Q&A: How E-Commerce and Sustainability Intersect

We caught up with Darek Lewis, director of packaging for Veritiv, about innovations helping to bridge the sustainability gap with from-home shopping.

Consumers are getting serious about sustainability and the products they buy. How does that affect packaging?

Over the past few years, we have seen an uptick in demand for brands to prioritize sustainability in packaging. As a result, it’s become even more important that packaging is dynamic: made of sustainable, recyclable materials, as well as being protective, aesthetically pleasing and engaging. Luckily, there is a vast selection of excellent sustainable packaging materials to meet a variety of needs. Some examples include ocean-bound plastics, sugar cane paperboard and molded fiber created using HP’s tooling solution for manufacturers. These materials are made from renewable and/or recyclable materials. By putting the customer’s goals first, Veritiv experts find the most effective material to help each customer reach its sustainability goals while helping the product arrive intact.

Beyond the packaging that touches products, another way to reduce environmental impact in packaging is palette optimization. Veritiv offers a Secure Wrap Analysis tool that analyzes efficient use of materials to not only protect products in transit but also result in less waste and support achievement of sustainability goals. Our Secure Wrap Analysis considers the pallet layout, film application methods, monitoring equipment, freight conditions and labor requirements. This approach reduces product loss with the long-term goal of ensuring product protection, optimizing packaging material usage and reducing labor requirements. These updates to a company’s packaging processes can have a big impact on sustainability.

ADVERTISEMENT

E-commerce has grown exponentially since the pandemic. How has that impacted decision-making for sustainable packaging products?

The demand for e-commerce has been increasing for years, but the pandemic transformed it from an option to a necessity for many consumers and forced companies to quickly shift away from their brick-and-mortar retail strategies. In fact, corrugated box shipments increased 9% from March 2020 to January 2021, according to Vox. When the pandemic put an unexpected halt to in-person shopping, many companies had to pivot to an entirely new business model without abandoning sustainability commitments or creating more waste. With the ability to source materials from global suppliers, Veritiv worked with each customer to creatively source sustainable materials and identify opportunities for optimization to continue to deliver packaging in a timely manner.

What products have you specifically been working on to meet the demand for both?

