Can Plasma Surface Treatment Deliver Sustainable Solutions and Reduce Cost?

The printing and converting industry is moving quickly to develop more recyclable material to help consumer packaged goods companies meet fast-approaching sustainability goals. And new plasma treatment research is showing opportunities for converters and extruders to reduce solvents and increase recyclable film material.

By Grant Gerke

Incrementalism may be gone in the flexible packaging industry, as film suppliers and consumer packaged good (CPG) companies race to find sustainable solutions in both upstream and downstream areas. Downstream areas include material recovery facilities (MRFs) and many of those operations are making advances in the U.S., and European mandates have been ramping for the last five years.

Upstream trends in the industry include a focus on mono-material film development by packaging film suppliers that feed cleaner material to MRFs in the future — see Südpack’s goals for 2025. A second trend is reducing overall solvent use by film extruders and converters when it comes to increasing surface energy for plastic substrates.

One company aiding in these developments is Vetaphone, a supplier of plasma and corona machinery. The company recently presented a white paper on modern plasma technology titled, “Specialized Plasma Technology Improves Adhesion Of Water-Based Primers, Inks, and Coatings.” Vetaphone also presented accompanying research on atmospheric pressure plasma technology in a recent webinar in December 2020.

ADVERTISEMENT

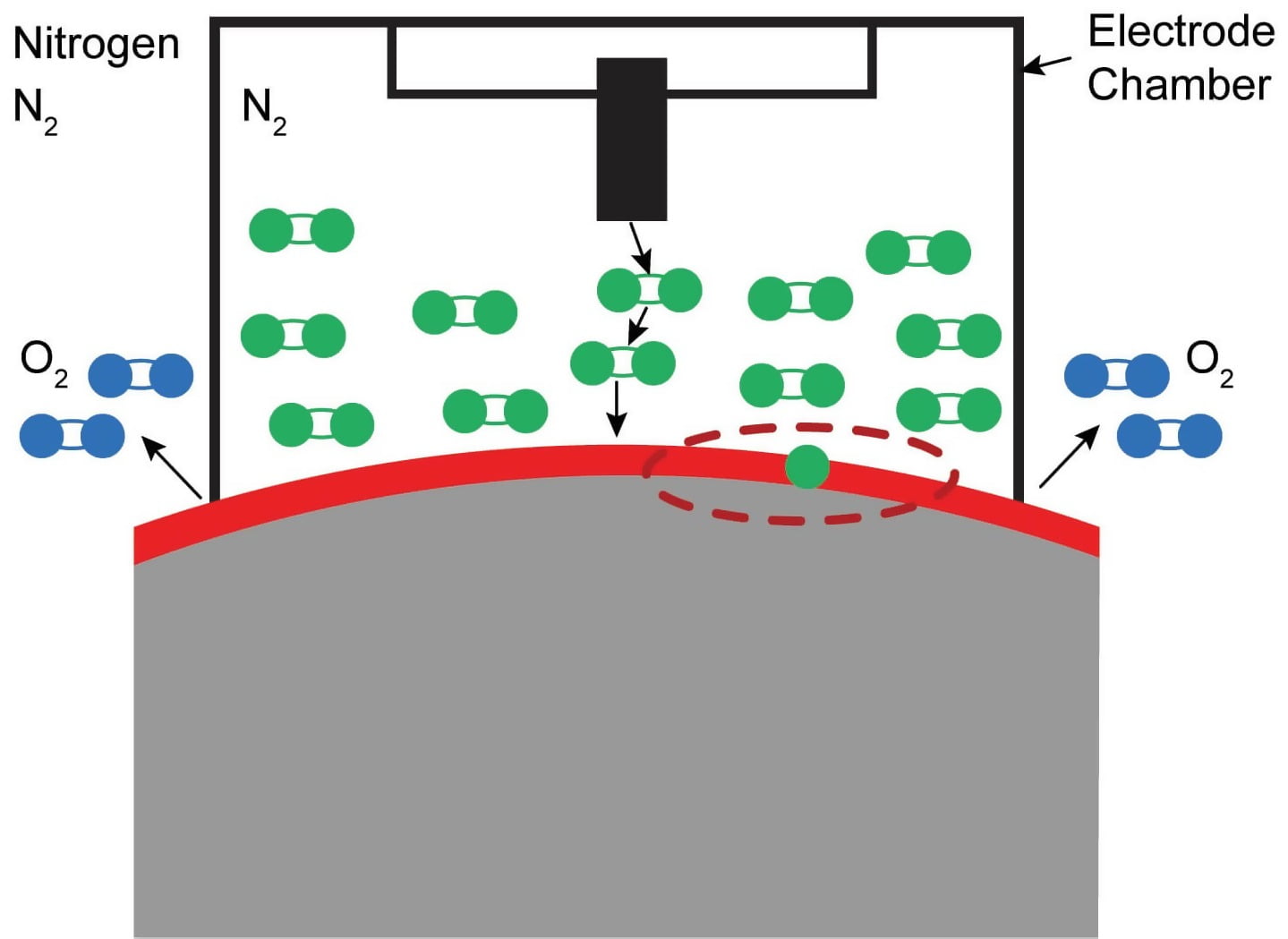

The white paper, authored by Kim Bredgaard, project sales manager, and Kevin McKell, vice president of technical sales at Vetaphone AS, discusses plasma technology and how it uses reactive nitrogen to increase a film’s surface energy, such as biaxially oriented polypropylene (BOPP). Nitrogen creates amines, amides and imides on the surface and replaces carbonyl groups.

A big takeaway from the company’s recent atmospheric pressure plasma research is that it substantially increases surface energy — or tension — for polymer substrates, and it provides the ability to both raise the dyne reading to a higher level than other treatment methods and sustain that raised level for longer periods.

In contrast, corona treatment of BOPP films will achieve a maximum surface tension value of approximately 46 dyne/cm, per Vetaphone’s findings. Also, the paper cites that BOPP film treated by corona will return to its native level of 32 dyne/cm after a certain amount of time. Film manufacturers also use additives to ensure better performance of substrates downstream in the production process, which include plasticizers, anti-static agents, heat stabilizers, UV and light stabilizers, and antioxidants.

The major takeaway of Vetaphone’s plasma technology research is that the “aging process with a polymer film is slowed down or even stops entirely with plasma.” The white paper cites “plasma is not a new technology, but the latest developments offer a higher level of sustainable surface tension that takes it beyond the capability of corona treatment.”

