New Ways to Protect Produce

From fiber-based packaging to labels with adhesive-free zones to prevent contact with product, companies continue to develop innovative ways to protect and package produce.

By Brad Addington

In this article, Graphic Packaging International (GPI) expounds upon the advantages of fiber-based solutions for produce packaging.

We also look at the innovative paper band for produce packaging created by Mondi and Swiss converter ATS-Tanner, and MULTIVAC sets its sights on sealing and labelling solutions for fruit and vegetable trays.

GPI: Bringing Fresh Produce Back to the Future with Fiber-based Packaging

Between evolving consumer sentiment and increasingly wide-reaching legislation in several key markets, the long-term role for plastic packaging in the fresh produce aisle is in doubt.

While packaging undeniably offers utility in protecting and preserving products through the supply chain, the days of shrink film, oversized plastic bags, and non-recyclable plastic trays are surely over.

Plastics squeezed out by legislation and consumer sentiment

This paradigm shift is occurring across virtually every sector, and fresh produce is no exception. The produce sector currently relies heavily on plastic in all its forms to protect, preserve, and market goods as they move through the supply chain.

The French government has recently introduced legislation to address plastic in the fresh product aisle, targeting over 30 fruit and vegetable varieties in its landmark 2022 single-use plastic crackdown. Supermarkets in France are no longer permitted to sell many fresh produce products in plastic packaging, a ban mirrored by the Spanish government just one year later.

READ MORE

Produce packaging solutions like the ProducePack™ Punnet tray, developed by Graphic Packaging International, uses material science to balance plastic reduction with maintaining shelf life.

Courtesy of GPI

The legislative picture elsewhere is equally clear. India has banned all single-use plastics, while Canada and the UK are set to implement their own single-use plastic bans that target specific categories. The EU, meanwhile, is set to overhaul its Packaging and Packaging Waste Regulation (PPWR) to reduce the environmental impact of packaging throughout its life cycle. It is expected to radically change the packaging that lands on the shelves of nearly half a billion European consumers when it eventually passes through the European Parliament.

Consumers, broadly, support attempts to make packaging more sustainable, and they are voting with their wallets. This is a pattern already being observed in the US, with more than half of US consumers being highly concerned about the environmental impact of packaging, while 60-70 percent said they would pay more for sustainable packaging across all end-use segments.

Forward-thinking growers and packers should take the lead from these significant global shifts – particularly those in states that have already made moves to ban certain plastic categories, such as California and New York.

Balancing sustainability with performance

It is important to remember among all of this, that sustainability does not merely mean swapping plastic for fiber-based packaging. Combating food waste is arguably the most important role of fresh produce packaging, as greenhouse gas emissions from food production dwarf those related to packaging. Legislators passing plastic packaging bans appear to agree – in France, for example, producers of certain fruits like apricots have been given extra time to find alternative solutions (although plastic is still expected to be wholly phased out by 2026) while avoiding an increase in food waste stemming from fruit spoiling or becoming damaged through the supply chain.

Fiber-based solutions must be at least as functional as traditional plastic produce packaging to meet the needs of the modern market. As a material, paper does not naturally possess the barrier qualities of plastic, so it requires an innovative approach that uses material science to balance plastic reduction with maintaining shelf life.

Achieving this requires a bespoke approach that looks at the needs of each product on a case-by-case basis. Solutions like the ProducePack™ Punnet tray, developed by Graphic Packaging International, provide that flexibility, making for an apt demonstration of the operational and sustainability benefits of a fiber-based solution.

The ProducePack Punnet tray is made from renewable plant-based fiber sourced from sustainably managed forests. If no barrier coating is needed, it can achieve up to a 100 percent reduction in plastic compared to a plastic tray (excluding the top seal film). For products where a barrier coating is needed, such as berries, the precise makeup of that barrier can be tailored to achieve the optimal properties required, while still keeping plastic use to a minimum.

It's a solution that meets the needs of today’s market — but importantly, it meets the needs of tomorrow’s market, too, in the likely event that state and federal governments begin to restrict plastic packaging for applications like fresh produce.

Fiber-based packaging can meet the demands of consumers, brands, retailers, and lawmakers, offering solutions that truly perform as we move toward a more sustainable future.

