ACHIEVING EFFICIENCY

Robotiq’s palletizing solutions are highly advanced when it comes to automation.

Courtesy of Robotiq

Advancements in materials and machinery have made the palletizing process much easier.

By Bobby Douglas

The palletizing process in the packaging industry has undergone some major transformations in recent years. Pallets themselves are getting bigger, more durable and even more sustainable, and from a machinery perspective, the demand for automation has never been higher. In the past year, the industry has seen real advancement in all areas of palletizing.

Orbis, for example, launched a 60x48 inch pallet that is manufactured through Structural Foam Injection, making it extremely durable. The pallets are an optimal solution for heavy duty goods within the automotive and industrial sectors.

On the machinery side, Premier Tech recently launched TOMA™, a new product line that aims to accelerate packaging automation projects. The line’s first product is a palletizing solution featuring an advanced interface, which brings together industrial robustness and user-friendliness with collaborative robotics.

Meanwhile, BW Flexible Systems announced the launch of the SYMACH 3500S. The new machine is push-type palletizer that is ideal for high-speed stacking and palletizing for bags, bales, crates and cases.

Finally, Robotiq added to its already robust palletizing lineup with the AX20 and AX30. The highly automated solutions can build pallets as tall as 9 feet and can be used for a wide range of applications.

Learn more about all of these innovations below.

ADVERTISEMENT

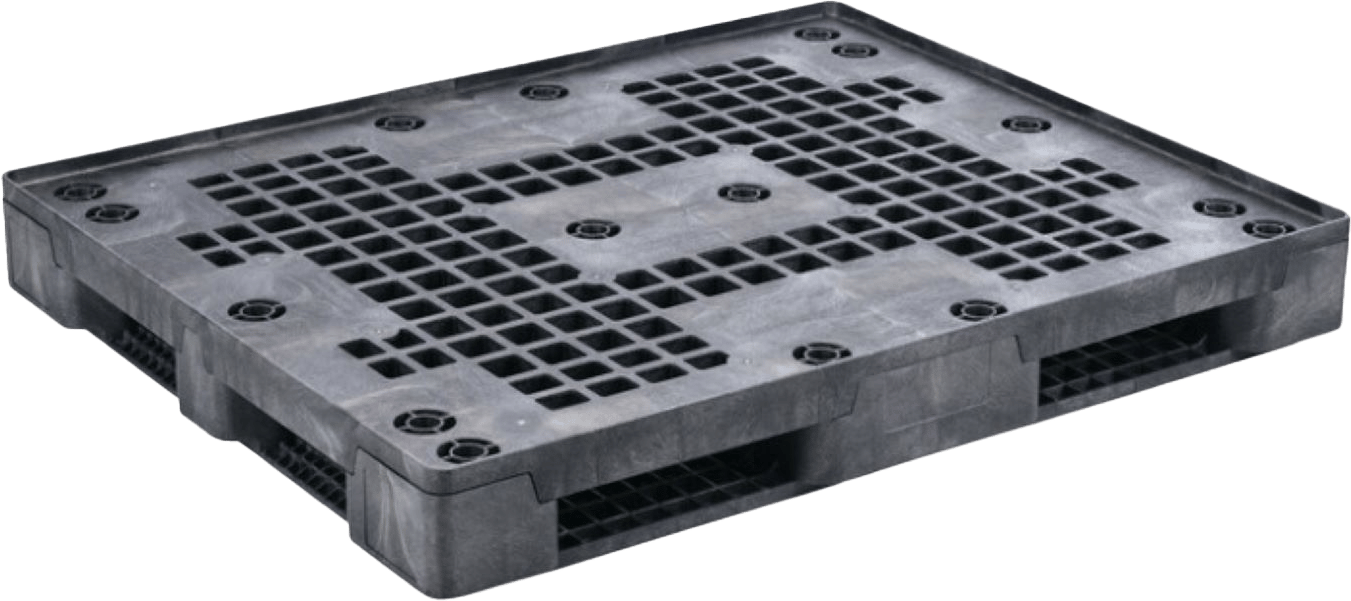

ORBIS Introduces 60×48 Industrial Pallet for EV, Powertrain Applications

ORBIS Corporation, a global leader in reusable packaging solutions, is proud to announce its latest innovation in sustainable packaging materials with the introduction of a new 60×48 industrial pallet specifically designed to cater to the unique requirements of EV and powertrain applications.

Manufactured through a process of Structural Foam Injection, the pallet boasts exceptional durability and reliability, making it an optimal choice for use within the industrial and automotive sectors. It is well-suited for transporting powertrain and EV components such as modules and longer battery components, offering compatibility with automation and edge-racking systems that enhance operational efficiency and versatility in handling and storage.

READ MORE

“We’re so excited to introduce our new 60×48 as this reinforces our ongoing commitment to provide reliable and durable solutions for the EV and powertrain industries,” said Bre Herbert, senior product manager. “With this new product, we’re able to offer enhanced load security and efficiency in handling and transportation.”

Measuring at 59.9×47.9 inches externally and 59.1×47.1 inches internally, the pallet features a continuous lip standing at 1 inch in height. This design enables edge racking capability and the option to incorporate metal reinforcements for added strength. Additionally, it is compatible with totes, EPP or thermoform trays, providing a comprehensive solution. ORBIS also offers a 60×48 thermoform topcap to secure unit loads.

Learn more about the new 60×48 industrial pallet here and by watching this video.

The new pallet is a suitable fit for the industrial and automotive sectors.

Courtesy of Orbis

COLLAPSE ARTICLE ABOVE

Premier Tech’s New TOMA Product Line Marries Palletizing with Automation

Driven by its commitment to innovation and supporting manufacturing companies in strengthening their operational efficiency, Premier Tech is introducing the future of automation thanks to its new product line TOMA™ — which aims to accelerate packaging automation projects through a comprehensive and intuitive do-it-yourself experience — hence delivering automation made friendustrial™.

