Auto-Coiler for Customizable Paper-Based Solutions

Ranpak Holdings Corp. has launched its PadPak Auto-Coiler solution, an on-demand system that creates a sustainable, paper-based cushioning solution to displace foam and plastic. The machine automatically forms the company’s pads into a protective spiral disc that supports a variety of products, including heavier items that exceed hundreds of pounds. The technology is designed for very heavy, dense or high-value products that are typically difficult to ship. Industries that have a need for this increased level of protection include industrial manufacturing, home furnishings, medical equipment and automotive.

Courtesy of Ranpak

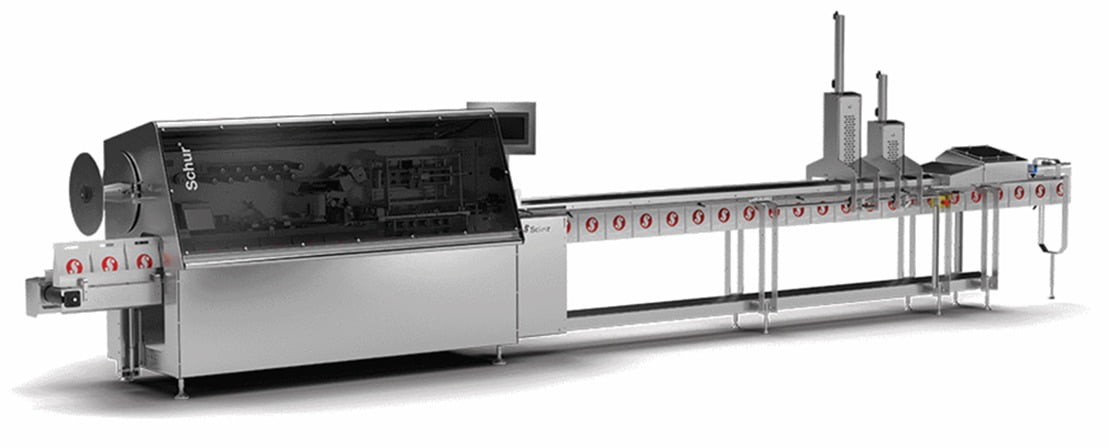

Double- and Triple-Bag Sterile Products

The SchurStar Concept Packaging Machine offers a fully automated double and triple bagging of sterile products. Integrated robots collect and insert the products into the bag — single and double index filling — and fold the bag top down. Integrated air evacuation units do likewise handle these steps fully automatically. Irradiation dots can be placed automatically onto the bags. One operator is required to keep an eye on the control panel, continuously providing product supplies to the conveyor. Double or triple bagging of pharmaceutical items is required when its final point of use is an operation theatre or another vulnerable area, requiring extreme hygiene measures.

Courtesy of Schur

New Laser Coding and Marking Solution for Metal Decoration

UK-based DataLase announced the launch of a UV offset (UVO) litho metal decoration coating, designed for use on offset litho presses equipped with UV curing units. Suitable for use on treated tin plate, the functional coating can be used to help address the challenges faced by production and manufacturing companies with product coding requirements, such as printing QR codes and expiry dates onto primary packaging applications. It can be used for food and drink, home, pharmaceutical, medical and industrial packaging. The solution is suitable for non-direct food contact packaging applications and designed for tamper-proof, anti-counterfeit coding and marking.

Courtesy of DataLase

New Booster Compressor Packages Double Range

Kaeser’s new CNC line of booster compressors, delivers capacities from 28-281 cfm with pressures up to 650 psig. These fully enclosed and integrated units are available in 10-30 hp models. Each package includes a built-in aftercooler for optimized cooling and a sound-dampening enclosure for reduced noise levels and better machine protection. A reduced footprint, easy access design and simple connections are designed to simplify installation and maintenance. A complete sensor array and the Sigma Control 2 controller offers unsurpassed control and monitoring with enhanced communications capabilities for seamless integration into remote plant control/monitoring systems.

Courtesy of Kaeser

Fiber Laser Solution for High-speed Beverage Canning

Videojet Technologies announced its new Lightfoot canning solution. This laser canning solution combines a Videojet fiber laser with the speed of dual Lightfoot marking heads for beverage canning manufacturers. The Videojet Lightfoot canning solution is designed with IP69-rated marking heads and an IP65- rated supply cabinet designed to handle humid, sugar-laden or washdown environments. The canning solution is able to reach marking speeds up to 100,000 cans per hour. The all-in-one Videojet Lightfoot canning solution helps to eliminate the need for multiple suppliers and the use of incompatible components in coding operations.

Courtesy of Videojet