COLLAPSE ARTICLE ABOVE

Mondi and ATS-Tanner Launch Paper Band for Food Bundles and Multipacks

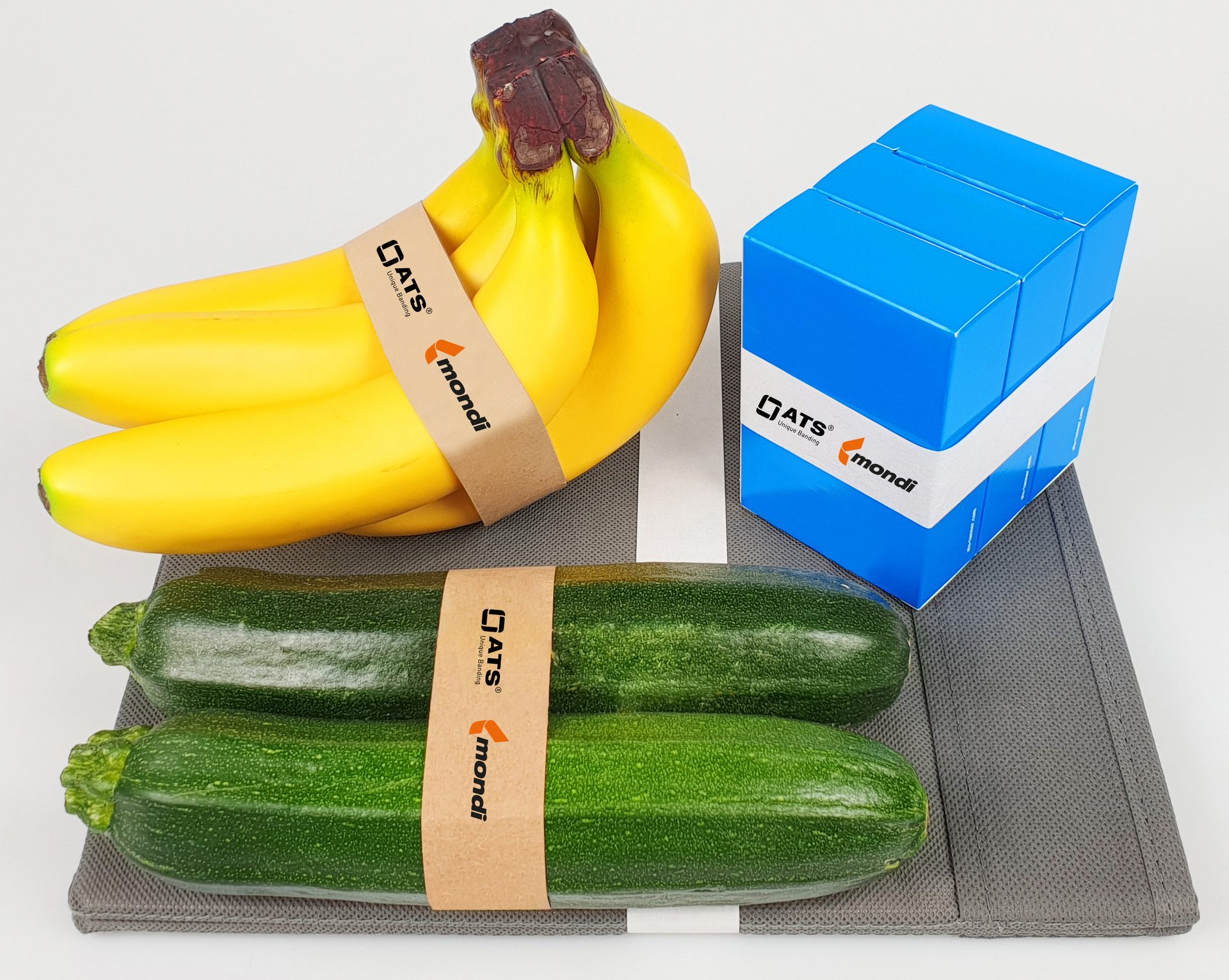

Mondi, a global leader in sustainable packaging and paper, has collaborated with Swiss converter ATS-Tanner to create an innovative paper band, which can hold individually labelled products or bundles reducing unnecessary plastic.

