The Critical Role of Labels

Victor Gomez, director of Industrial Label Products at Epson America, Inc., shares his thoughts on the supply chain and where label technology is headed.

The Critical Role of Labels

Victor Gomez, director of Industrial Label Products at Epson America, Inc., shares his thoughts on the supply chain and where label technology is headed.

Supply Chain

By far and away, the most topical subject of the moment is the reliability of the supply chain. That is a concern in many — if not most — business segments, but it’s felt keenly by label and packaging converters because labels are a critical component of any product. Without a label, a product doesn’t ship. And beyond products themselves, labels are used in logistics, warehousing and many other segments that directly affect our daily lives.

Label constructions marry disparate elements: substrate, coatings, liners, laminates, presses, finishers and — of course — ink. Most of these are sourced from specialized individual suppliers and must be coordinated to arrive on time, every time, to produce a label construction that fits the specifications of every job.

The global disruptions experienced since the start of the pandemic have upset some of the components of that supply chain. Converters have seen delivery delays lengthen with some of their converter suppliers, probably due to capacity constraints amid the surge in demand, raw material scarcity or logistical problems. An adaptation in the response to supply disruptions — including unmet deadlines that can be costly or represent missed opportunities — has been to turn to trusted, reliable suppliers.

The Epson SurePress L-6534VW UV Digital Label Press

Epson has redundancy in its ink supply chain — which doesn’t eliminate the challenges posed by the current environment — but it does help manage through these shocks. For example, ink for Epson SurePress color label presses is manufactured in any of half a dozen factories in different countries. The international nature of Epson’s business also means we saw the crisis build from its early stages last year, which prepared the company for when it reached North America.

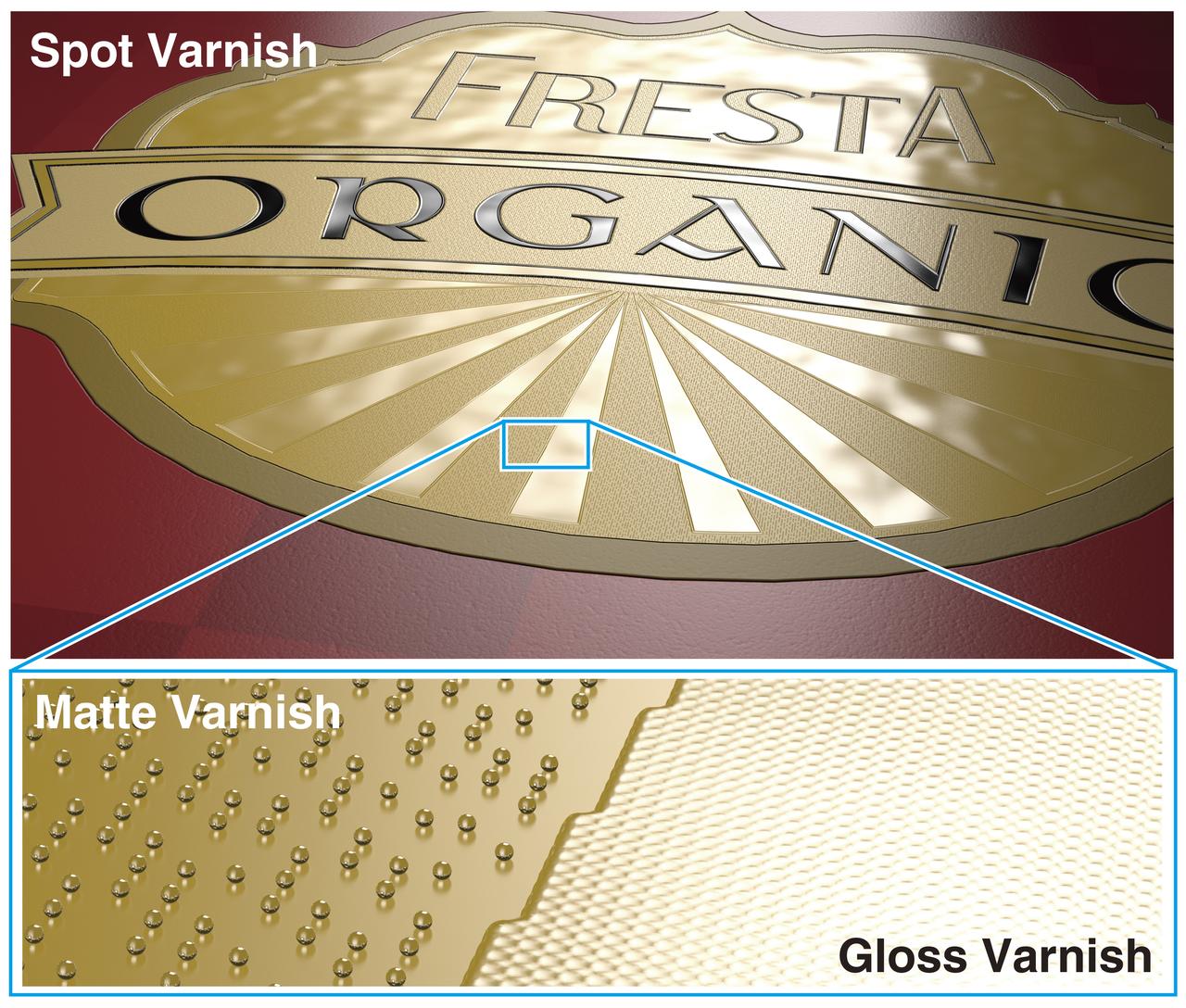

With digital varnish ink, both a gloss or matte finish spot varnish are available on the same label.