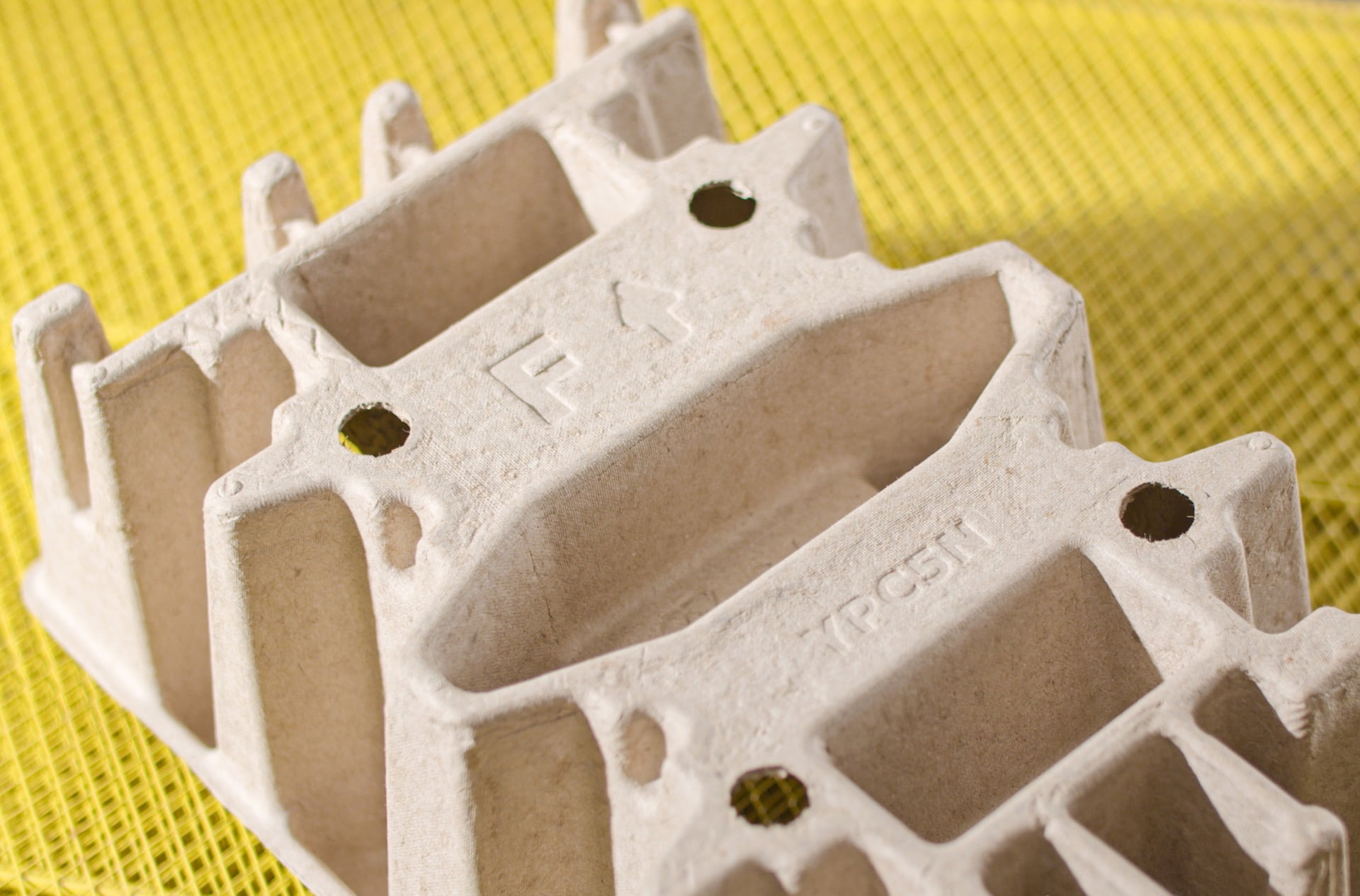

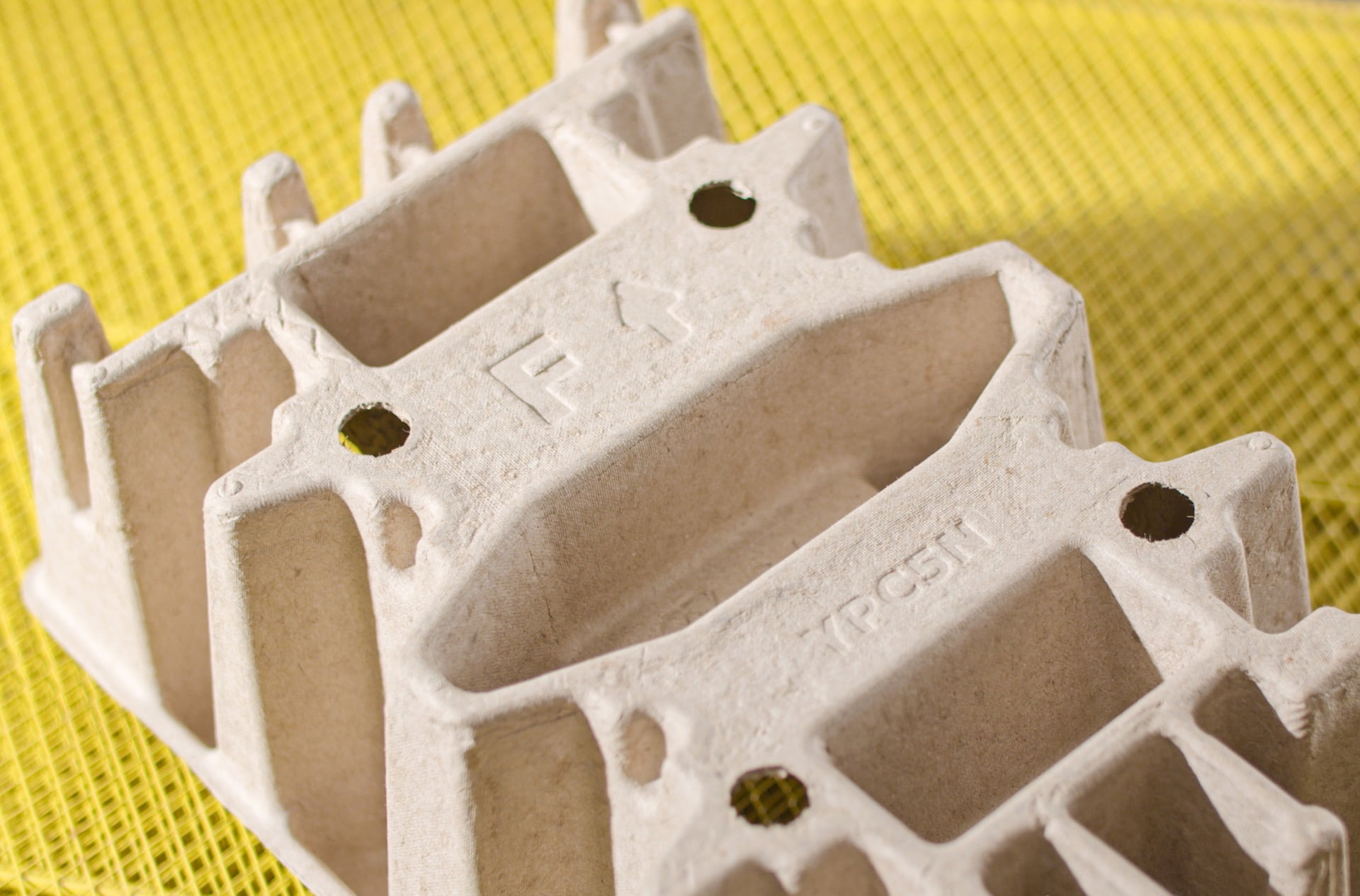

In September 2020, HP and Veritiv unveiled a new partnership. We’ve collaborated closely to design 3D printed molds for HP’s breakthrough new molded fiber solution. The ability to digitally design and produce molded fiber tools using the HP solution enables us to quickly create more innovative and sustainable packaging for our customers. The flexibility of 3D printing allows us to create a mold of any shape and size to produce custom packaging that better protects the product from damage during shipping. When a product arrives at the consumer’s door intact, it results in both a happy customer and a reduced operating cost for the company.

Created from 100% renewable materials, the packaging can be curbside recycled after delivery. As sustainability continues to be a priority for both consumers and companies, this solution allows Veritiv to design packaging that protects the product and the Earth.

HP’s 3D printed molds can lead to shorter production times and be more cost effective.

How can these products contribute to a client’s goals beyond e-commerce and sustainability?

Veritiv’s structural and visual designers’ goal is to create custom packaging where form and function are interwoven. HP’s innovative molded fiber solution offers a sustainable packaging solution that can be customized while also protecting the product. HP’s 3D printed molds are faster to design than other options, leading to shorter production times, and being more cost effective.

What’s the process like to determine what product(s) are right for clients?

