Introducing the First Dual-sided Pouch

In a continuously evolving and competitive marketplace, packaging plays a key role in determining a brand’s success. Flexible pouch packaging has been leading the way in transforming common CPGs for more than a decade. The latest game changer —the first dual-sided pouch — is repackaging a classic combination: PB&J

By Kristin Joker

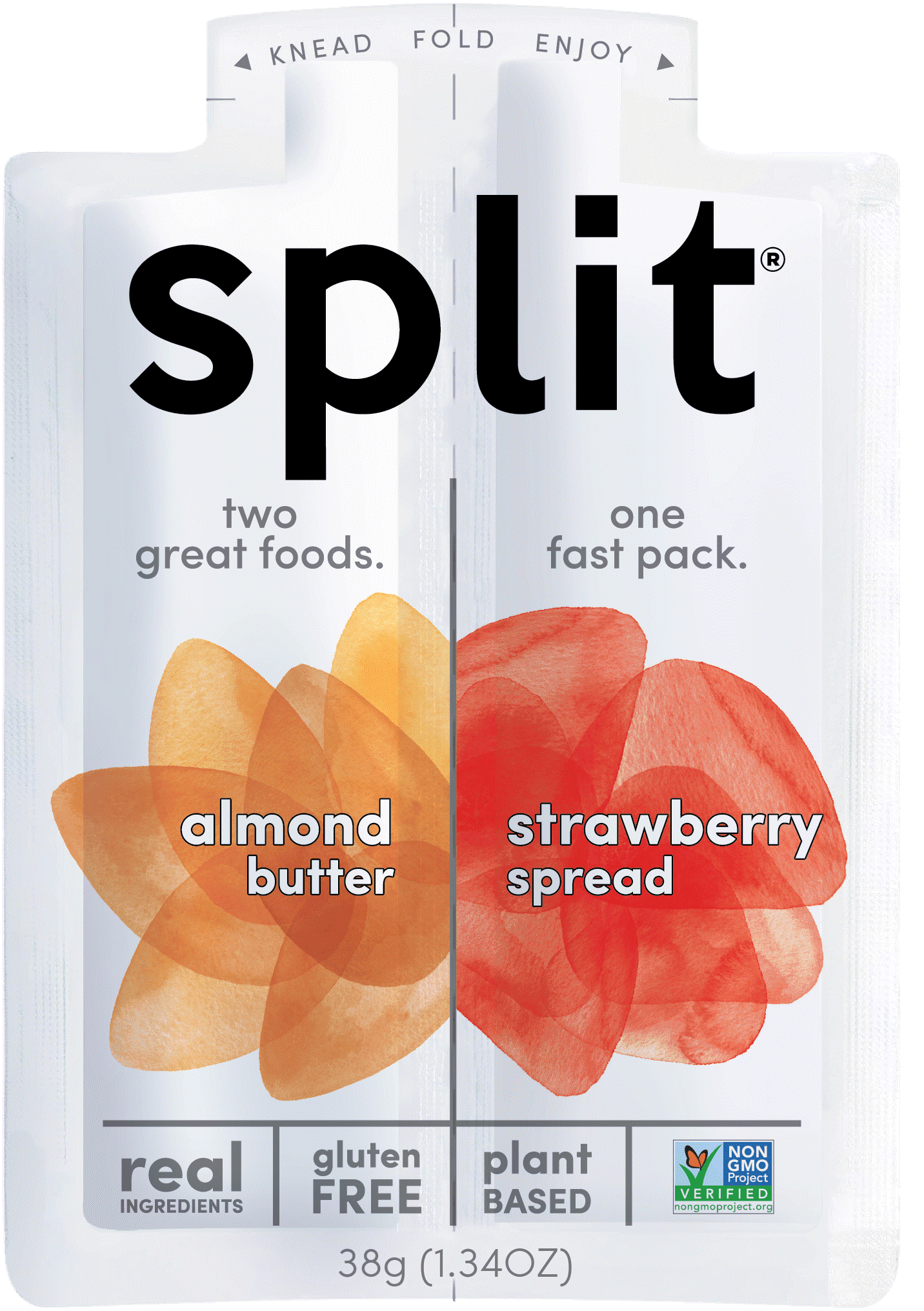

Split Nutrition is a classic example of a product that is greater than the sum of its parts. Since the invention of sliced bread, people have been pairing peanut butter and jelly. Thanks to the innovation of the first dual-sided pouch, we no longer need the knife, or the bread for that matter. It took the combination of passionate brand owners and a dedicated vender to bring the inventive idea to market.

