Rabbit Hole Distillery Touts Partnership with Independent 2, Domino Digital Printing

Rabbit Hole Distillery produces one-of-a-kind American whiskey by using its own original recipes, but the whiskey is not the only element that makes the company unique.

By Bobby Douglas

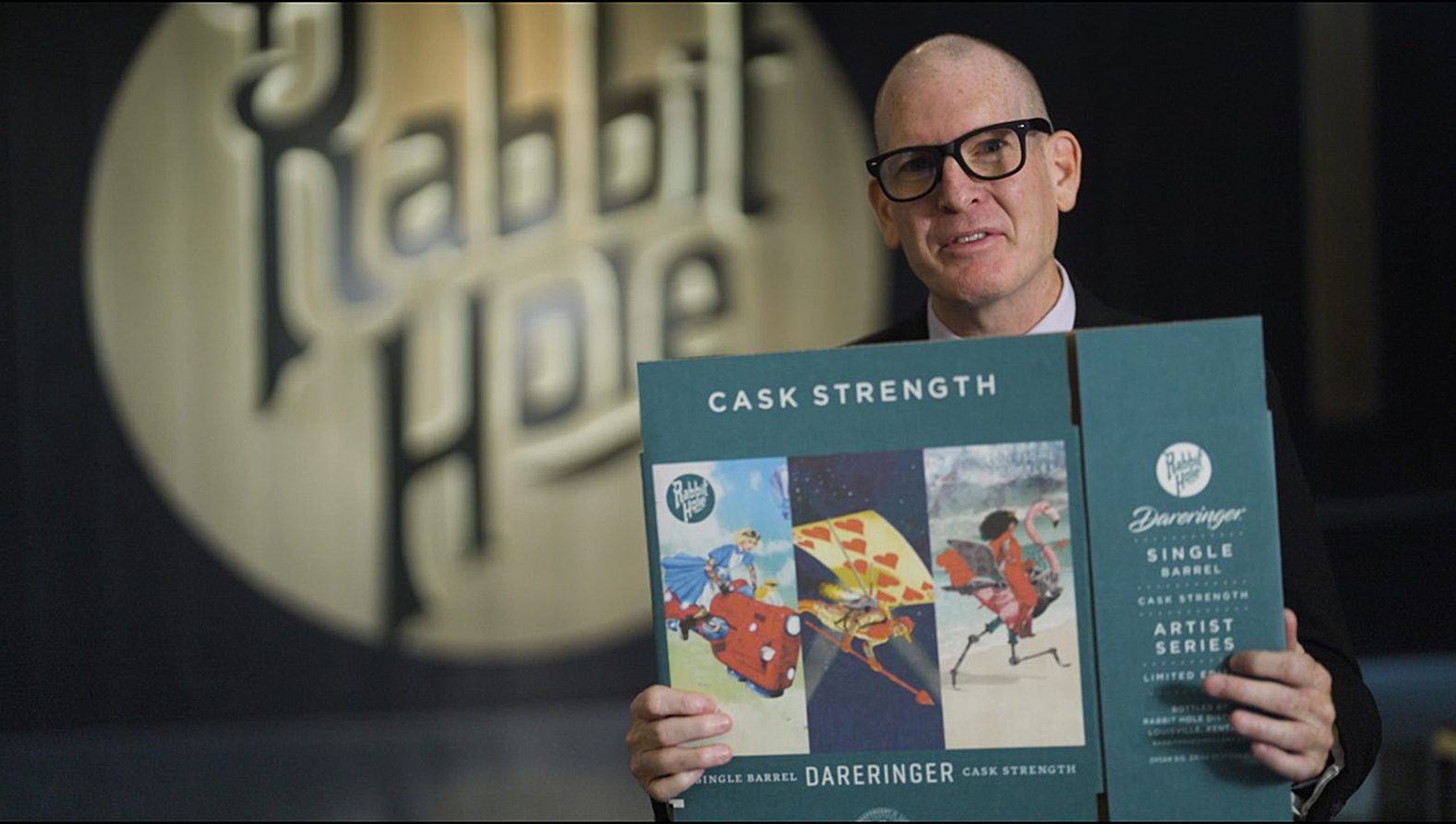

Rabbit Hole Distillery, located in Louisville, Kentucky, produces one-of-a-kind American whiskey by using its own original recipes, but the whiskey is not the only element that makes the company unique.

Thanks to a partnership with Independent 2, a privately-owned and operated corrugated manufacturer, Rabbit Hole has been able to create shipping cases with tremendous shelf-appeal that help drive sales for the company.

Domino’s X630i digital aqueous inkjet corrugated press helps streamline the printing process.

“We make one-of-a-kind original works of bourbon. Each one of our whiskeys has its own grain recipe that’s not like anything else on the market,” said Dac Austin, Creative Director of Rabbit Hole. “One of the things that’s necessary for what I do, is having a partner that has the ability to do modifications quickly, efficiently, and in real time. One of the relationships that we’ve built is one with Independent 2, who is our ship case provider. Their responsivity that we receive from their team is excellent, and that really resonates with what we do with our ship cases, and what we’re able to produce.”

In addition to its partnership with Independent 2, Rabbit Hole has also embraced digital printing with the help of Domino’s X630i digital aqueous inkjet corrugated press. A leading manufacturer and distributor of digital printing and product identification solutions, Domino has been able to streamline the packaging process for Rabbit Hole, which has been an invaluable benefit.

Austin explained how Rabbit Hole Distillery has teamed up with Independent 2 and Domino.

“The clarity, the color, and the product is outstanding,” continued Austin. “We are able to make edits with color, with typography… and see it within minutes. If we were to do this in a conventional manner, we would have had to shut down the press, take the plates off, remake the plates, reapply the ink, and wait for hours for this to happen.”

A full view of the various Rabbit Hole designs.

“All I had to do for this was create a new file, run it through the machine (Domino X630i digital aqueous inkjet corrugated press) and it’s instantaneous. There’s no mixing of inks, there’s no wipe-up or clean-up for the machinery. It’s just moving the board through, and it works effectively and efficiently. That is something that is magnificent in what we’re able to do. And it shows the merger of the digital and corrugated world.”

Learn more about Rabbit Hole Distillery, Independent 2, and Domino.