Focus: Parts/components

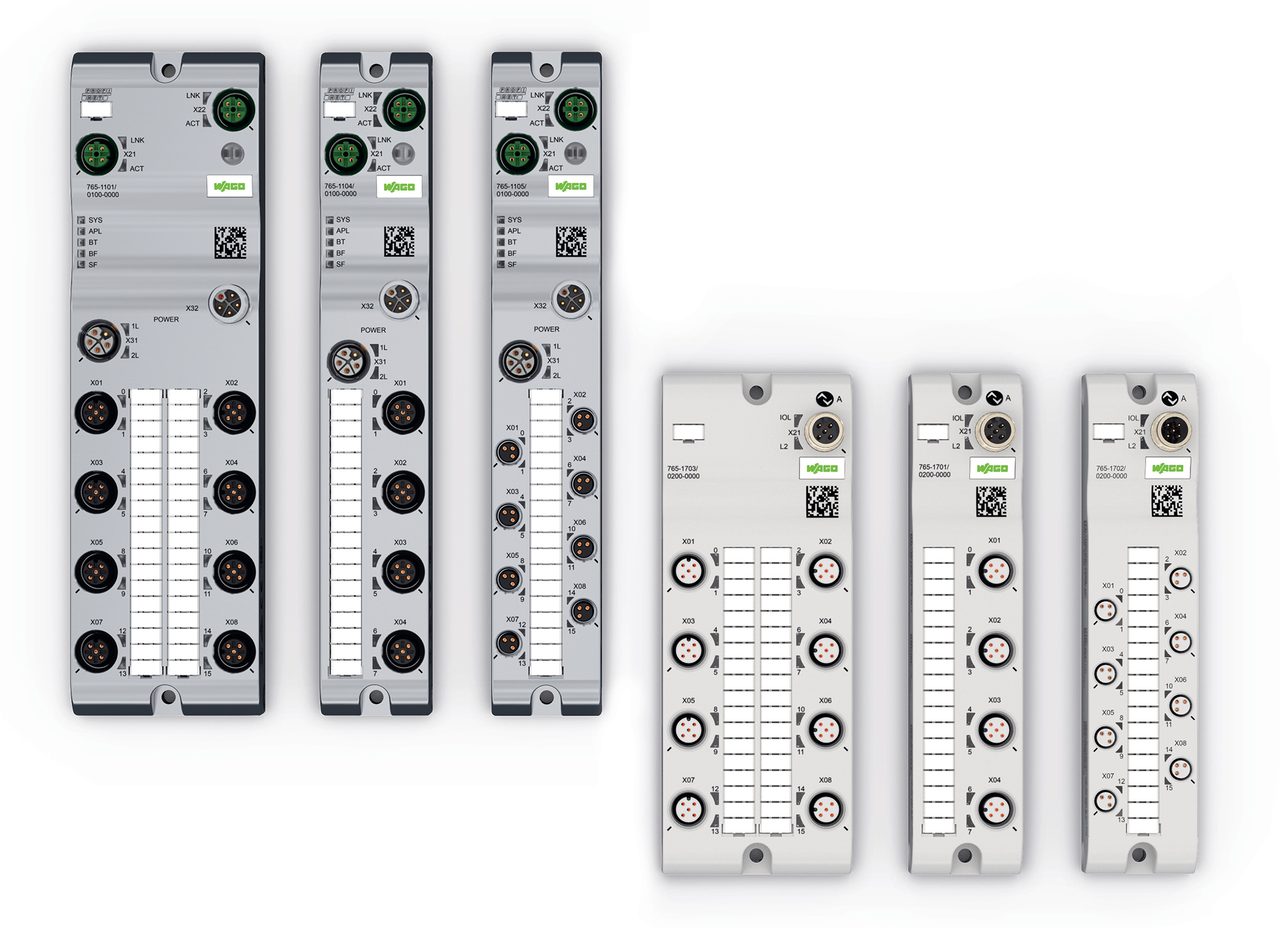

WAGO is Expanding its IP67 rated I/O System Field

The fully encapsulated metal housing fieldbus modules now include components that support EtherNet/IP and EtherCAT protocols and offer configurable I/O as well as IO-Link master ports. With a built-in bluetooth interface, users can configure these modules for commissioning and maintenance procedures while in the line of site of their plant floor equipment. For IIoT and SCADA applications, users can leverage OPC UA protocol for data monitoring and control. The non-encapsulated lightweight modules are IO-Link hubs for versatile connection to an IO-Link Master. These hubs come in either 8 or 16 configurable DIO ports and each channel is configurable for a 24 VDC digital input or output rated at 2 amps per channel. Current and voltage levels can be recorded and evaluated, and overload limits and alarms can be set for each channel, providing system reliability.