New Ink Sets

Epson continues to see development of different digital ink sets to fit specific applications. For example, new digital label inks are being offered for food packaging applications, such as Epson’s UV inks that conform with European FCM, EuPIA, Swiss Ordinance and FDA cGMP standards. Other developments address shrink applications, in-mold labels or tube applications.

This is a testament to the continuing penetration of digital inkjet — and especially of UV curable inkjet inks — into applications that have traditionally been addressable only with flexographic inks. Unlike most digital inkjet press manufacturers, Epson develops and manufactures its own inks, giving the company insight and economies of scale and technology to keep expanding its offerings.

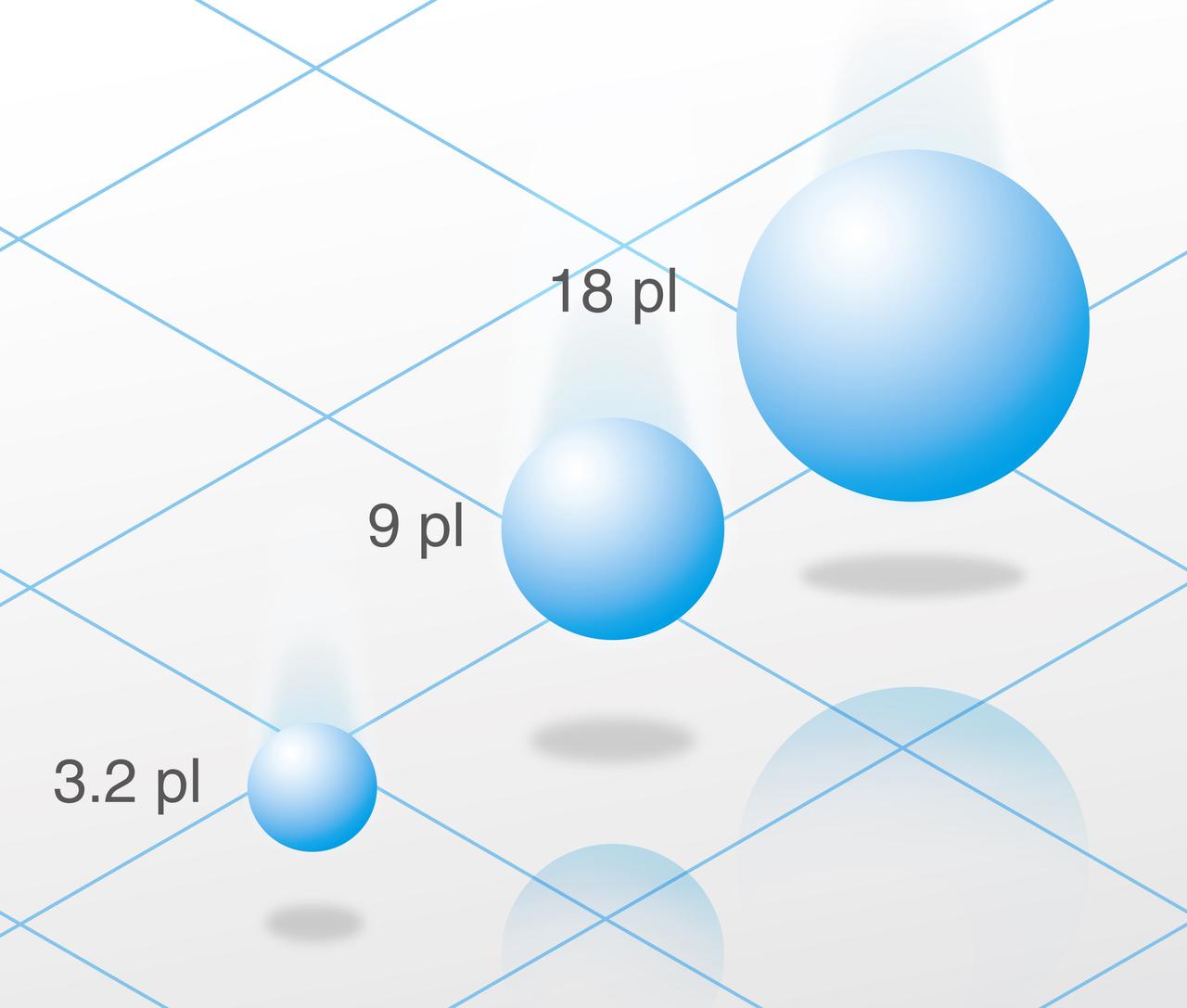

The Epson SurePress droplet size varies depending on the ink (color, white or digital varnish).

Some digital inkjet press manufacturers offer multiple ink sets from third-party suppliers, where each ink set is designed with a special ink characteristic, such as a high pigmented ink or a low migration ink. However, they can also be combined; a single ink set — for example, the Epson SurePress UV ink — can be an all-around solution, offering characteristics such as wide color gamut, high opacity, low-migration and high-adhesion.

Video by chekat / Creatas Video+ via Getty Images Plus. Photos courtesy of Epson America, Inc.

August 2021 // flexpackmag.com