Advanced Software Adoption Accelerates for Printers and Converters

Printers and converters continue to add advanced software for prepress functions while also evaluating new platforms to optimize quality control during print runs and reduce overall ink consumption.

By Grant Gerke

Advanced software and integrated digital prepress platforms are helping printers optimize operations by automating processes, reducing ink consumption, enhancing inline print inspection and assimilate new technology applications, such as digital watermarking, into current workflows.

The idea of adding large automation solutions 20 years ago produced waves of anxiety for purchasing managers due to price, commitment and return-on-investment (ROI) unknowns. In today’s world, advanced software solutions for the printing and converting industry are still a sizable commitment, but upfront costs are lower and ROI is easier to understand due to data analytics.

One example of a new platform to optimize quality control resides at Unilever Dubai. This production facility specializes in shampoos and lotions —personal care products — and quality control analysts are responsible for the labels before being shipped to the packaging production lines. Prior to the addition of the inspection platform, all proofreading was done manually in the lab by two proofreaders. One challenge with the older process was the ability to spot errors on smaller fonts — printed in multiple foreign languages — and many QC analysts for Unilever were inspecting text that wasn’t their native language.

Unilever eventually turned to Montreal-based GlobalVision and its automated Print Inspection module for its digital quality control systems that offers a common platform between end users and printers. The common platform allows for Unilever’s analysts to inspect and compare original artwork and finished labels that came from the printers. The inspection module also compares the finished label samples on the packaging to the original digital files.

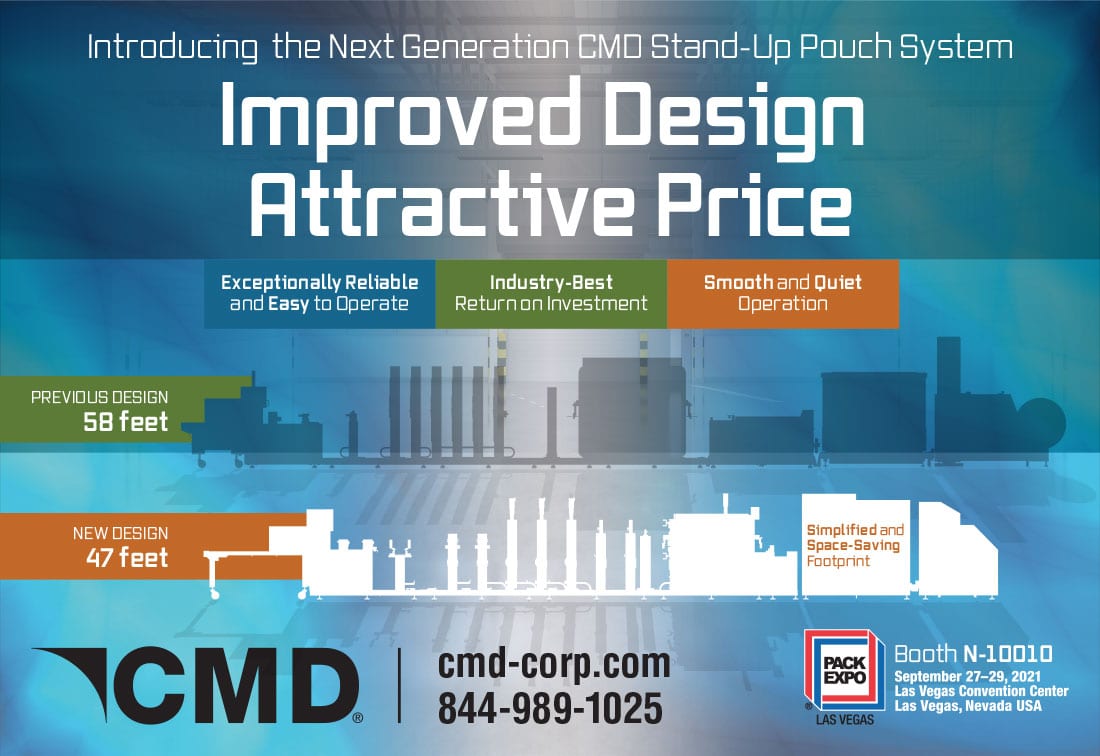

ADVERTISEMENT

Quality control inspections can reach up to 200 labels per week. “Overall, the team is able to save between 10 to 15 minutes per label when proofreading with the new automation inspection system,” says Imran Masood, quality specialist at Unilever, Dubai Personal Care Factory.