ATS-Tanner uses Mondi’s kraft paper Advantage MF SpringPack and converts it into a band by adding a functional barrier on both sides of the paper. The paper is then sealed using ultrasound, eradicating the need for any adhesive. This ensures that the products are secured with minimum packaging, reducing waste and delivering a cost-efficient solution. ATS-Tanner markets the coated bands under the brand name TruePaper.

READ MORE

The strength of Mondi’s kraft paper means it can hold weights of up to 45 lb, making the band perfect for fruit and vegetable bundles as well as multipacks of bottles and other consumer goods. The paper ensures excellent printing results, meaning brand, product, return and responsible waste management messaging can be communicated to the end user.

Mondi’s kraft paper used for the paper band is made from renewable, responsibly sourced and certified materials. It is recyclable in existing paper recycling streams across Europe, even fulfilling Germany’s ratio of 95/5.

“By combining world-leading expertise in sustainable packaging with ATS-Tanner’s machinery and skills, we have together created a system that offers great product protection while reducing unnecessary plastic,” said Carsten Breiter, International Key Account Manager Speciality Kraft Paper, Mondi. “This is the perfect example of strong collaboration producing a new solution that does just that.”

“We trialed various paper grades and Mondi’s kraft paper offers the required strength to substitute plastic packaging with this paper band,” said Serge Tanner, Owner & CEO, ATS-Tanner. “TruePaper is a resource efficient solution that can – depending on the banding machine used – wrap products measuring up to 1300 x 500 mm and is convenient to store. Using paper instead of plastic is not the only advantage: an ultrasonic banding machine from ATS-Tanner consumes 98% less energy than it would take to pack a like-sized delivery using a shrink wrapping machine.”

ATS-Tanner uses Mondi’s kraft paper Advantage MF SpringPack and converts it into a band by adding a functional barrier on both sides of the paper.

Courtesy of EMG

COLLAPSE ARTICLE ABOVE

MULTIVAC Roadshow Focuses on Sealing, Labeling Fruit & Vegetable Trays

As in prior years, this year will see the Roadshow from MULTIVAC Marking & Inspection stopping off at companies in Germany and other European countries.

From March onward in a live and convenient setting, customers will be able to learn all about MULTIVAC's innovative labeling and inspection solutions. This time the focus will be on high-quality and sustainable solutions for the closure sealing and labeling of fruit and vegetable trays.

When it comes to the marketing of fruit and vegetables, plastic-free and recyclable packs are very popular.

In addition to full-wrap labeling, which has already become established in the market, MULTIVAC offers two other high-quality and sustainable packaging solutions for fresh produce trays.

READ MORE

Whereas Top Wrap involves applying a label to the top and both sides of the tray, Top Close seals the tray closed just with a label from above. Both concepts are the ideal choice for fresh products that do not have to be packed under modified atmosphere or airtight in a vacuum.

This means that a label can be used to simply seal the tray closed and label it at the same time in one resource-saving operation — and it also meets the rising demand in this sector for sustainability.

Both labeling solutions provide a strong purchasing incentive thanks to their attractive label and recyclable pack. The self-adhesive labels on a backing material not only offer a large area for customer information and marketing purposes, they also open up a wide range of possibilities for product presentation in terms of material thickness and label shape.

It is possible, for example, to have cut-outs in the label, as well as adhesive-free zones, so that contact with the product is prevented. Perforations serve as opening aids and make the handling of the packs easy for the consumer.

Depending on the type of tray and its content, as well as the packaging materials used, a wide variety of solutions are on offer with MULTIVAC conveyor belt labelers, which support sustainable and recyclable packaging concepts.

Common to all these solutions is that the trays are automatically labeled on the run, and they are either fed in manually or transferred automatically from an upstream module. This provides tangible cost savings and very efficient processes, when compared with time-consuming, manual packaging solutions.

In the MULTIVAC Roadshow truck will be featured both Top Wrap and Top Close, which will be demonstrated on a L 310 Top Wrap/Top Close conveyor belt labeler, offering both concepts on the one machine. It can be integrated seamlessly into existing lines, or can also be used as a stand-alone solution with manual product infeed.

Additionally, the MULTIVAC Roadshow truck will feature a wide range of sample labels and packs, covering a huge variety of products from apples and berries to mushrooms, tomatoes and snack vegetables. Customers will be able to get comprehensive advice on a wide range of solutions to meet their particular requirements perfectly.