2 Minute Machine TALK

BY Kristin Joker

Packaging Strategies asked SOMIC America, Inc. to provide its single- and multi-component machine capabilities. First, a look at what’s trending:

While the single-component packaging systems are currently the lions' share of machines that we [SOMIC] provide to our North American customers, the trend is toward multiple-component packaging machines. The retail-ready tray with cover systems are the predominant packaging formats in the European market, and like most packaging trends they eventually find their way to the U.S. These multi-component packages offer several distinct advantages over single-component cartons and cases. From a retailer perspective, it eliminates the need to tear a case apart for display purposes and provides a more consistent, clean look on shelf. Since the package consists of two separate components, each part can be designed for its intended use. The tray can be manufactured from a higher-end material with better print qualities, therefore enabling the product to stand apart from the competitor’s display on shelf while the cover — which serves primarily to contain and protect the product during distribution — can be plain, unprinted kraft corrugated. This separation of the material can offer options unobtainable with a single component, which must all be the same material.

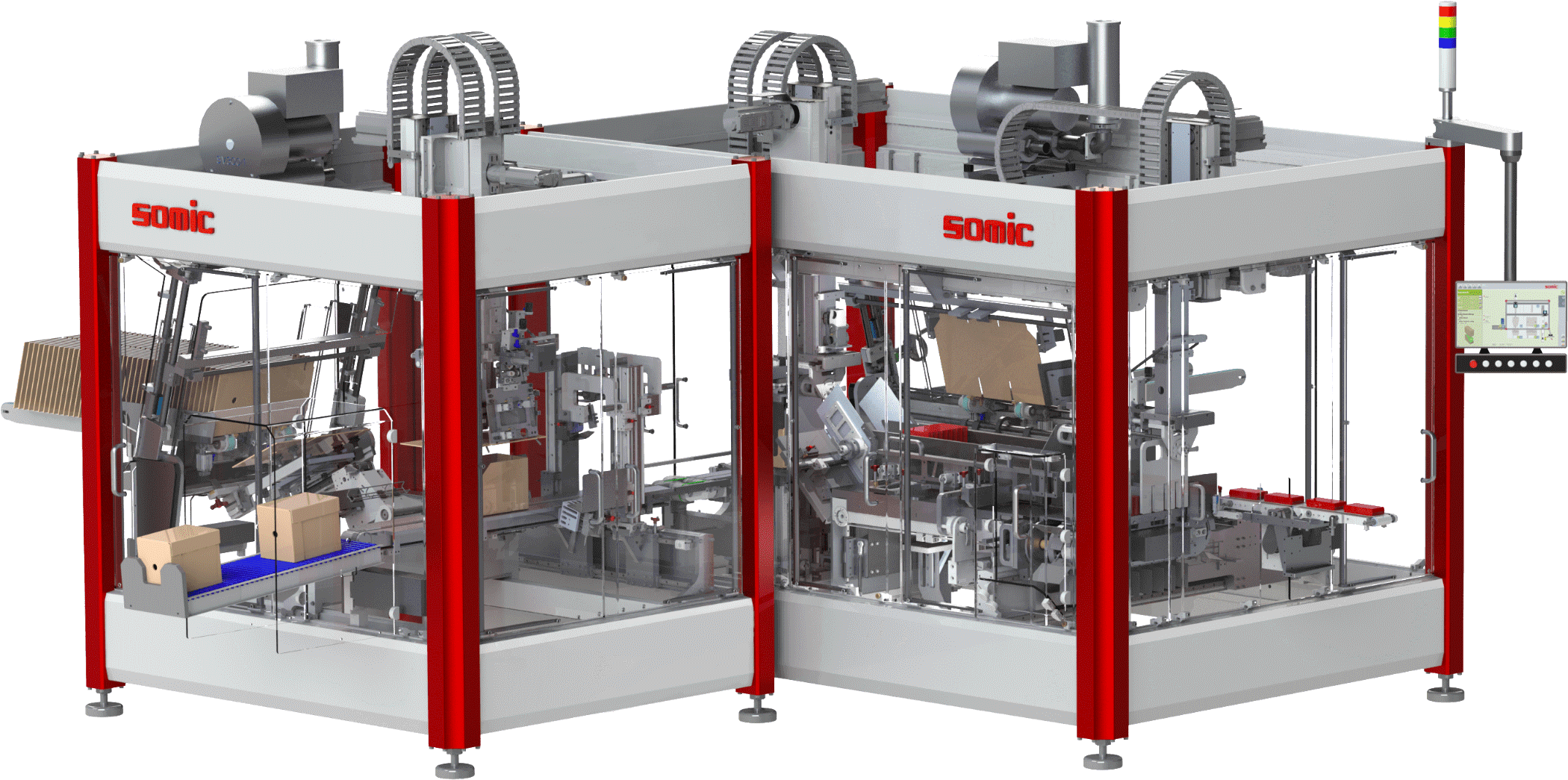

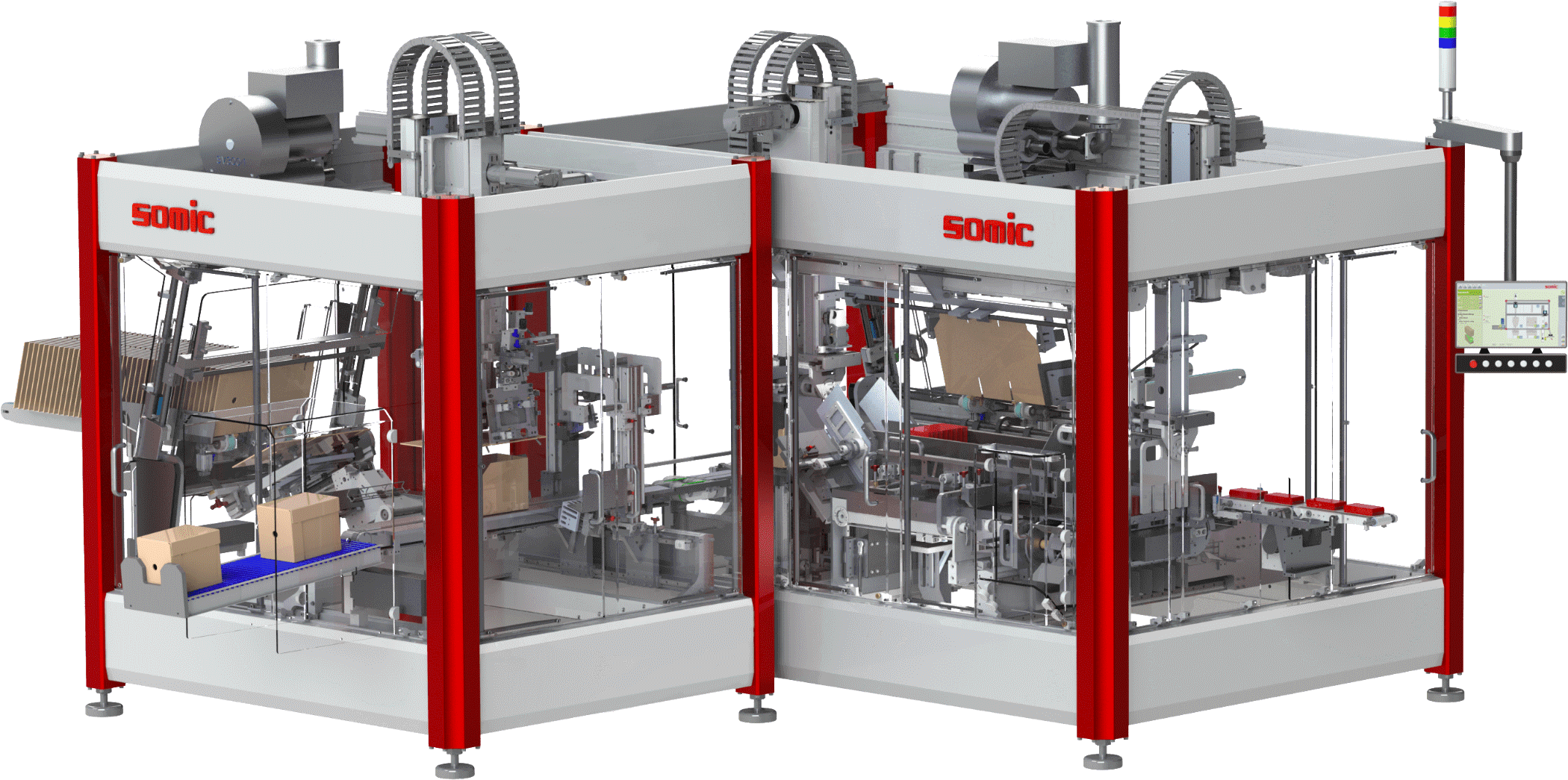

Manufacturers looking to make the most of their floor space have turned to SOMIC for compact, end-of-line packaging solutions such as the 424 T2-D multipurpose case packer.

How to know when to repair an existing machine or purchase a new one?

Repairing or upgrading an existing machine is oftentimes a practical and effective way to extend the useful life of an existing machine. There are several considerations that should be taken into account. I would evaluate the control system to ensure that it is capable to continue to operate the machine effectively while maintaining serviceability in the foreseeable future. The mechanical components of the machine should also be evaluated to ensure they are robust enough to provide enough useful life to justify the machine repair or upgrade. Finally, the speeds and efficiencies of the machine must match the line requirements to prevent the machine from being the bottleneck in the line performance, both now and in the future.