Another collaborative case study of a common enterprise platform searching for optimization is Finnish-based Wipak and its use of Esko Graphics and Global Vision’s platforms to assist in inspecting a variety of packaging jobs, including Digimarc’s “hidden code” technology. Wipak uses Digimarc’s technology and its hidden barcode technology for a range of customer applications that are centered around flexo, digital or gravure printing. Digimarc’s barcode technology can host multiple types of enterprise data, including serial data or production data that an enterprise can use to help optimize operations.

To find operational efficiencies, Wipak uses Global Vision’s automated print inspection software in pre-press to validate labels before print runs and also integrates a Digimarc plug-in within the platform to inspect the correct codes and provide a grade with this cutting-edge technology.

Once a grade is given and the inspection module approves the label, Wipak relies on Esko Grpahic’s AVT module to automate inline inspection of color, process control and quality during print runs.

“Our inline inspection system is checking for color shade, registration and anything else that can happen on a narrow or wide web reaching up to 8.5 ft wide,” says Guy Yogev, senior director of product marketing at ESKO. Line speeds can range from 980 to 1640 ft/min, and using the automated inline systems allows for Wipak to remove quality control checks during the production runs.

“Before, we would need time after a certain amount of feet that were printed and produced, and conduct a second quality control check,” says Florian Constabel, head of Digimarc at Wipak. “With the automated inline inspection, this provides a real opportunity to steer and monitor the performance of Digimarc barcodes throughout the complete production line.