The first product under the TOMA™ brand — and its underlying mindset — is a palletizing solution featuring the most advanced interface on the market, bringing together industrial robustness and user-friendliness with collaborative robotics. Thanks to its seamless integration requiring no coding, no engineering and no programming, both small and large manufacturers can access the benefits of automation, setting a new standard for efficiency and ease of use.

READ MORE

“We are launching more than a product line. We are launching a totally new approach to automation — we are launching the ‘Automation made friendustrial™’ mindset. Our teams at Premier Tech Systems and Automation have successfully merged industrial-level efficiency with ease of operation. This was achieved by leveraging the cobot technology from Fanuc, the worldwide leader in robotics,” says Jean Bélanger, president and chief executive officer of Premier Tech.

This launch is backed by more than 35 years of experience in automation and palletization, combined with new technologies in cobotics and the strong commitment of Premier Tech in ensuring that advanced technologies are made available to a wide range of manufacturers.

TOMA™ comes with a new innovative business model harnessing the power of an online, seamless and intuitive do-it-yourself configuration. It will enable companies to look at their packaging operations from a new perspective and implement automation projects where the financial feasibility was yet under pressure.

“TOMA™ cobots allowed us to enhance the work ergonomics of our teams, meet their needs — especially for night shifts —, and increase our productivity. This new solution is robust, intuitive and easy to program. With its agility and reliability, we can use it in various workspaces according to our needs,” says Pascal Gagné, operations manager at Groupe TAQ and launch partner.

Learn more about TOMA™.

The palletizing solution is Premier Tech’s first product under the TOMA™ brand.

Courtesy of Premier Tech

COLLAPSE ARTICLE ABOVE

BW Flexible Systems Debuts New Palletizer for High-Speed Operations

BW Flexible Systems is announcing the launch of the SYMACH 3500S. This push-type palletizer combines the company’s focus on design, innovation and customer centricity with intuitive controls — delivering high-speed stacking and palletizing for bags, bales, crates and cases. The SYMACH 3500S merges the original Thiele Master 3500 palletizer experience with the SYMACH palletizing platform.

“We’re excited by the many opportunities this innovation offers for manufacturers looking for a more robust palletizing solution," said Jan-Pieter Grootendorst, global product line leader for Bag Filling & Palletizing at BW Flexible Systems. "The 3500S was designed to solve specific palletizing challenges, including the risk of rejected shipments, manufacturing footprint constraints and ease of operation.”

READ MORE

One key differentiator of the 3500S is its high-quality stacking cage, which contains bags within the specified dimensions, reducing and preventing product overhang for a sturdier and more stable pallet. This ensures that pallets are square, making them easy to load and stack in the warehouse and truck.

"We understand that our customers’ customers demand perfect pallets and are known to reject shipments if any bag damage or overhang is detected," said Grootendorst. "Our SYMACH stacking cage eliminates that risk, ensuring that customer relationships are in good standing, and out-of-scope costs related to product waste are minimized."

The 3500S includes an operator-friendly human-machine interface, which supports 12 languages and facilitates communication with enterprise resource planning, warehouse management and manufacturing execution systems for seamless data exchange. Easy stacking pattern creation and easy recovery make the human-machine interface intuitive to work with. Occupying a more compact footprint than a robotic palletizer makes the 3500S an ideal choice for space-restricted environments.

"When laying out a palletizing line for manufacturers, we always consider their upstream and downstream needs," said Grootendorst. "For this reason, we offer many optional add-ons for pallet and slip sheet dispensing, conveying and pallet wrapping to provide a complete solution for their packaging line."

BW Flexible Systems is one of four divisions comprising BW Packaging, Barry-Wehmiller's packaging machinery group.

The HMI of the SYMACH 3500S supports 12 languages.

Courtesy of BW Flexible Systems

COLLAPSE ARTICLE ABOVE

Robotiq's AX20 & AX30 Palletizers Surpass Weight & Reach Limits

Robotiq has added to its line up the AX20 and AX30. Featuring the highest payload capacity and highest reach, the new Robotiq cobot palletizers are breaking new ground in the automation industry.

They can build pallets as high as 108 inches and handle packaging as heavy as 60 pounds. These new cobots are disrupting the industry, where until now the only solution for such applications was expensive and massive industrial robots.

READ MORE

Uniquely designed using a “coordinated axis” (or a ball screw servo axis), they respond to a wide range of applications and provide an unbeatable performance and reliability.

One company that has found significant success with Robotiq is TIDI Products. Using five of Robotiq’s solutions, TIDI was able to streamline their palletizing, going from a fully manual process to an automated one.

Robotiq’s Palletizing Solution brought about remarkable results to the company’s US Wisconsin facility, creating better working conditions for employees and significantly increasing productivity of their palletizing process.

The productivity gains from the first palletizing cell were 30%, which is very impressive. Subsequent cells have increased by a similarly impressive 25%. The robots have also solved the safety and ergonomics issues, which were among the team’s top concerns.

"One thing that we learned relatively quickly was the ability of the palletizing solution is vast, said Cameron Lemke, Value Stream Manager at TIDI Products. “It has a lot of capabilities that we didn't recognize right away. When we set it up, it was palletizing the same product each time. Now it's palletizing from two different machines, two different feeders, and it's still very successful. We're still continuing to learn and have those 'Aha moments,' which I think is great."

Robotiq sold its 500th cobot palletizer this summer. Learn more about their collaboration with TIDI here.

The new palletizers can build pallets of up to 9 feet tall.

Courtesy of Robotiq