Focus – Automation

Bosch Rexroth offers ctrlX AUTOMATION open automation platform

With the new ctrlX AUTOMATION platform, Bosch Rexroth has eradicated the traditional boundaries between machine control systems, IT and the Internet of Things. Centralized and decentralized automation topologies can now be created flexibly with the scalable platform. With a Linux real-time operating system, open standards, app programming technology, web-based engineering and a comprehensive IoT connection, ctrlX AUTOMATION reduces the engineering time and effort by 30% - 50%. ctrlX AUTOMATION offers the choice to program in IEC 61131, PLCopen or G-Code, or in other conventional high-level or Internet languages. Configuration and commissioning of automation components is completely web-based, eliminating the need to install software. Also, a virtual ctrlX AUTOMATION system environment is available, enabling programming without hardware. The company says that ctrlX AUTOMATION cuts the engineering time and effort by 30% to 50%.

Photo courtesy of Bosch Rexroth

Focus – Automation

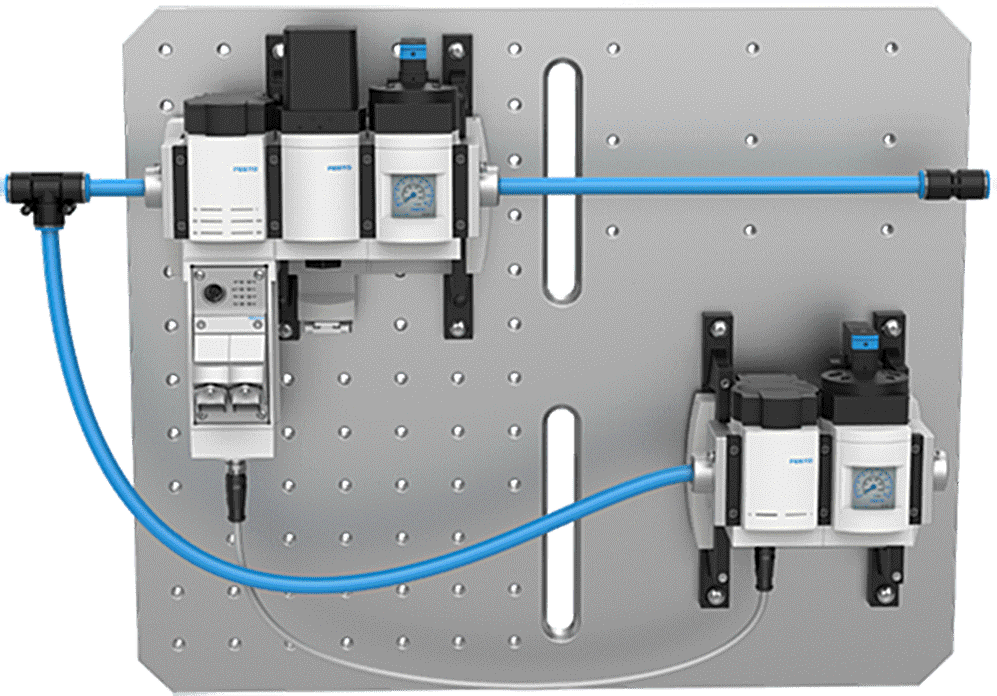

Festo Adds Solutions to Compressed Air Energy Saving Platform

Festo has expanded its intelligent pneumatic energy savings platform with the MSE6-C2M (C2M) and the MSE6-D2M (D2M). These modules can pay for themselves in less than a year with the energy savings accrued, says the company. The platform provides actionable information that supports quality production. The modules automatically shut off the air supply to a machine when in standby mode, thus reducing energy consumption. They monitor system pressure and flow information in real time and enable faster response to compressed air leaks. The units flow up to 5,000 liters of compressed air per minute; program easily; connect to Festo MS series air preparation units, including the MS6-SV safety valve; and are suitable for new and existing machines. The C2M combines a proportional pressure regulator, on/off valve, sensors and fieldbus communication. It monitors the flow rate and, when production is not taking place, automatically shuts off after a defined idle time. The D2M module is similar, yet completely depressurizes the system and provides leakage detection and process data acquisition for condition monitoring.

Photo courtesy of Festo