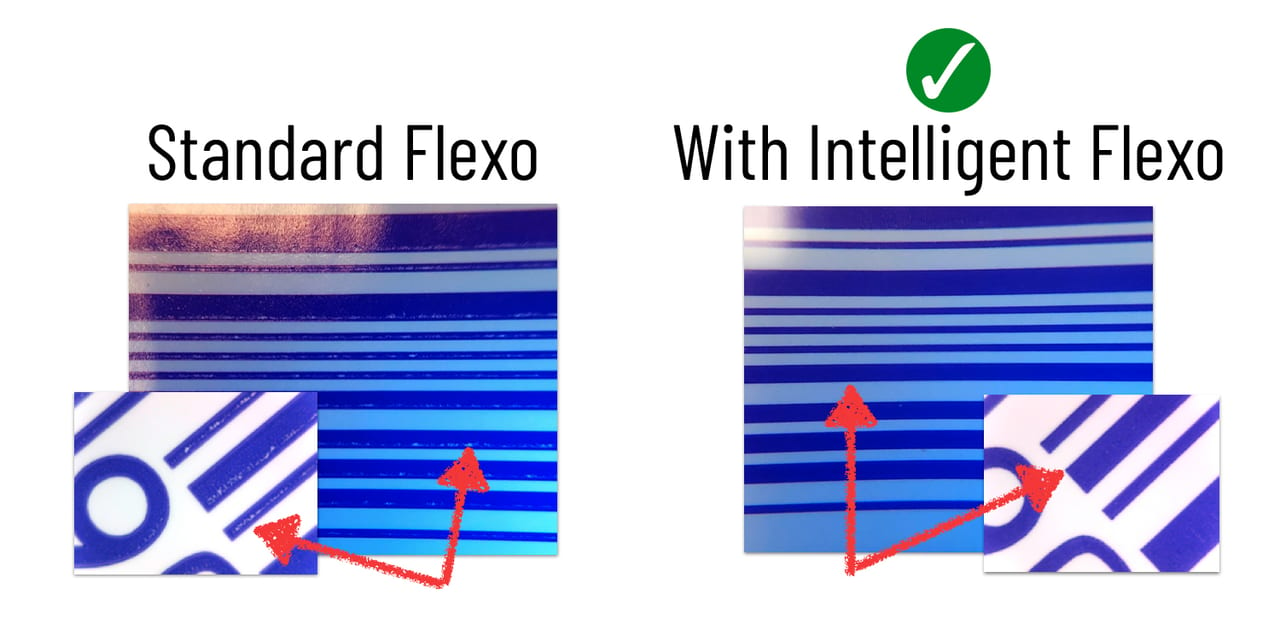

Intelligent Flexo (IFO) provides a software solution that adds microcell structures to screening dots and increases ink transfer from plate to substrates.

Courtesy of Steurs

Software Innovation Increases Print Quality

Steurs Graphic Solutions, Antwerp, Belgium, has been doing business since 1949 and offers prepress, packaging and publishing services while also emphasizing innovation throughout its company’s history. “Research and development (R&D) is critical to our philosophy,” says Tom De Bondt, CTO at Steurs. “To be taken seriously as a professional prepress partner, you must be able to innovate and develop tailor-made solutions to customers’ challenges.”

With this in mind, Steurs and HYBRID Software, Trevose, PA, are technology partners and offer Intelligent Flexo (IFO), an innovative process that provides a software solution to add microcell structures to screening dots and increase ink transfer from plate to substrates. The S-Dot technology — screening dots — “lowers ink consumption and increases print quality of flat tints, vignettes, barcodes and fine text,” according to Steurs.

At the start, Steurs focused IFO on corrugated paperboard applications and found great success due to the control of anilox-to-image carrier and image carrier-to-substrate. “We explored IFO plates in several markets, one of which was corrugated paper,” says De Bondt.

Steurs and HYBRID Software are technology partners and offer Intelligent Flexo (IFO) that provides a machine-independent software solution to add microcell structures to screening dots.

Courtesy of Steurs

IFO’s innovation is due to the software’s ability to automate the S-Dot technology process. “The application of the ‘S-Dot’ technology, without an automated platform, is very manual, '' says De Bondt. So, Fleurs turned to Hybrid Software and its Cloudflow automation software that offers file processing, asset management, soft proofing and workflow automation on its web-based platform.

“We didn’t have to change anything about the technology itself, but our added value was mainly in the development and parameterization of a tool that brings about a quality improvement for all possible flexo production machines and plates,” says Thomas Elton, production manager at Hybrid Software. “In addition, unique algorithms have also been developed to fully automate the manual steps that Steurs used to apply.”