A Twist on a Classic

Before Jeff Mahin became the accomplished chef and restaurateur he is today, he was a typical kid fueled by Pop Tarts and peanut butter and jelly sandwiches. That changed when he trained to become a chef. As his knowledge of quality ingredients deepened, a passion for health and wellness began to grow. As an avid cyclist, Mahin was always looking for a nutritious snack that was portable and easy to eat. It also needed to be leak proof and not require refrigeration. He sought assistance from Dr. Phil Goglia, a nutritionist who advises professional athletes. Together they discovered a hole in the market. Despite the popularity of peanut butter and jelly, nobody was making a convenient way to eat it on the go.

Because PB&J is a healthy snack at its core, they could easily tweak the ingredients to include various nut butters. With that, the pair set out to reinvent how America eats peanut butter and jelly.

Split Nutrition delivers a classic combination with less mess.

The Jam

Jessica Quon is the co-owner of The Jam Stand, a brand known for taking unusual flavor combinations (cherry, chipotle and cocoa) and turning it into cult favorites. Quon and her best friend, Sabrina Valle founded The Jam Stand in 2012. In a few years, the pair quickly grew the brand from farmer’s market to national (brick and mortar) distribution. Quon even appeared on season one of CNBC’s Billion Dollar Buyer where she and Valle successfully pitched Tillman Fertitta, owner of Landry’s and the Houston Rockets, to carry their products. They met and partnered, with Quon currently overseeing Spilt Nutrition’s operations, and the rest is packaging history.

The Package is the Twist

The package concept began the way many breakthrough ideas do — a sketch on a napkin. “There were several iterations, and some of the first ideas were too difficult to manufacture or were too impractical," says Mahin. Once he had a clear idea of the package shape, he sought the right partner. Finding a full-service flexible packaging provider that could produce a pouch with the uncommon feature of a fold with a tear-off tab was not easy, but Prairie State Group (PSG) fit the bill. The flexible packaging company and printed film supplier provided one-on-one guidance for Split Nutrition on its proprietary snack packaging.

The process from concept to consumer went smoothly because Prairie State Group keeps in constant contact with its clients. “Graham [Redding, president of PSG] was extremely hands on. And since we came in not knowing a lot about the packaging world, he took the time to help us find the right foils and pack details that would work to make the best product possible that aligned with our vision,” Mahin says. A key element was that the pouch needed to be strong enough to handle being used on-the-go and during athletic events.

The dual-chambered single-serve pouch is ideal for food pairing.

