Special Advertising Section

CORPORATE PROFILES

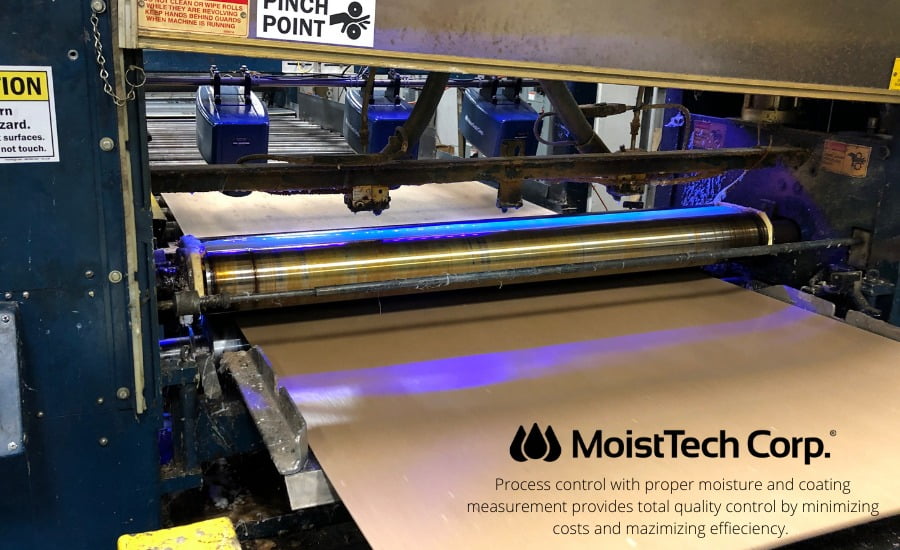

Implement Lean Manufacturing Principles with Moisture Control

Producers focus on cutting down on waste, reducing operating costs, increasing product quality, and maximizing plant efficiency. Wasted resources create the need to evaluate and implement lean manufacturing principles to identify the key area in which the manufacturing process is not operating at its peak efficiency. Often converting process efficiency is affected by variations in coat weight, inefficient moisture control, thickness and/or temperature issues. MoistTech Corp manufactures a state-of-the-art sensor that can play a large role in increasing and maintaining the efficiency of plant production. Maintaining the ideal thickness and coat weight in the production line can mean the difference between a quality product to provide your customers or wasted effort and material. Many basic properties of paper are greatly affected by its moisture content. Paper dimensions, flatness, conductivity, strength, and fold are among the more significant properties influenced by its moisture content. Moisture & coating technology provides a proactive path to avoid quality control issues. Installing measurement sensors throughout the process makes this easily achieved with proactive, immediate adjustments to the line. Immediate results are recorded and displayed every second to operating personnel via PLC, giving full control of the line. The IR3000 NIR sensors ensure feedback loops have predictable and repeatable results, even at high operating speeds. With implemented moisture monitoring, processing, and manufacturing, plants can produce large savings in little time. If there is no current method of moisture measurement in the production process, a large opportunity for increased efficiencies is being missed.

941-727-1800

info@moisttech.com

moisttech.com