Blending Accuracy and Efficiency:

Pouch Packaging of the Future

Why compromise on quality, flexibility and reputation when the future of pouch packaging is already here?

By Kevin Wells

As four in 10 Americans say that they are buying more pre-packaged foods, manufacturers are experiencing never-before-seen opportunities during the COVID-19 pandemic and need to act quickly: Consumers are expecting more variety and excitement in their foods while at home and cooking more often. The current crisis has also increased focus on healthy lifestyles, encouraging consumers to keep nutraceuticals and over-the-counter pharmaceuticals on hand.

Complex Products Require Optimized Packaging Processes

Not only do manufacturers need to offer and efficiently pack a wider range of SKUs more quickly — regardless if consumer packaged goods (CPGs) are working with co-packers or investing in their own packaging equipment — but they also need to ensure that they are delivering a high-quality, reliable product that protects consumer health and brand reputation. These requirements are particularly important for dry goods packed in a pouch format, in which inconsistencies are often noticeable for the customer or can in some cases have severe consequences.

Pouched pharmaceutical products that mix active ingredients with carrier elements, for example, need to be packaged with particular care. As each sachet is loaded with product on the manufacturing line, it is imperative that the filling equipment doses all ingredients correctly and uniformly to avoid too weak or too heavy drug levels. While not potentially life threatening, food products also contain their own risks around inconsistent dosage. Brands that miss the mark for consistency across one sachet to the next may be subject to consumer dissatisfaction and distrust.

Despite these challenges, pouch products have often traditionally used a pre-mixed filling method, in which batches of ingredients are combined into one standing mixture prior to moving into the pouch. While this may minimize the number of entry points of product and pulls from one joint source, the approach creates numerous opportunities for inconsistencies and inefficiencies.

With over-the-counter pharmaceutical formulations, for example, the pouch contains a sugar mixture with a very small dose of an active drug ingredient — granules that are difficult to control and that could become lost in pre-mixed batches placed into large hoppers. This is also true for certain food applications. For instance, the differing weights of ingredients in a pre-mixed batch of oatmeal (i.e. nuts or dried fruits) can cause some pieces to float near the top of batches while others settle near the bottom, influencing the way the product filters down and disperses into each individual sachet. The potential result is a medicinal tea that is missing enough of the active drug to help alleviate symptoms or an oatmeal pouch that feels stingy on advertised toppings.