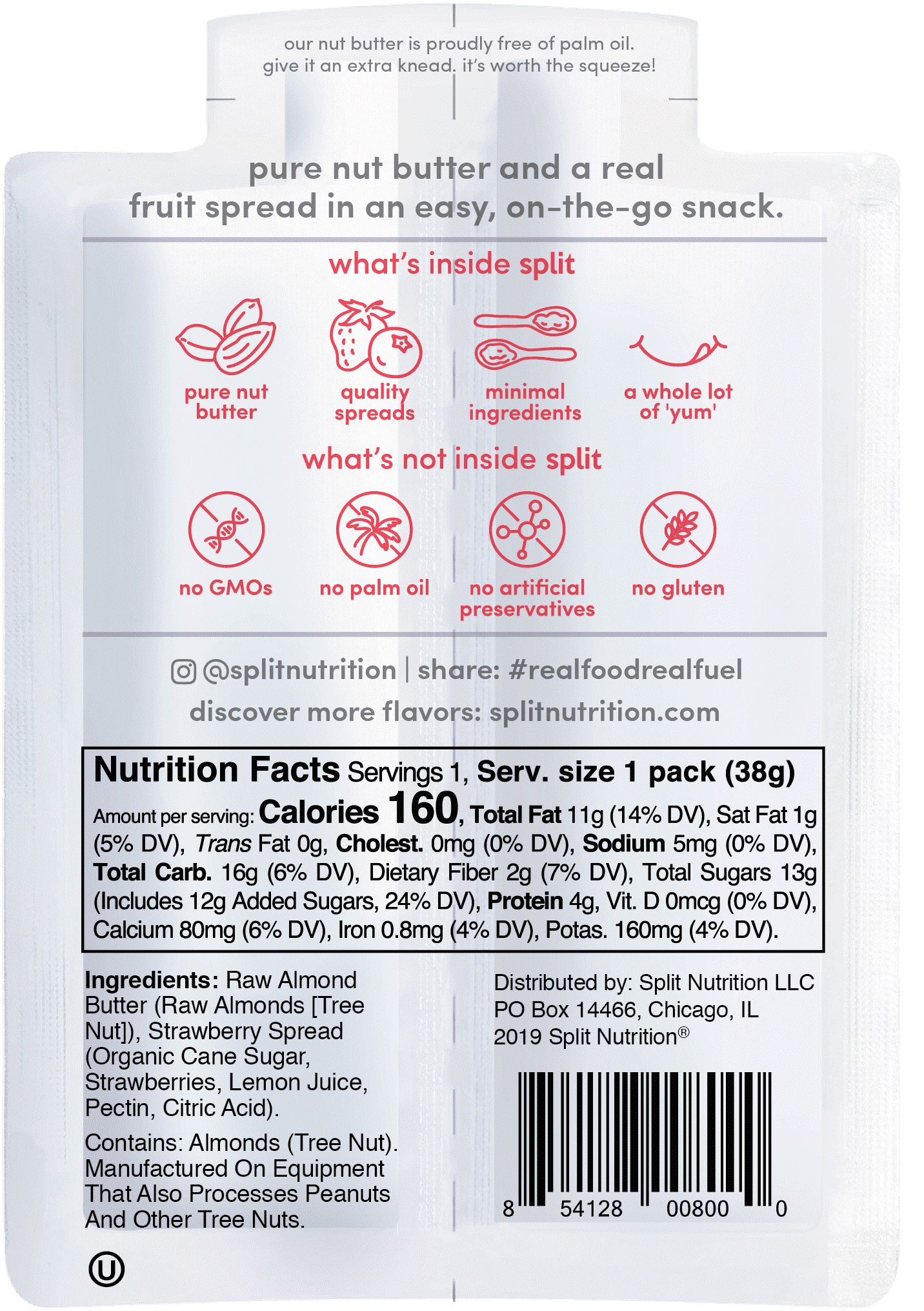

The dual-chambered option is ideal for food pairing — PB & J being the most obvious — but Reed points out a challenge, “Split’s dual-chambered single-serve package requires special filling equipment and very specific materials to bring it to life. This multi- structure, high-barrier film structure has to be stiff, stable, while offering a good customer experience, precision tearing and durability. Most films do not check all those boxes, but what PSG engineered does.”

The challenge did not stop there. “Finding a co-packer that could handle the butters and the jelly spreads in the same room does not leave a lot of options. Allergens are a big concern. Finding a filling machine that can produce a die-cut allowing for the proper 'tear strip' neck eliminates a number of standard possibilities,” Reed explains. This required a machine that offers stability with the material. (i.e. tension, sealing, etc.), the special tooling and die cutting to create the neck (the dispensing area), the corners, and the center crease.

Recipe for Success

Although the packaging is a point of difference for Split Nutrition, what is in the package is equally important. Split Nutrition exemplifies precisely what the Mintel 2021 Global Food and Drink Trends reports advises, “In 2021 and beyond, food and drink companies will create mental and emotional wellbeing solutions, deliver on new value needs and use brands to celebrate people’s identities.”

Recognizing the opportunity to leverage the dual-chamber packaging, the team at Split Nutrition has recently begun providing private label services. “Our private label efforts will continue to be awesome combinations to CPG markets including condiment, beauty products, cocktails and more," Mahin says.

Consumers want healthy and convenient snacks.

Elements of a Successful Pouch Product

Safe and saves time: Single-serve pouches limit the spread of viruses and bacteria, particularly in socially-distanced, outdoor group settings. Joggers, cyclists, hikers and more can enjoy on-the-go snack breaks without the risk that larger, shareable snack packaging could present during the pandemic. Also, PSG is a Safe Quality Food (SQF) certified plant and has been for nearly 10 years.

Simple and satisfying: Mintel’s report also explains, when it comes to value, pandemic-shocked consumers are seeking a return to what is essential. Consumers are now focused on minimal consumption and getting the best returns from their purchases. As markets reopen after COVID-19 restrictions, the pace of life will get busier — requiring more convenience options. Consumers will expect time-saving, hygienic and adventurous convenience food, drink and foodservice.

The best part? Less peanut butter covered spoons and butter knives to rinse (scrape) off.

Parents rejoice!

SIDEBAR

Flexible Packaging by the Numbers

Flexible packaging represents approximately 19% of the total $177 billion U.S. packaging industry and is the second-largest packaging segment behind corrugated paper and just ahead of bottles and miscellaneous rigid plastics packaging.

Flexible packaging used for food (including both retail and institutional) is estimated at $17.6 billion (52%) for 2019, higher than the estimate of $15 billion for 2018. However, this year’s survey provided additional detail/estimates for beverage $3.4 billion, pet food $1.3 billion, personal care $2 billion and tobacco $0.3 billion (FPA).

Flexible packaging’s solid long-term strength coupled with flexibles’ ability to replace other packaging formats has resulted in the growth of flexible as a percent of total U.S. packaging, increasing from 17% in 2000 to the current level of 19% in 2019.

Cover and feature video by yasinemir / Creatas Video via Getty Images. All images courtesy of Split Nutrition.

June 2021 // flexpackmag.com