Package of the Month

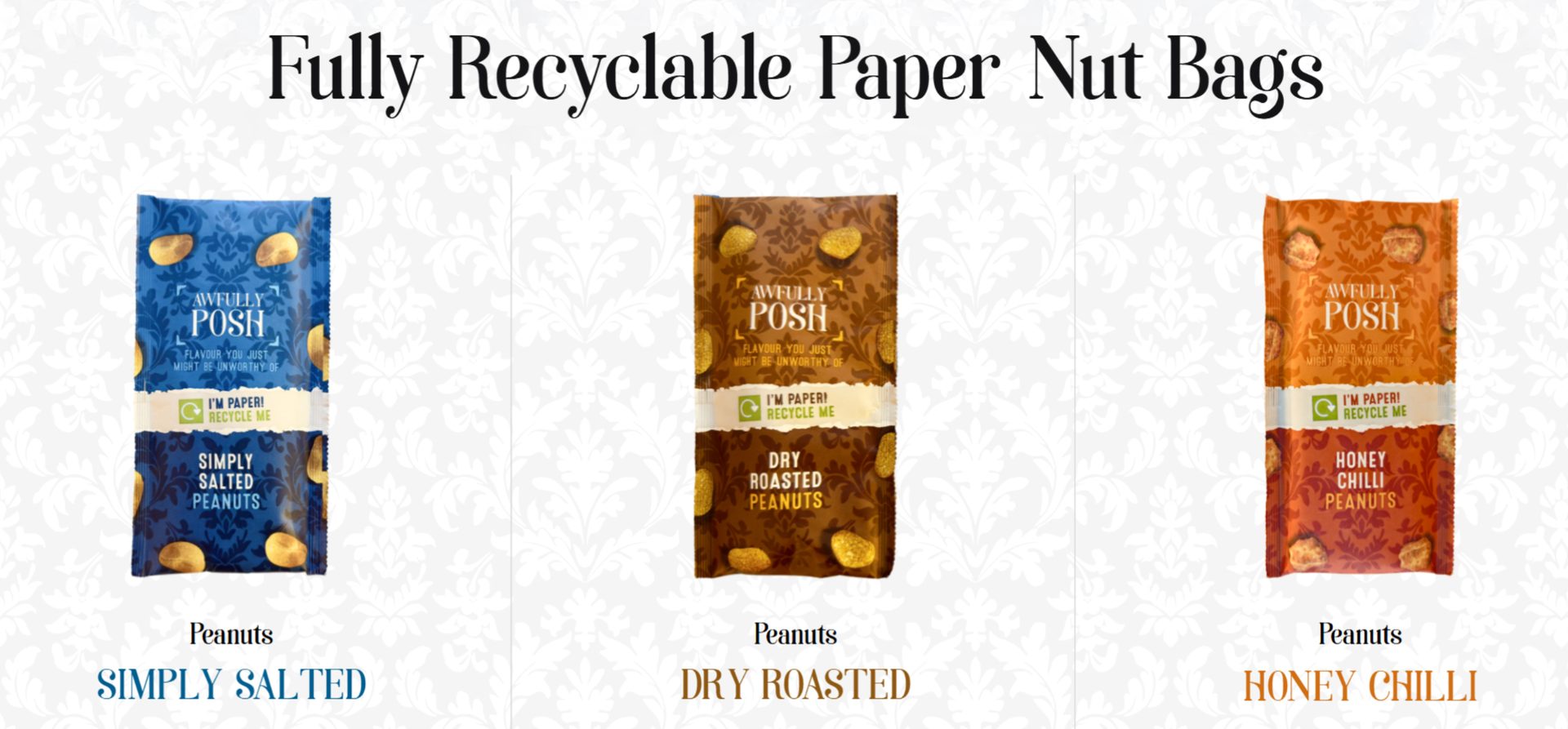

Awfully Posh Transitions to 100% Recyclable Paper Packaging for Peanut Range

The relaunched Awfully Posh peanuts will be available to the UK pub and bar market, with an initial launch planned in partnership with RedCat Hospitality.

Independent premium snack brand Awfully Posh has re-launched its peanut range in a 100% recyclable wrapper made from paper, replacing conventional nut packaging which is made from hard to recycle polypropylene.

