FROM WINE

TO TORTILLAS

From properly counting out pharmaceuticals to guaranteeing the proper bottling of wine — and even ensuring that the wine bottles themselves are up to snuff — inspection, detection and vision systems play a myriad crucial roles in CPG packaging.

By Brad Addington

FROM WINE

TO TORTILLAS

From properly counting out pharmaceuticals to guaranteeing the proper bottling of wine — and even ensuring that the wine bottles themselves are up to snuff — inspection, detection and vision systems play a myriad crucial roles in CPG packaging.

By Brad Addington

From properly counting out pharmaceuticals to guaranteeing the proper bottling of wine — and even ensuring that the wine bottles themselves are up to snuff — inspection, detection and vision systems play a myriad crucial roles in CPG packaging.

By Brad Addington

Reporting by Packaging Strategies over the last several months reveals the innumerable applications of inspection/detection/vision equipment.

Most recently, Mettler-Toledo showcased several of its product inspection systems at the Interphex trade show in New York City (April 16-18). More specifically, the company showcased pharmaceutical and biotech inspection technology.

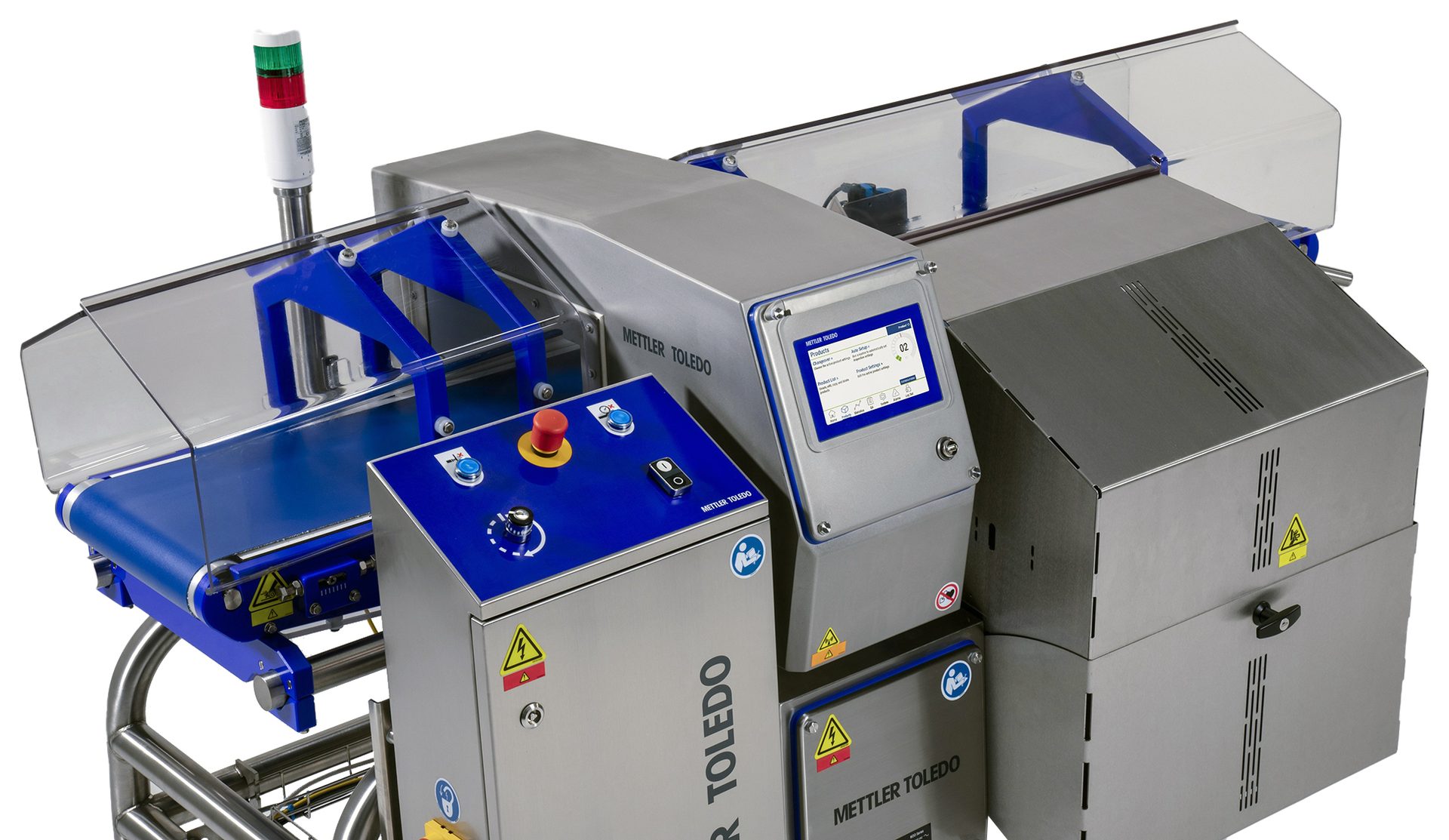

One example is Mettler-Toledo’s CV35 “combination system,” which integrates a checkweigher with vision inspection. “This combo solution detects and rejects under- and overweight packages to ensure legal weight requirements are met and reduce product giveaway, while offering a variety of label inspection capabilities including verification that the weight printed on each label matches the weight of each product,” the company notes.

Meanwhile, Antares Vision Group recently introduced a noninvasive, inline pressure measurement system providing reliable, high-speed inspection for beverages in glass and plastic bottles. For the wine sector, the company’s PCS 700-IoT system enables in-line oxygen measurement to evaluate the efficiency of the inertization process after bottle closing.