Vetaphone’s research shows increased power to polymer film with plasma treatment, and more radicals of nitrogen-related bondings are formed and are less permeable to additives.

Image courtesy of Vetaphone

So what is the explanation behind these new findings? The new developments show “that as increased power is applied to polymer film with plasma treatment, more radicals of nitrogen-related bondings are formed and are less permeable to additives.”

“We have been researching vacuum plasma and we’ve been taking the best processes from the vacuum and bringing it to atmospheric pressure,” says Bredgaard in the recent webinar. “The atmospheric pressure plasma should make it possible to do plasma inline.”

The company offers two levels of power with its plasma technology: medium and high. The medium-power plasma treatment erodes at a similar pace as corona, but the aging stops at a higher level of 46 dyne/cm and stabilizes. The high-power plasma application, which is offered as added value to those who need to retain a higher dyne level for longer, for example 60 dyne/cm for BOPP, is recommended by Vetaphone as an off-line application.

This research suggests converters can reduce solvent-based primers and coatings, and even move to water-based inks or adhesives in the printing process to help converters and CPGs move closer to sustainability goals. The recent webinar revealed that printing applications using water-based ink need a 46 to 48 dyne/cm level, while coating comes in at 44 to 54 and lamination ranges from 46 to 56 dyne/cm.

Besides BOPP, other film materials have been able to achieve higher surface energy levels with plasma, such as polypropylene (PP), oriented polypropylene (OPP), polyvinyl chloride (PVC), polyethylene terephthalate (PET) and polyvinyl chloride (PVDC).

In June 2020, Vetaphone opened a test lab in Kolding, Denmark for printers, converters, laminators and extruders to do extensive research and development with corona and plasma technology.

Image courtesy of Vetaphone

Vetaphone’s New Test Lab

In June 2020, Vetaphone opened a test lab in Kolding, Denmark for printers, converters, laminators and extruders to do extensive research and development (R&D) with corona and plasma technology. During the webinar, Bredgaard cited a customer that wanted to move away from corona-treated substrates with additional solvent-based primers and move to water-based primers instead.

“We tested plasma treatment technology with the different water-based primer candidates and found a combination that worked well for the customers’ applications,” says Bredgaard. The return on investment for this new approach was 31 months and provided a “greener” profile and cost reduction for the Vetaphone customer. Another customer wanted to move to PP film material to reduce costs, and plasma treatment made this possible with just a 23-month return on investment.

New sustainable-based solutions are starting to shape and gain momentum in the converting and flexible packaging world. As companies go down this road, they may also be finding cost reductions are part and parcel.

Video by saicle / Creatas Video+ via Getty Images Plus

March 2021 // flexpackmag.com