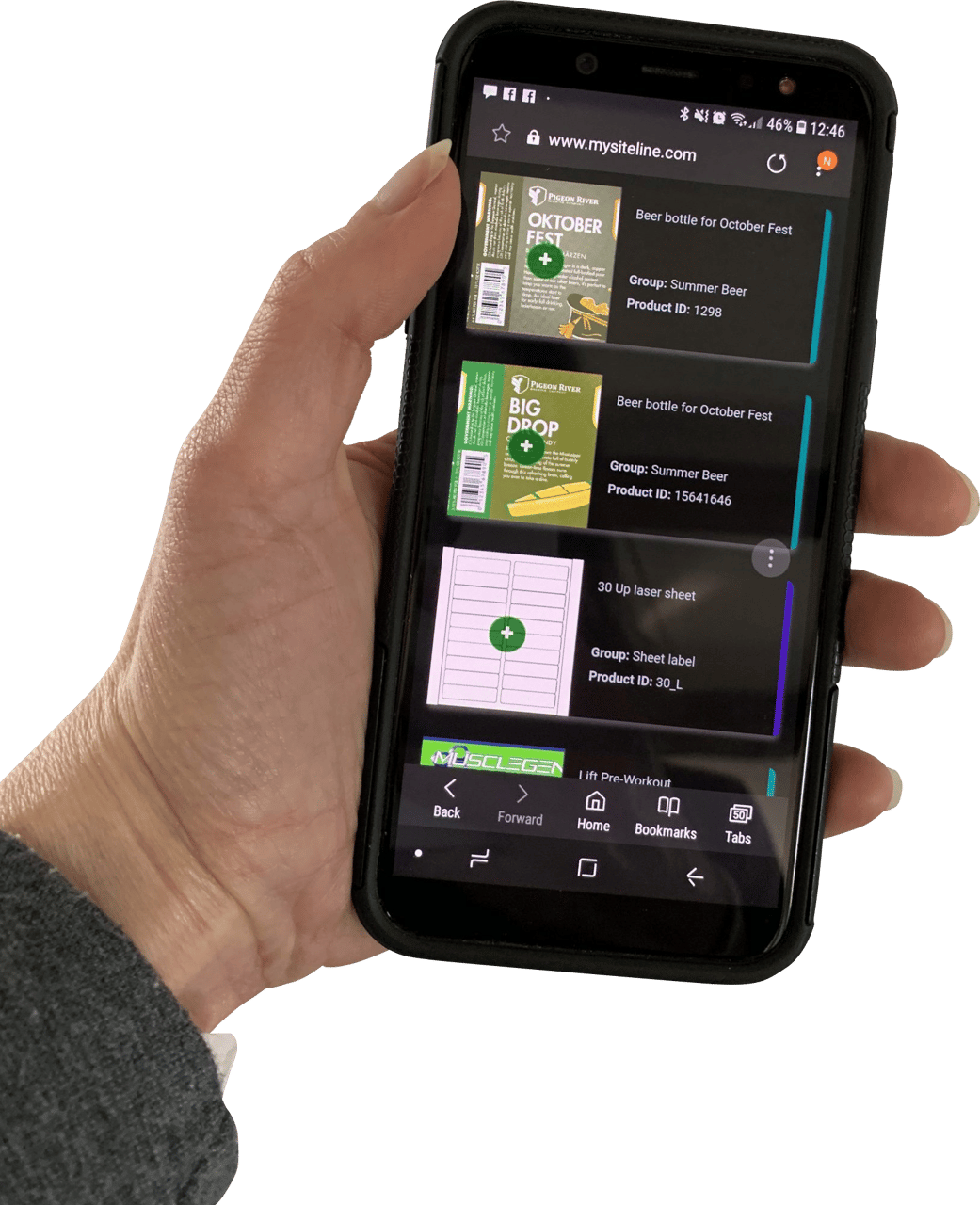

Another example of software finding efficiencies for printers and converters is LabelTraxx and Amberley Labels. Milwaukee-based LabelTraxx helped Amberley Labels, part of the Coveris Group, to streamline its ordering and workflow scheduling with its Siteline interface and offers online access for its customers 24 hrs/day. The ordering system at Amberley Labels’ Blandford printing plant provides access to order status, label stock inventory, reorder information, past invoices and estimates.

Amberley Labels’ customers have access order status, label stock inventory, reorder information, past invoices and estimates via the Siteline platform that can be accessed via a smartphone.

Courtesy of LabelTraxx

“We wanted our customers to have full access to all their product specifications, order history and the Siteline collaboration tools,” says David Richards, managing director at Amberley Labels. “This is critical for the cosmetics industry, where long project timings of 18 to 24 months result in extensive data that can be lost in phone calls and emails.” Plus, the ability to order online for customers at all times is a “real advantage when working with many smaller startup brands with limited procurement resources,” according to Amberley Labels.

“Our next stage will be to implement the artwork approval module, then to include further automation via our workflows to deliver customer-approved files directly to press,” says Richards.

As shown above, these advanced software and platform additions are optimizing operations and adding more automation, while also eliminating processes for its workforce. Leaner companies mean higher volumes and usually increased profits.

September 2021 // flexpackmag.com