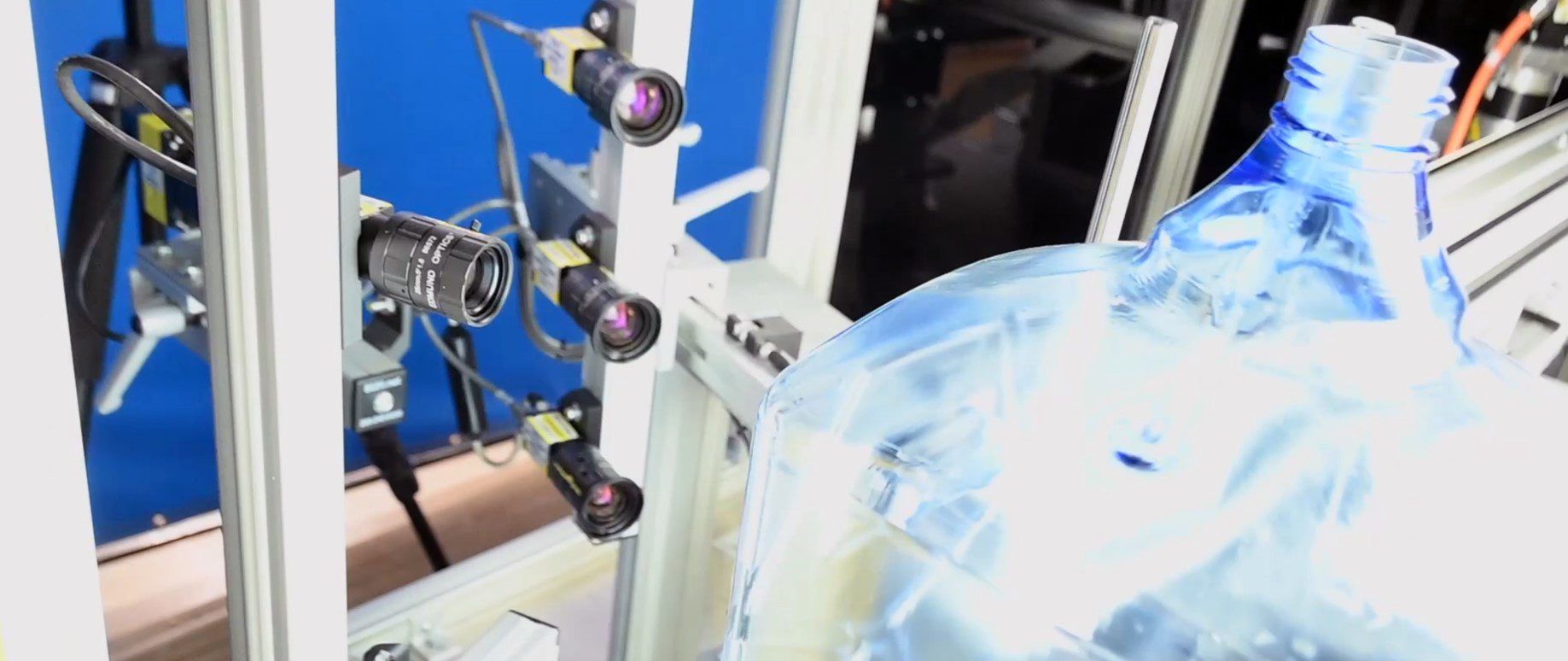

Norwalt’s Vue Inspection System integrates standardized vision components with custom-made elements and deep learning tools.

Courtesy of Norwalt

Ishida has provided a leak detection system for a product that might not immediately come to mind as requiring package inspection: tortillas. However, the inspection equipment plays a critical role. The tortillas are made without preservatives but have a shelf life of six months thanks to their protective carbon dioxide and nitrogen atmospheres — provided that the thermoformed packaging is absolutely airtight.

Not to be outdone, Norwalt has engineered one of its most sophisticated bottle vision inspection systems to date. The company’s Vue Inspection System integrates standardized vision components with custom-made elements and deep learning tools. The system is able to monitor gauging defects as miniscule as 10 thousandths of an inch on a translucent surface, a mission accomplished using shape transformation on the sloped areas of bottles.

Learn more about these exciting new developments in inspection, detection and vision.

Mettler-Toledo Showcases Product Inspection Systems at Interphex

Mettler-Toledo Product Inspection Group exhibited a wide variety of their world-class pharmaceutical and biotech inspection technology in booth #2361 at Interphex, held at the Javits Center in New York City, April 16-18, 2024.

These x-ray systems, metal detectors, checkweighers and vision systems help customers protect product safety and comply with regulatory requirements while improving process efficiencies.