::::: wago.com

Courtesy of Wago

Focus: Machinery

Harpak-ULMA Artic SS Brings Multi-Side-Seal Capabilities to Medical, Bakery, Meat and Dairy Packaging

Harpak-ULMA offers a new Artic Side Seal packaging system featuring new multi-side-seal capabilities for medical, bakery, meat, and dairy applications. The company also introduced the availability of Rockwell Automation controls for its Vertical VTC 800 series hygienic design vertical packaging machines. Both announcements represent an expansion of Harpak-ULMA's North American flow wrap and vertical solutions portfolio as driven by customer requests. The Artic Side Seal (SS) packaging system can produce multiple side-seal formats, including both zippered and strip resealable, as well as 3-sided non-resealable formats, shrink films, and modified atmosphere capabilities. The Artic SS produces non-hermetic or hermetically sealed packs. It relies on a simplified longitudinal side-sealing system for the side seal and features a long dwell sealing head for the cross seal. The solution's market-leading total cost of ownership (TCO) is attributable to competitive upfront installation costs combined with lower lifetime maintenance requirements associated with its design simplicity. In addition, the Artic SS offers an attractive alternative to traditional fin-sealed flow wrap packaging. Fin-sealed packages result in divided panels on one side and therefore a somewhat smaller printable area, whereas side-seal allows both sides of the packaging to be fully utilized.

Harpak-ULMA also announced the upcoming availability of Rockwell Automation (RA) controls for its VTC 840 (VFFS) vertical packaging platforms in 2022. The embedded smart, connected Rockwell Automation controls technologies support numerous advanced capabilities, including PTC's Vuforia Augmented Reality (AR) software suite. AR technologies enable remote maintenance and diagnostics, visual work instructions and training, and advanced performance monitoring, such as Harpak-ULMA's embedded OEE Application. The OEE app automatically calculates, monitors (including remotely), and reports packaging line performance to benchmark machine performance.

::::: harpak-ulma.com

Courtesy of Business Wire

WWP Beauty Launches Sustainable, Refillable Stock Packaging Collection

WWP Beauty has launched its new Refill Revolution collection featuring a series of refillable packaging solutions that reduce carbon emissions, promote a more circular design system and spark joy for environmentally conscious brands and consumers through reduced waste and packaging. Each of the components in this collection features a refillable design with measured carbon emissions reduction targeting different categories of beauty.

Refill Revolution Airless Pens: Features touchless, sensorial and integrated applicators that reduce carbon emissions by up to 60% after three refills. The applicator options include a cooling metal roller ball applicator for spot treatments and eye serums, a triple micro rollerball applicator for targeted eye and lip treatments, and an oval brush applicator for concealers and liquid complexion products. The smart, low-profile design of these pens makes them an easy refill system to integrate into an existing cosmetic line.

Refill Revolution Multi-Use Face Stick: A patented, award-winning design that produces 72% fewer GHG emissions after three refills when compared to a standard, non-refillable face stick of the same size and shape. Additionally, this component features a multipurpose, direct-apply design that produces minimal refill waste and can be made with PCR content. A great option for color cosmetic and skincare formulations.

Refill Revolution Multi-Use Body Stick: A patent-pending, award-winning design featuring an intuitive, easy-to-use refillable system with a mono-material refill cartridge and the option to add PCR content. This component reduces GHG emissions by up to 71% after three refills and is an ideal option for body care, personal care and hygiene products, and skincare.

Refill Revolution Powered Up Pump: A keepsake design that preserves formula integrity is easy to refill and has the option to add PCR content for increased sustainability claims. Can be used for color cosmetics, skincare, and hair care products.

Refill Revolution Refill & Go Bottle: A portable, compact design that can be easily refilled and taken on the go. With this component, the options for refilling are endless, and it can be used for a wide range of cream or gel-based formulas in color cosmetics, skincare, body care, personal care and hair care.

::::: wwpbeauty.com

Courtesy of WWP Beauty

Vacuum Packaging in a New Dimension

The compact model in hygienic design is a perfect all-rounder for vertical packaging of large products such as ham, pieces of meat or other large and loose containers. Numerous strong performance features not only offer added value for food processing companies but also make the VSM Bulky a resilient and at the same time efficient component in the production process.

