One Year Later: How the COVID-19 Pandemic Continues to Drive Long-term Shifts in Packaging Strategies

Several shifts perpetuated by the pandemic now represent long-term changes that will ultimately serve to benefit the manufacturing and packaging industries.

By Bharani Bobba

BHARANI BOBBA

One Year Later: How the COVID-19 Pandemic Continues to Drive Long-term Shifts in Packaging Strategies

Several shifts perpetuated by the pandemic now represent long-term changes that will ultimately serve to benefit the manufacturing and packaging industries.

By Bharani Bobba

2020 was a year unlike any other in recent memory: The COVID-19 pandemic caused a nationwide shift in all manners of daily life. In the manufacturing realm, due to the influx of people choosing to stay at home and do more of their shopping virtually, companies needed to adapt quickly to make flexible, efficient manufacturing and packaging a key part of the strategies to meet increased demand.

While the shifts we witnessed in 2020 may have seemed sudden, several shifts perpetuated by the pandemic now represent long-term changes that will ultimately serve to benefit the manufacturing and packaging industries on a number of levels.

Change creates opportunity, and here are three opportunities we foresee here in 2021 and beyond in our post-pandemic world.

FillPak paper packaging material provides an effective way to fill empty spaces in a box, preventing products from shifting around during transit.

Consumers and Companies Alike Will Care More About the Future of our Planet

In January of this year, Ranpak issued a survey in conjunction with Harris research which found that more than three quarters of Americans (78%) wish more brands used paper packaging (e.g. cardboard boxes, paper mailers, paper fill inside the package) instead of plastic packaging (e.g. plastic envelope, plastic pillows inside the box, bubble wrap).

What’s more, over two thirds of Americans, or 68%, would be more likely to purchase from online retailers and brands that offer plastic-free packaging choices at checkout than online retailers who do not.

Consumers are seeking products that demonstrate sustainability throughout the entire lifecycle, and that includes secondary packaging, which protects items inside of the box. This demand highlights a fantastic opportunity to leverage more recyclable and sustainable materials to combat the rising issue of plastic waste that has been brought to the surface in the COVID environment. In 2015, the U.S. alone generated 6.3 billion metric tons of plastic waste, of which plastic packaging alone accounted for 47%. Only about 9% was recycled and 12% incinerated, with 79% left to occupy landfills or pollute the natural environment for hundreds of years — with issues like this presiding at the crossroads of environmental and consumer concerns, companies are in a great position to increase their efforts toward addressing plastic waste and championing sustainable solutions.

Take for example the advent of paper packaging — it is one of the most sustainable products as it’s biodegradable and made from renewable resources.

Putting aside these environmental and sustainability benefits, paper is also good for the bottom line — it outperforms many in-the-box product alternatives, especially when considering indirect costs such as handling and storage, employee safety, machine downtime and facility cleanup.