“Of course, our primary goal is to help product manufacturers and contract packers eliminate any foreign material contamination and minimize the chance of improperly filled or mislabeled packages, but we do so much more to help them succeed,” said Robert S. Conrad, Sales Director – Pharma at Mettler-Toledo. “Our easy-to-use automated systems minimize labor requirements and allow new operators to come up to speed quickly. Electronic connectivity and data management tools like our ProdX software seamlessly transmit and compile digital documentation. And our large network of knowledgeable service technicians further contributes to the best system performance and uptime.”

READ MORE

This year at Interphex, Mettler-Toledo showcased their CV35 ‘combination’ system, which integrates a C35 AdvancedLine checkweigher with vision inspection. This combo solution detects and rejects under- and overweight packages to ensure legal weight requirements are met and reduce product giveaway, while offering a variety of label inspection capabilities including verification that the weight printed on each label matches the weight of each product.

Additionally, Metter-Toledo displayed their newest x-ray system, the affordable X12 for small- and medium-sized packaged products. In addition to detecting hard-to-find physical contaminants including glass and metal, the X12 can perform a variety of product integrity checks, such as correct product placement within a package, to further ensure product quality.

The M31R, Mettler-Toledo’s newest metal detector, was also on exhibit at the show. This entry-level system features their advanced SENSE™ software, which utilizes sophisticated algorithms to deliver improved detection sensitivity with minimal false rejects.

Another metal detector on display was the Tablex-PRO for inspecting bulk tablets and capsules. With an easy-to-use color touchscreen, failsafe reject design and reject confirmation, the Tablex-PRO features ultra-high frequency operation and enhanced noise and vibration immunity to achieve exceptional detection sensitivity.