The new packaging machine with manual bagging evacuates, gas flushes, and seals vertically in a very confined space. It is particularly suitable for productions with frequently changing product batches or for applications where a high degree of flexibility is required. Vertical packaging enables vacuuming and gas flushing from above in bags directly within transport boxes or E2 crates, cartons or drums, which means that even large packs can be packaged easily and reliably.

High packaging quality and efficiency: The extra-wide vacuum station with double-sided impulse sealing ensures reliable wrinkle-free sealing even with large formats and even with moist pouches. "In addition to the reliable vacuum, the wrinkle-free sealing seam and the double-sided impulse sealing are decisive factors with regard to packaging quality, product protection and shelf-life," says Julia Mayer, product engineer at MBM.

Other advantages that first-time users particularly appreciate include a fast vacuum time and the fact that the VSM Bulky is ready to start immediately at the touch of a button. "Separate preheating times are eliminated because we do not use a permanently heated sealing bar. This means that the packaging machine contributes significantly to higher productivity. This is particularly noticeable with frequently changing batches," adds Mayer.

Thanks to the proven VSM technology, the entire evacuation process takes place under normal atmospheric pressure — without a vacuum chamber. This guarantees a high-quality vacuum that is gentle on the product, which is particularly advantageous for sensitive product structures.

Flexibility in many respects: The space-saving, slim design allows the versatile VSM Bulky to be used in almost any work environment. The innovative model is also mounted on castors and can simply be pushed wherever it is needed. However, should modifications be necessary due to specific requirements, MBM offers the possibility to make individual adaptations to the standard machine thanks to its high vertical range of manufacture and comprehensive expertise in special machine construction.

Another plus: The VSM Bulky has two gas connections so that two different types of gas can be connected for gassed packs with modified atmosphere (MAP packs). Individual programs with the different gas types and vacuuming times can be stored in the system for this purpose.

Finally, there are virtually no limits to the flexible multi-talent in terms of the range of products that can be processed. The extra-long sealing bar (max. sealing length 1,100 mm) even accommodates packaging of very large products and loose packs. Hams, roasts, and various pieces of meat, sausage, fish and cheese can be packed safely without any problems. There are also numerous possible applications in the pharmaceutical and non-food sectors.

Easy operation, cleaning and maintenance: In the development of its brand new all-rounder, MBM placed great emphasis not only on optimum performance and machine quality but also on hygiene, ergonomics and safe working with the machine.

For example, the VSM Bulky has a hygienic design based on EHEDG [European Hygienic Engineering & Design Group] guidelines and can therefore be used in sensitive application areas such as the food industry. The integrated cleaning program for rinsing the suction nozzles and hoses also ensures ideal and effective cleaning of the machine.

The machine is controlled safely and intuitively via the KTP 700 touch panel with a total of ten program positions. With two-hand operation and protective covers, MBM naturally meets the highest safety standards.

In addition, as with all VSM systems, MBM customers benefit from a high level of ease of maintenance. Common wear parts can be easily replaced without the need for a service technician, and spare parts are quickly available.

Optionally, the VSM Bulky can be equipped with a roller conveyor as well as a bag insertion aid for quick insertion of the bag into cartons or boxes.

::::: mbm-innovations.com

Courtesy of MBM innovations GmbH

Airnov Showcases Debuts New Brand and Products at Supplyside

The new canister does away with labels, inks, adhesives, and varnishes by utilizing high-power laser technology to mark canisters through a photochemical effect that results in a permanent, legible marking. In addition to increasing product safety by eliminating extraneous materials, the new marking system reduces waste and the carbon footprint of Airnov’s canister line. At SupplySide West, Airnov will showcase the new 2- and 3-gram versions of the laser marked canister, scheduled for launch in Q3 of 2022.

Another tool in Airnov’s arsenal to protect and enhance nutraceutical products is the Aroma-Can scented canister. This innovative canister uses natural flavors molded into a plastic canister for high-speed insertion. The flavors can cover unwanted odors in products such as fish oil or enhance the user experience by adding scents to vitamins and probiotics. This year saw the addition of mint and strawberry to the core flavors of orange, lemon and vanilla.

Airnov’s EQius equilibrium stabilizers keep natural and herbal products safe by acting as a desiccant when the humidity is high and a humectant when the humidity is low. This innovative solution maintains the relative humidity inside customer packaging for products that can become damaged if the internal packaging environment is too dry or moldy if the humidity is too high. The pre-conditioned canisters and packets come in a range of sizes and humidity levels to meet your product’s specific needs.

::::: pressreleasefinder.com

Courtesy of of Airmov