Cartoning

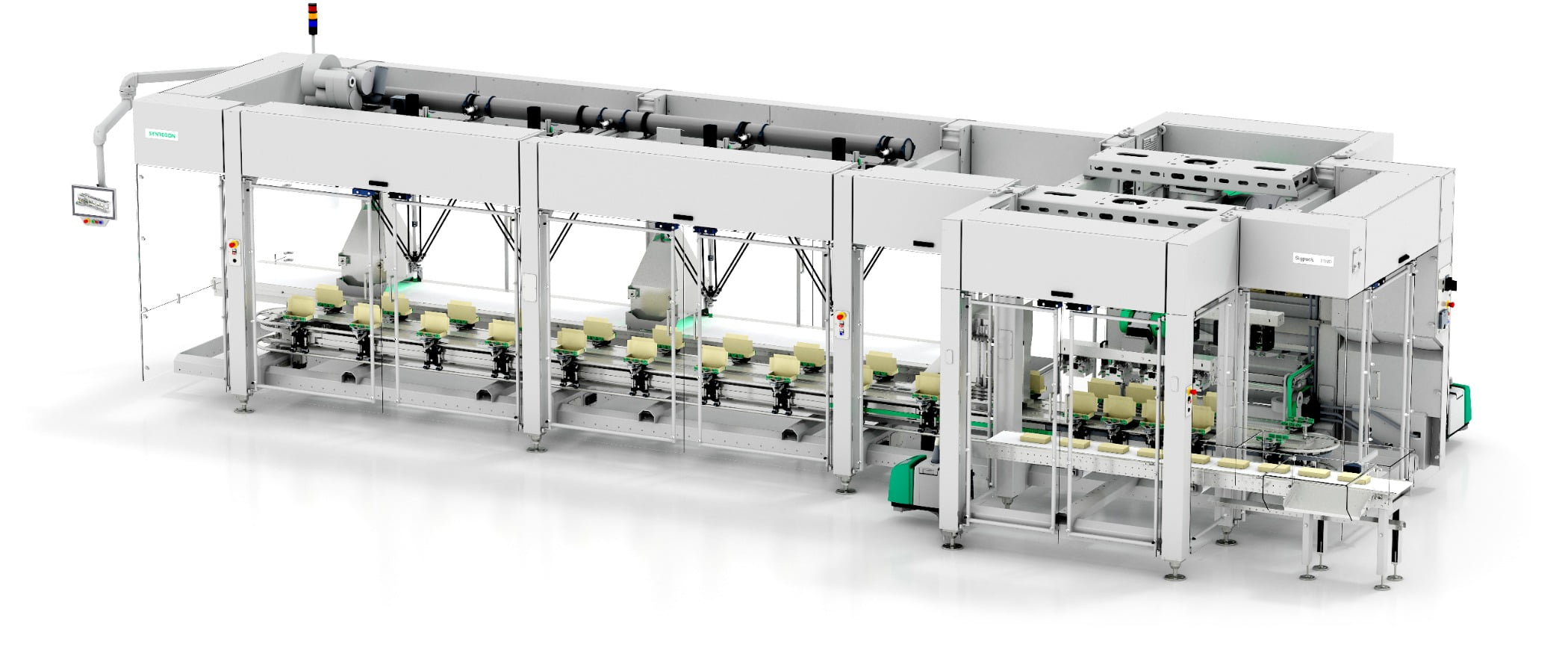

Sigpack TTMD Cartoner with Integrated Delta Robots

Syntegon has expanded its secondary packaging portfolio with the Sigpack TTMD, which combines core technologies of the TTM platform with one or more seamlessly integrated Delta robot cells — hence the D in the product name. The robotic solution's camera-based vision control system detects products on the infeed belt. The delta robots pick single or multiple products arriving in random order and reliably place them in cartons, trays or other containers according to specifications. To enable additional packaging flexibility, the new topload cartoner can also simultaneously pack different products from several infeed processes. The Sigpack TTMD uses the tool-less format changeover concept from the TTM platform, enabling a vertical restart after each format change.

Photo courtesy of Syntegon

Packing

Smart Top-Loading Case Packer For Flexible Packaging

The Quest Quik Pick QP200 is a robotic top-load case packer or pick-and-place solution optimized for products in flexible packaging. The Quik Pick uses the Fanuc vision system to identify, locate and track incoming pouches by detecting the topography and center of gravity to detect the proper high point for picking. The QP200 is a versatile machine, capable of handling delicate flexible packaging to very complex, challenging products — all within a compact footprint. The QP200 is designed for a variety of applications. Powered by the QPick dynamic case packing software and IQ Lighting, the intuitive QP200 allows operators to easily interact with the machine and identify ways to improve their interactions.

Photo courtesy of Quest