Mettler-Toledo’s ProdX™ software, available on virtually all their inspection systems, was also showcased at Interphex. By enabling customers to monitor their equipment remotely and easily collect, save, search and share data, ProdX improves product safety and increases production efficiencies while ensuring regulatory compliance.

For more information about Mettler-Toledo’s product inspection equipment, visit mt.com/pi.

The M31R, Mettler-Toledo’s newest metal detector, utilizes sophisticated algorithms to deliver improved detection sensitivity with minimal false rejects.

Courtesy of Mettler-Toledo

COLLAPSE ARTICLE ABOVE

Antares Vision Group Introduces Inline Pressure Measurement System for Beverages

Antares Vision Group, a technological partner in digitalization of products and supply chains for companies and institutions, and leader in traceability and inspection for quality control, has introduced a noninvasive, inline pressure measurement system providing reliable, high-speed inspection for beverages in glass and plastic bottles.

Applicable for all transparent and semi-transparent bottles, the company’s PCS700-IOT utilizes advanced laser spectroscopy technology to precisely determine whether a container headspace has appropriate pressure levels. Among other benefits, the result is accurate, non-destructive leak detection and process optimization.

Through a technique called Tunable Diode Laser Absorption Spectroscopy (TDLAS), the PCS700-IOT analyzes specific molecules in their gaseous state — in particular, their ability to absorb light at certain telltale wavelengths. The laser beam passes through the bottles in the product-free headspace.

READ MORE

For carbonated beverages like seltzer, soda and beer, this enables CO2 levels and pressure concentration to be measured quickly and accurately, revealing whether a leak or micro-leak is occurring. Leak-determining pressure inspection also can be performed on nitrogen-dosed products such as water and teas, as well as hot-filled beverages including various juices. For the wine sector, PCS 700-IoT enables the in-line oxygen measurement to evaluate the efficiency of inertization process after bottle closing.

Crucially, the PCS700-IOT is a smart system: the unit can monitor not only total pressure, but an average across complete or partial product runs. These metrics are presented in real-time on a user-friendly dashboard, making for expedient and exacting assessment of products deviating from the norm. Critically, the system performs these tasks without necessitating changes to existing production line setups.

Antares Vision Group’s PCS700-IOT offers several advantages over the acoustic technologies widely used in the beverage market. For starters, detection via laser spectroscopy is significantly more precise, meaning false rejects are substantially diminished. Perhaps even more importantly, though, is the system’s ability to inspect containers inline without production slowdown, as well as its consistency regardless the type of cap used.

A strong example of the PCS700-IOT’s value is its inline utilization in beer bottling operations. In this scenario, laser spectroscopy inspection can be conducted immediately following pasteurization. This strategic positioning reliably intercepts any leaks or micro-leaks due to the heating and subsequent cooling of the container during pasteurization, as well as any micro-cracks in the bottle mouth. Bottles with pressure below a certain level are automatically rejected, with persistent pressure level monitoring allowing operators to adjust for minor deviations before they become major, line-stopping issues.

The PCS 700 IoT, like all Antares Vision Group inspection machines, is part of the company’s DIAMIND Line suite.

Antares Vision Group’s PCS700-IOT offers several advantages over the acoustic technologies widely used in the beverage market. For example, detection via laser spectroscopy is significantly more precise, meaning false rejects are substantially diminished.

Courtesy of Antares Vision Group

Antares Vision Group’s PCS700-IOT offers several advantages over the acoustic technologies widely used in the beverage market. For example, detection via laser spectroscopy is significantly more precise, meaning false rejects are substantially diminished.