What are the new features?

Tool-less changeovers for a variety of format configurations, easy-to-operate HMI layouts and all servo-driven functionality. Recently, we designed a device that is built into the machine to manage corrugated blank variability. Warped blanks, which can be caused by environmental factors in a manufacturing facility, can be a major problem for automatic case packers. To help alleviate the issue, we designed a blank hold-down device to more positively grip the case blank as it feeds into the forming position on the SOMIC case packers. This device is a servo driven hold-down unit that can be retrofitted to existing machines or added to new machines. This device virtually eliminates any downtime related to excessively warped blanks being fed into the machine.

The SOMIC ReadyPack case packs up to 18 packaged units per minute as a tray packer and 12 per minute as a wraparound model. See the demonstration at PACK Expo Las Vegas.

What are some immediate ROI you can expect from a new SCP machine?

The return on investment with the SOMIC case packers varies depending on rates and run time. That said, our typical installation where a customer is moving from hand packing to automated packaging will deliver an ROI anywhere from 18 months to three years and is dependent on labor rates and complexities of the current plant environment. One area that is rarely included in the ROI of an automated packaging system is the real estate on the manufacturing floor. Our machines are significantly smaller than most case packers, therefore they consume less valuable production space. Retailers know what a square foot of retail space is worth to them on an annual basis, yet in manufacturing this is rarely included when conducting an ROI analysis. I believe this attitude will change in the future as manufacturing space becomes more limited.

Questions answered by Peter Fox, SOMIC America, Inc. Fox is a 30-year industry veteran. He previously served in various capacities at Delkor, Interpress Technology, Kraft Foods and The Pillsbury Company.

Courtesy of SOMIC

Nitin Chavan / Creatas Video+ via Getty Images Plus