ADVERTISEMENT

A Better Way to Pack

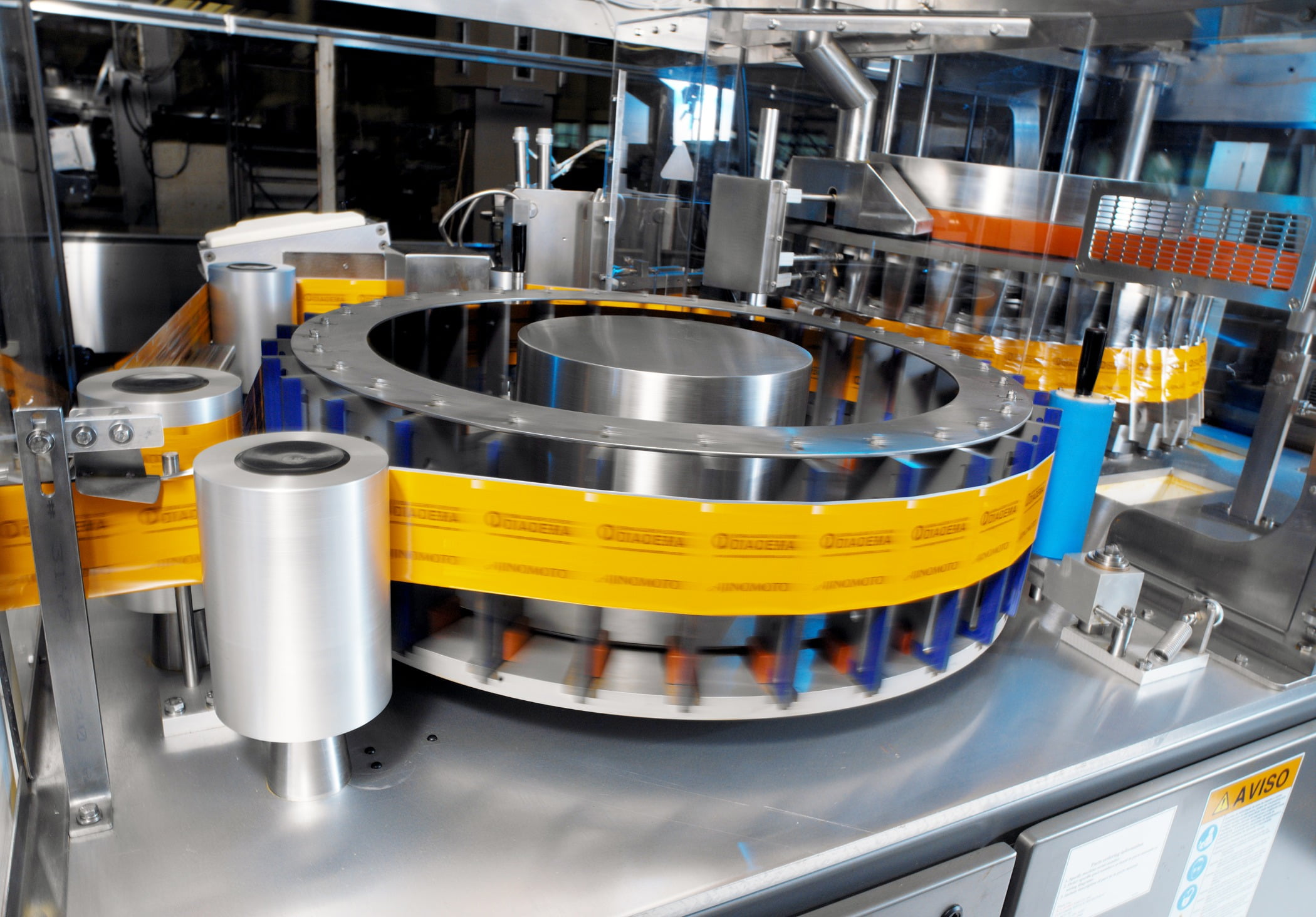

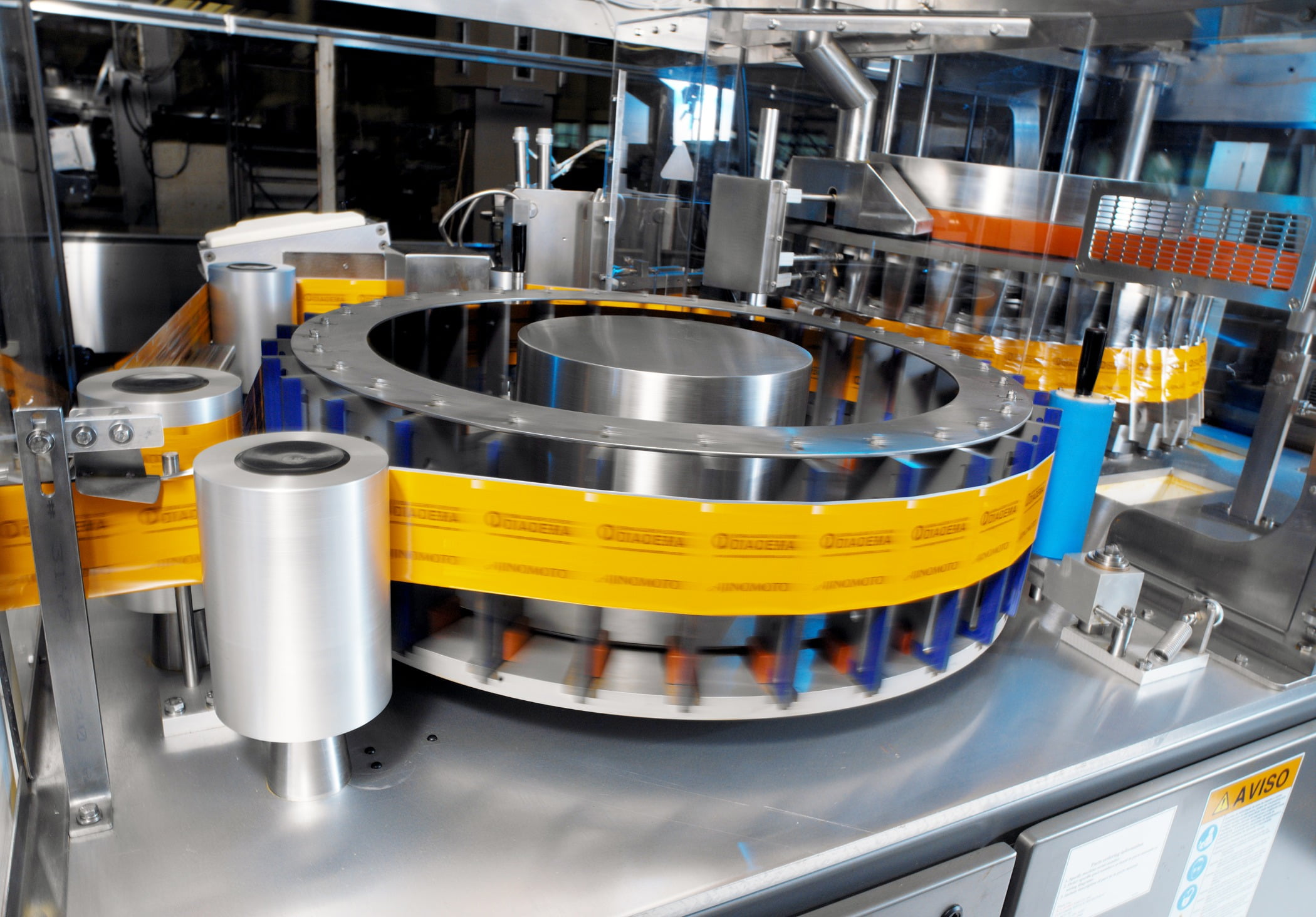

Inconsistencies in the final product come with a plethora of risks, ranging from health risks for consumers due to an allergy or wrongly dosed medicine to reputational risks for food brands if consumers share their unhappiness or poor experience with family, friends or on social media. As a result, leading packaging engineers developed a new generation of high-speed, horizontal form-fill-seal (HFFS) machines for a variety of pouch styles that offer a wide range of feeding systems for individual or multi-component blends.

Equipped with an online blending feature that combines up to seven product feeds and doses the different ingredients directly into the filler, the machinery promotes greater control over individual ingredient dosage and eliminates the need for pre-mixed batches — a less-consistent, time-consuming process. The result is greater operational efficiency and a more reliable product for consumers.

For greater protection, pouch packaging equipment must also be designed with hygiene in mind.

Cleanability allows for greater versatility when machinery can facilitate safer, quicker changeovers and easy sanitization processes between product types. With this in mind, the latest packaging solutions allow changeover to occur at almost just the touch of a button: Any combination of feeders can be set up via an easy-to-use human-machine interface (HMI).

These more advanced systems also provide feedback on ingredient density and weight, determining flow rate as the belts transporting product continuously weigh and adapt distribution, resulting in less downtime and less product waste over time. In addition, the accumulator further allows the machine to continue running after minor stops, improving overall equipment effectiveness (OEE) along the manufacturing line. Ultimately, these design elements save considerable costs without compromising on safety or packaging speed. In fact, the system’s unique integration with a cartoner can approximately pack 500-600 boxes per minute in a single-pouch, multiple-ingredient configuration.

Equipped with an online blending feature that combines up to seven product feeds and doses the different ingredients directly into the filler, the machinery promotes greater control over individual ingredient dosage and eliminates the need for pre-mixed batches — a less-consistent, time-consuming process.