Courtesy of Antares Vision Group

COLLAPSE ARTICLE ABOVE

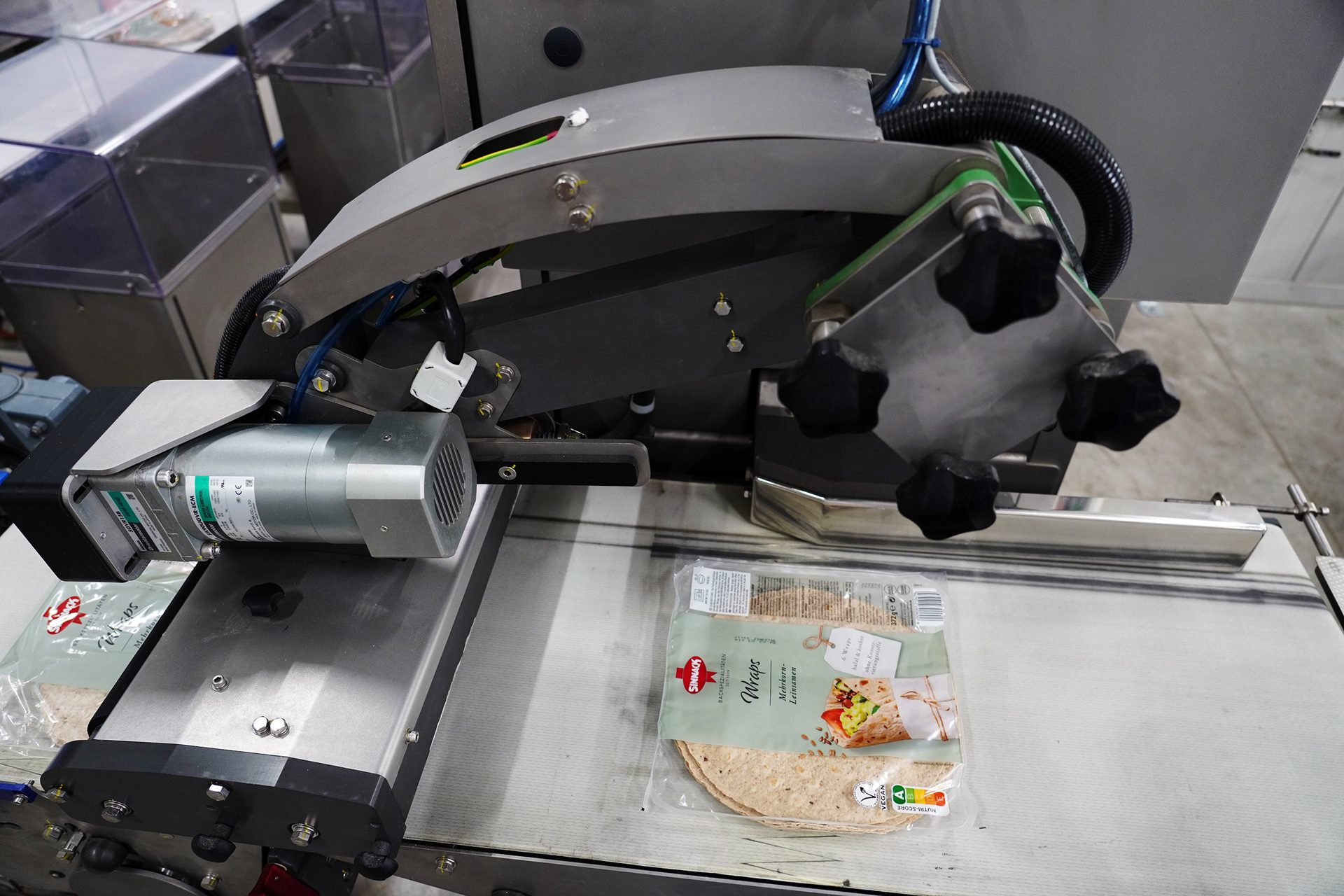

Ishida Leak Detection System Provides Crucial Quality Checks for Tortilla Pro

The installation of an Ishida AirScan leak detection system at Sinnack Snacks, Germany’s only large-scale bakery to focus on tortillas, has enabled the company to automate its end-of-line packing process, while ensuring that its quality control procedures are able to keep pace with the increased throughput.

The Ishida solution can inspect as many as 2,500 packs per hour, reliably detecting leaks as small as 0.5mm to ensure the integrity of the protective atmosphere packaging.

