barcode is scanned and sends the proper address information to an ID Technology Model 252 print-and-apply labeler. This prints and applies a shipping label with address and shipping information.

This labeling step automates the process and checkpoints leading up to the final labeling procedure work in conjunction with its barcode scan to ensure minimal errors.

Integration with Shipping

When the labeling cycle is complete, an exit conveyor transfers the finished package out of the Auto-Mailer. This presents ready-to-ship, custom-sized mail packages that are then directed to the correct shipping carrier using the system's fully-integrated multi-carrier shipping software.

Sealed and labeled packages exiting the system, ready for shipping.

The system’s in-line scale and proprietary dimensioning system record the dimensional weight of the package. This information is forwarded to the shipping carrier, which sends back a shipping label. This label is applied and printed, leaving the package ready to be sorted to the appropriate dock door.

Flexibility and Scalability

The advanced technology consolidates several end-of-line fulfillment processes into a single system and features detection, shrink wrapping, precisely-sized polybags and label application and printing, this system improves throughput and minimizes shipping mistakes.

Texwrap Model 3322 ePack Auto-Mailer

Capable of handling seasonal spikes in fulfillment while at the same time providing novel levels of product tracking throughout the end-of-line process, the system is geared to scale upwards with company growth. It can pack and label up to 20 packages per minute, while generating significant savings on packing material costs. It can also handle a wide range of package sizes, and its highly accurate dimensional scanning system provides the right-sized mailer for every product.

These latest models of automated fulfillment systems streamline the entire operational workflow, which translates to substantial ROI for e-commerce companies, large and small.

Illustration by sorbetto / DigitalVision Vectors via Getty Images. Photos courtesy of Texwrap Packaging Systems.

August 2021 // flexpackmag.com