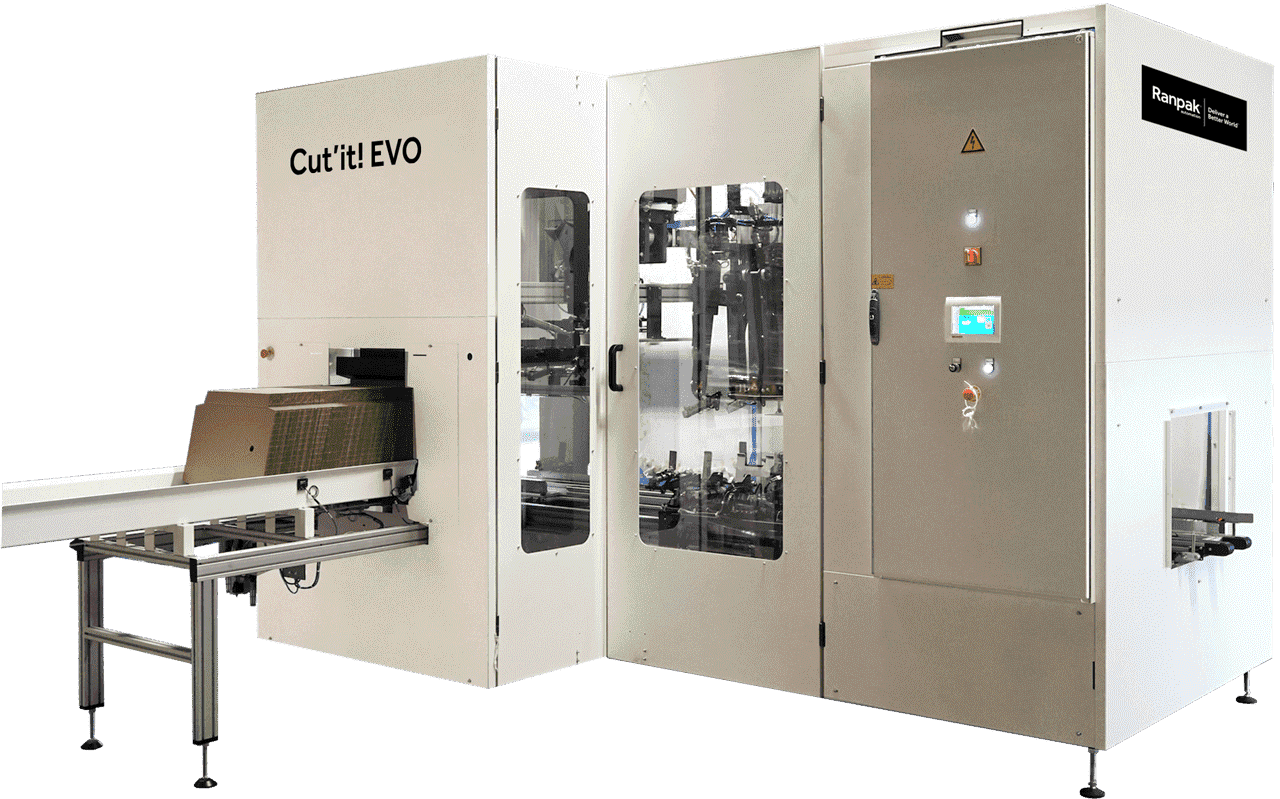

The EVO Cut’it! automated in-line packing machine reduces voids in parcels before shipping, cutting down on shipping costs.

Advances in Automation Will Help Your Employees Work Smarter, Not Harder

According to our recent survey, e-commerce doesn’t seem to be dying down in 2021: 67% of Americans plan to do more online shopping (e.g. household items, groceries, gifts) in 2021 than in 2020. Increased e-commerce means increased shipping and, in turn, increased demands on warehouses as they prepare these packages for shipment. This means that automation will be increasingly important.

While there’s a misconception that automation may be used to simply "phase out" traditional labor, the reality is that automation and human labor will coalesce in the post-pandemic world and work hand-in-hand. In the next wave of globalization, developing highly skilled workers to complement forthcoming digital technologies and innovations will be paramount.

Automation technology can amplify the speed at which employees can package goods for shipment, freeing them up to work more effectively on other labor-intensive activities in the warehouse. It's an ideal example of how a workforce trained in automation can maximize output.

Automation serves a wide variety of benefits outside of just increasing efficiency and output. Automation tools can help you analyze and improve consumables costs, reduce waste, quickly adjust for seasonal volume peaks, optimize freight and provide many other contributions to overall costs and usage — all bottom-line bolstering moves. Automation can also ultimately reduce warehouse space. Since the pandemic, there has been a scramble amongst retailers to either upgrade warehouses or do more with the same amount of space. The packaging process needs to be increasingly quick, ergonomic and cost efficient, as warehouse space is becoming rarer and more expensive.

The Geami WrapPak Manual converter expands die-cut kraft paper into a 3D honeycomb structure.

Jobs in Manufacturing and Packaging Jobs Will be Increasingly Important

While things may seem uncertain, packaging and warehouses are now more important than ever thanks to the accelerated growth of e-commerce, meaning that jobs are becoming more widely available. According to the Bureau of Labor Statistics, warehouse employment has surpassed its pre-pandemic level to reach the highest level ever recorded with 1.25 million workers in the warehouse and storage sector in September of 2020. Yet, even since entering 2021, we are still facing a labor shortage. Now is the time to make sure careers in manufacturing are lucrative, appreciated and rewarding.

It’s challenging enough to get new manufacturing talent through the door — it’s another thing entirely to give them meaningful benefits to ensure they remain, grow and contribute meaningfully to the company in the future, so we must shift our mindset around manufacturing careers.

Employees are loyal to careers, not jobs. According to a study by Mercer, 78% of employees would stay with their current employer if they knew they had a career path instead of just a job. Employers in the manufacturing and packaging industries should find ways to make jobs in their warehouses more rewarding.

The new PadPak Guardian offers the latest technology, delivering the highest yield per foot at the fastest speed, reducing material usage time and labor.

Considering that this generation of manufacturing employees will be some of the first to work truly hand-in-hand with automated machines, genuine recognition of employees will be instrumental to instill purpose, confidence and — above all else — a sense of meaningful fulfillment in a job that so many around the nation rely upon for their wants and needs.

Employers can also provide tuition reimbursement for vocational training, continued education and paths to leadership. Doing this allows employers to truly put their money where their mouth is by investing not in paychecks, but in the continual growth and professionalism of staff. With these opportunities available to employees, it is much more difficult for workers to reach a point of stagnation, as they will be provided ongoing resources and chances to refine their trade and find greater fulfilment in what they do.

All images courtesy of Ranpak

May 2021 // flexpackmag.com