Developed by sustainable paper packaging manufacturer, EvoPak, the new paper wrapper (known as MRCM) uses the same award-winning environmentally friendly technology as the world’s first fully recyclable crisp packet. The packaging incorporates a layer of Hydropol™ which makes unrecyclable packaging fully recyclable because it is dissolvable and biodegradable. Its marine-safe, non-toxic polymer technology developed by Aquapak, which specializes in developing high performance, environmentally safe materials to reduce plastic pollution and improve recycling, breaks down harmlessly in all existing recycling streams. If it does escape into the environment, it biodegrades completely, leaving nothing behind such as harmful microplastics.

The new packaging was developed by EvoPak, with a Hydropol layer, in addition to polymer technology developed by Aquapak and metalized paper from Nissha.

The wrappers have been certified as recyclable in standard paper recycling mills by OPRL, the only evidence-based on pack recycling labeling scheme. This means they feature the green recycle logo and can be disposed of in consumer curbside collections along with other paper material, unlike other nut snack packets.

Hydropol gives the paper a functional performance and also provides a high oxygen (OTR) barrier, enabling brands to switch to paper packaging. To meet high moisture barriers needed to keep the nuts fresh in transit and on the shelf, Hydropol is used in combination with Nissha metalized paper in order to give the moisture barrier required for this application.

Tom Lock, Founder of Awfully Posh, commented: “It is fantastic to have an environmentally responsible packaging solution that protects the planet and our premium nuts. This paper innovation has the potential to transform snack packaging as we know it and we are proud to be one of the pioneering users of the new technology.”

Courtesy of Awfully Posh

Lacerta Group Launches Seal N’ Flip™ for Prepared Food Packaging

Lacerta Group, LLC has announced the rollout of its newest innovation, Seal N’ Flip™ packaging. Coming at a time when food retailers and brands are focused on their bottom line, the Seal N’ Flip design is estimated to reduce packaging costs by up to 25%. The new design flips the script on traditional packaging, placing the lidding film on the bottom. This results in a product-forward display that is eye-catching, elevates shelf appeal to consumers, and is estimated to reduce the use of plastic by up to 50%.

Unlike standard film lidding formats, the Seal N’ Flip™ construction puts the food in the spotlight. It is ideal for showcasing cut sandwiches, wraps, hoagies, snacks, and other ready-made offerings. This gives brands a powerful visual merchandising advantage while maintaining the functional benefits that packaging film provides, such as tamper resistance, leak protection, and a lower carbon footprint over the product’s lifecycle.

“Grab-and-go shelf real estate - especially in the refrigerated section — is highly competitive, so we designed the Seal N’ Flip™ packaging and stand to give brands a distinct edge,” said Craig Muldrew, Lacerta’s VP of Marketing. “By using the stand to position products vertically to feature our unique back-facing lidding design, prepared foods are front and center, creating a standout, premium look that speaks to the way consumers shop - with their eyes first.”

The introduction of Seal N’ Flip™ advances Lacerta's broader vision to drive the food packaging industry forward, setting a new standard for innovation and environmental responsibility. Lacerta's commitment to sustainability helps offer customers a pathway to achieve their ESG goals while benefiting from the company's integrated design and manufacturing capabilities, speed to market, and customer-first approach.

The product will be generally available in August 2025.

Courtesy of Lacerta Group

Marks & Spencer Launches Paper Fiber Ready Meal Tray

Marks & Spencer has announced a trial of a paper fiber alternative ready meal tray, on its fan-favorite Fiery Chicken Tikka Masala. The first-to-market tray is still as convenient as ever, suitable to be cooked in both the microwave and the oven.

Made of renewable paper fiber, the FSC-certified tray is available in stores and is easily recycled at home as paper, with no need to remove the thin plastic lining.

Due to the technical differences of cooking methods between an oven and a microwave, ready meals have long presented a challenge to the industry as plastic has been the most resilient material for both. The new M&S tray has been designed and tested to make sure it is suitable for both options so customers can still enjoy their delicious dinner however they prefer to cook it. The tray is made of cardboard created with renewable paper fibers so it can be easily recycled at home in paper recycling.

At the end of last year, M&S met its target to remove 75 million units of plastic in 2024/25 ahead of plan. The brand has committed to remove one billion units by the end of FY27/28, as part of its Plan A roadmap to net zero by 2040 and is halfway to this target with 500m units removed by the end of March 2025.

This project is in partnership with 2SFG and GPI.