Sinnack Snacks produces wheat, multigrain and protein tortillas in diameters of 20, 25 and 30cm, which are sold in packs of 6, 8 and 12. The fresh products are made without preservatives but have a shelf life of six months thanks to their protective carbon dioxide and nitrogen atmospheres – provided that the thermoformed packaging is absolutely airtight.

READ MORE

However, bits of the tortillas can sometimes get into the seals during the packing process and cause leaks. Other potential sources of defects include wrinkles in the seal. The stage of the process that comes after the films are changed on the thermoforming machinery is also critical. If the films overlap at this point, the packaging may not be sealed correctly.

For these reasons, Sinnack Snacks has always made sure to test the integrity of its protective atmospheres. The company previously used a system with a vacuum chamber to check the entire content of fully packed boxes for leaks.

“This was a very time-consuming quality control exercise, because when a reject was found, we didn't know first which of the packs was the one with the leak,” said managing partner Jana Sinnack. “Not only that, but quality control was also not 100% reliable.”

With growing sales of its tortillas, Sinnack Snacks needed to automate the end-of-line packing on one of its lines and this required a new means of leak testing. “We were looking for an in-line system that was capable of checking every single pack at high speed and picking out any rejects,” Sinnack explains.

The Ishida solution is the company’s fully automated AirScan, which uses a laser module to detect the specific vibrations caused by leaking carbon dioxide molecules. The machine can reliably detect leaks measuring just 0.5 mm. As a result, users not only gain the security of knowing that leaks will be found but can also cut down on material costs because the inspection process exerts minimal pressure and is therefore non-destructive.

In addition, the Ishida AirScan is compact in size and can easily be integrated into existing packing lines. Another factor in Sinnack Snacks' decision was the fact that Ishida had already successfully deployed the system in a similar application in the bakery industry.

The Ishida AirScan has enabled quality assurance at Sinnack Snacks to reach a new level. Up to 2,500 packs can be inspected per hour, with the system checking both the top and bottom sides for escaping carbon dioxide. The leak detector compiles all the process data in reports that can then be viewed. As Sinnack explains, “We scrutinize any rejected products in minute detail, because identifying the causes of problems ultimately makes our processes more efficient.”

The success of the first machine has led Sinnack Snacks to install Ishida AirScan systems on two further lines as part of its ongoing automation process. Ishida customized the machines to suit the company's specific requirements in terms of pack dimensions and its reject system.

The installation of an Ishida AirScan leak detection system at Sinnack Snacks, Germany’s only large-scale bakery to focus on tortillas, has enabled the company to automate its end-of-line packing process.

Courtesy of Ishida

COLLAPSE ARTICLE ABOVE

Norwalt Introduces Innovative Bottle Inspection System

Norwalt, a specialist in custom-built automation and line integration machinery for complex manufacturing applications, has engineered one of its most sophisticated bottle vision inspection systems to date. The company’s Vue Inspection System integrates standardized vision components with custom-made elements and deep learning tools.

Norwalt’s new machine has one overarching, pioneering benefit: its ability to monitor gauging defects as miniscule as 10 thousandths of an inch on a translucent surface. It accomplishes this by using shape transformation on the sloped areas of bottles.

READ MORE

The Vue Inspection System was designed and engineered in Norwalt’s dedicated Vision Systems Lab. Outfitted to accommodate up to eight programmers simultaneously, the state-of-the-art facility incorporates next-gen visual inspection and deep learning tools, including emerging Artificial Intelligence (AI) vision innovations and 3D profiling. Norwalt also integrates advanced optical character recognition (OCR) and verification via optical character verification (OCV).

With the Vision Systems Lab, Norwalt also designs machines that utilize closed-loop data for machine adjustments and continuous production improvements. The lab also provides gauge repeatability and reproducibility (GR&R), and Type One studies when needed, as well as full evaluation of a project’s field oriented control (FOC).

“Norwalt is increasingly committed to enhancing our vision capabilities,” said Keith Harman, Director of Business Development & Technical Sales for Norwalt. “As industry demand increases, we’re seeing an increasing number of requests for our advanced and more sophisticated systems.”

To learn more about Norwalt, please visit norwalt.com.