No two customers are alike, which means no two packaging solutions will be the same. Whether our customers need to know the best materials to build their packaging solution, most cost-effective way to transport their product or opportunities to be more sustainable, Veritiv’s team asks the right questions and offers strategic counsel about, and provides access to, optimal solutions. Our team of packaging experts are dedicated to helping customers find the most effective and cost-efficient solution to reach business objectives.

Even after the pandemic it will be critical for companies to team up with agile partners.

Generally speaking, how much of what has been done to accommodate pandemic needs do you see extending to the “new normal” after the pandemic?

E-commerce has boomed during the pandemic and, as a result, more brands have invested more in the overall e-commerce experience for consumers, including packaging. Without the in-store experience to engage with consumers, packaging became a critical touchpoint. The package is now the first experience a customer has with the brand and can reassure their decision to buy that brand.

Even with widespread vaccine deployment, a certain segment of the population is still likely to remain cautious of in-person shopping and experiences — not to mention, consumers who realized they prefer the frictionless e-commerce experience simply for convenience. On the business side, the pandemic forced companies to quickly pivot to an e-commerce strategy, but lessons learned in supply-chain resiliency will persist as we get back to “normal.” It will continue to be critical for companies to choose partners who can be agile in adapting quickly to market changes, and themselves have staying power to provide the critical support their customers need now and in the “new normal” ahead.

Images courtesy of Veritiv and Fiber Innovation