Digital preprint’s use of aqueous inks and coatings ensures that the paper recycling process produces quality fiber in high yields.

Image courtesy of Georgia-Pacific

3 Ways Digital Preprint Increases Brand Value and Sustainability

These are important ways that producing high graphics corrugated packaging using digital preprint increases a brand’s image in the eyes of consumers.

By Johann Perera

As consumer demand for sustainable products continues to grow, brand value is increasingly linked to sustainability. For example, a 2019 survey by Accenture found that 83% of consumers believe it is important or extremely important for companies to design products that are meant to be reused or recycled. Sustainability has clearly moved up in the rankings of what consumers want.

That desire for sustainability extends beyond the product itself, with consumers paying close attention to the sustainability of packaging as well. A recent study by Dotcom Distribution noted sustainable packaging is more likely to gain shoppers’ attention than any other environmental factor, which presents a tremendous opportunity for brands.

High graphics corrugated packaging is one of the best options for seizing the opportunities that lie at the intersection of sustainability and branding. In 2018, 96% of corrugated material was recovered for recycling, and nearly all of it was used to make new products. Marrying those sustainability credentials with the environmental and branding capabilities of digital preprint puts brands in a strong position to deliver on consumer expectations.

The following are three important ways that producing high graphics corrugated packaging using digital preprint increases a brand’s sustainability and value.

ADVERTISEMENT

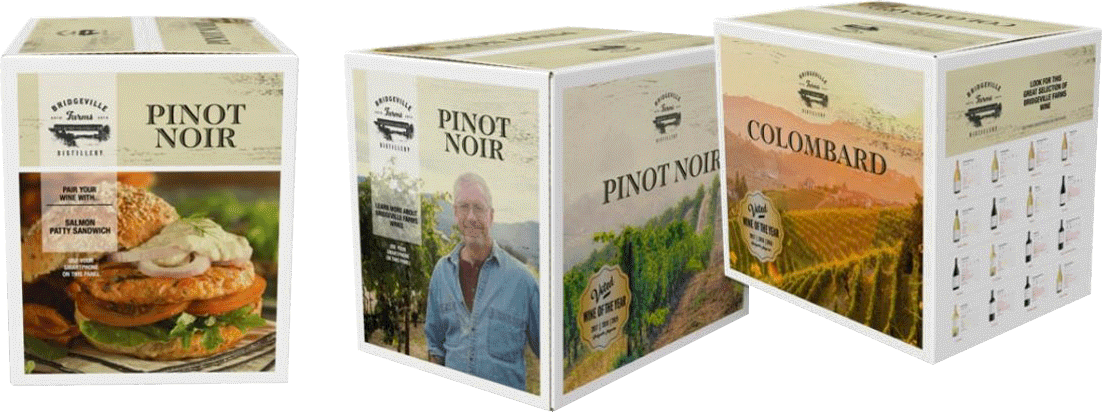

Increasing Brand Relevance, Decreasing Waste

Digital preprint’s speed and versioning capabilities allow brands to get creative with packaging and increase their relevance to consumers. With turnaround times of only a few weeks and low minimum order quantities, brands can create seasonal or promotional packaging without fear of being stuck with several months’ worth of unused inventory. They can capitalize on regional loyalties and tastes by creating several versions of a package design and running it as a single, side-by-side print job. Or, as we saw earlier this year when COVID-19 turned everything upside down, brands can quickly execute promotional or charitable campaigns and drive results by featuring them on packaging.

While any one of these creative tactics is technically feasible using traditional print methods, it would most likely lead to large quantities of obsolete packaging due to traditional print’s larger minimum order quantities. Digital preprint’s lower minimum and nimble ability allows brands to print only the packaging they need, just when they need it. In turn, that reduces warehousing capacity needed for packaging inventory and it decreases inventory obsolescence.

Digital preprint’s lower minimum and nimble ability allows brands to print only the packaging they need, just when they need it.

Image courtesy of Georgia-Pacific

Winning Consumers with Recycling

A recent survey revealed that 71% of shoppers feel positive toward companies that use only recyclable packaging. The same survey showed that consumers also gave high marks for companies that use packaging made with recycled materials (68%) and renewable resources (67%). If you’re keeping score, that’s a win-win-win for corrugated packaging.

Corrugated packaging is well known as a highly recyclable option, and more of it is recovered for recycling than any other packaging material. Digital preprint’s use of aqueous inks and coatings ensures that the paper recycling process produces quality fiber in high yields, while also meeting worldwide regulatory requirements that address a broad range of health and environmental considerations. Aqueous inks offer food-safe printing, do not contain hazardous air pollutants and emit low levels of volatile organic compounds (VOCs).

Digital preprint helps enhance many traditional corrugated production processes to remove hidden waste.

Image courtesy of Georgia-Pacific

Reducing Waste and Improving Efficiency Throughout the Box Lifecycle

Recycling is great, but it’s only one stage in the lifecycle of a corrugated box and can’t be used to accurately measure a package’s sustainability. Understanding how a package is manufactured and distributed provides a more complete picture of its sustainability — and digital preprint offers several advantages.

With digital preprint, many traditional corrugated production processes can be enhanced to remove hidden waste. For example, digital preprint can eliminate the need for litho labels, especially for large format boxes. Not only does it remove waste associated with the label production and application processes, but it also reduces the corrugated box from four layers to three layers, which makes it lighter for transport.

Digital preprint allows for the use of lighter-weight print liners than most three-layer laminated corrugated products as well as some late-stage digitally printed products and flexo post-print products. Using lighter grades of printed liner substrates can help reduce the carbon footprint associated with transportation.

Traditional print methods require individual print plates to be produced for each color in a package’s design. A typical box, display or label frequently requires multiple print plates to produce the desired print outcome. In most cases, these print plates are not reusable over time. Digital preprint eliminates the use of print plates, reducing heavy metals and plastics waste. Eliminating plates also removes water waste associated with traditional printing’s ink wash-up and reclamation processes.

Digital preprint also reduces transportation costs and supply chain inefficiencies by using a national network of box plants for corrugating and converting. Shipping a truckload of printed rolls from a central preprint location to one of the locations within a distributed corrugating and converting network can be 10 times more efficient than shipping finished sheets or boxes from that same location.

Digital preprint offers a combination of sustainability benefits and branding advantages that are perfectly suited for today’s highly competitive, volatile business environment.

Johann Perera is area general manager at GP Hummingbird.