Aligned to Changing Supply Chains

Removing the need to use the pre-mixed batch method also means manufacturers can finally package goods on demand, rather than having to mix major amounts of product in advance and face various logistical issues such as delivery of product from off-site locations or concerns of product shelf life throughout storage. The more simplified supply chain also allows for critical flexibility around limited-edition and seasonal offerings that place pressure on CPGs to debut new products quickly. In this sense, online blending allows manufacturers to greatly enhance speed to market, helping to build and diversify product portfolios.

In addition, manufacturers can finally enable constant flow with the latest filling technologies, packing and containing ingredients of varied shapes, sizes and textures without disturbing the seal and enabling a solid, safe close of the pouch each time. Avoiding failed or inconsistent seals helps to mitigate risk of food quality issues and associated downtime. To streamline the packaging process even further, improving count flexibility is key.

New innovative knife features unique to more advanced machinery can allow the manufacturer to switch between multiple counts, ranging from a six-count option up to a 12-count option, at the push of a button. These adjustments can be implemented without physical knife changes at high speeds — a benefit for greater output and operational safety.

Increased flexibility is a no-brainer for countless food applications. Manufacturers can, for example, now pack a larger variety of side dishes. Think gravy, rice and beans with different spices, or even cereals — ensuring consumers are repeatedly satisfied with the trusted consistency of their products. With the latest generation of machines, such as the Pouch King, and by working with the right team of design and manufacturing packaging machinery experts, manufacturers can better ensure that production line setup enables rather than restrains output.

The latest packaging machinery optimized for both quality and quantity is enabled by online blending, easy changeovers and count changes at the touch of a button. At the end of the day, brands need to ask themselves: Why compromise on quality, flexibility and reputation when the future of pouch packaging is already here?

Photos courtesy of R.A. Jones

July 2021 // flexpackmag.com