Smarter Ecommerce

Packaging

From quality labs allowing shippers to analyze label properties in advance, to custom-sized packaging that reduces waste, these companies are helping online retailers meet packaging challenges head-on.

Ecommerce

Packaging

Smarter Ecommerce

Packaging

From quality labs allowing shippers to analyze label properties in advance, to custom-sized packaging that reduces waste, these companies are helping online retailers meet packaging challenges head-on.

By Brad Addington

According to Statista, ecommerce revenue is expected to grow by 51% in the United States between 2024 and 2029, with revenue expected to hit $1.2 trillion in 2024 and climb to $1.8 trillion in 2029.

With this sustained growth comes increased demand for ecommerce packaging solutions, and this year has seen no shortage of companies offering innovative packaging options for online retailers.

To support ecommerce, R.R. Donnelley & Sons Company (RRD) announced earlier this year that it was expanding its labels production capacity with the installation of four new presses in facilities across the United States. The presses will deliver faster total throughput, enhancing efficiency and flexibility to support clients’ diversified needs.

RRD also announced the opening a new state-of-the-art label quality lab to support clients by thoroughly evaluating and developing products ahead of production.

Also this year, Packsize’s Greg Caldwell explained how on-demand boxes can address ecommerce and sustainability challenges.

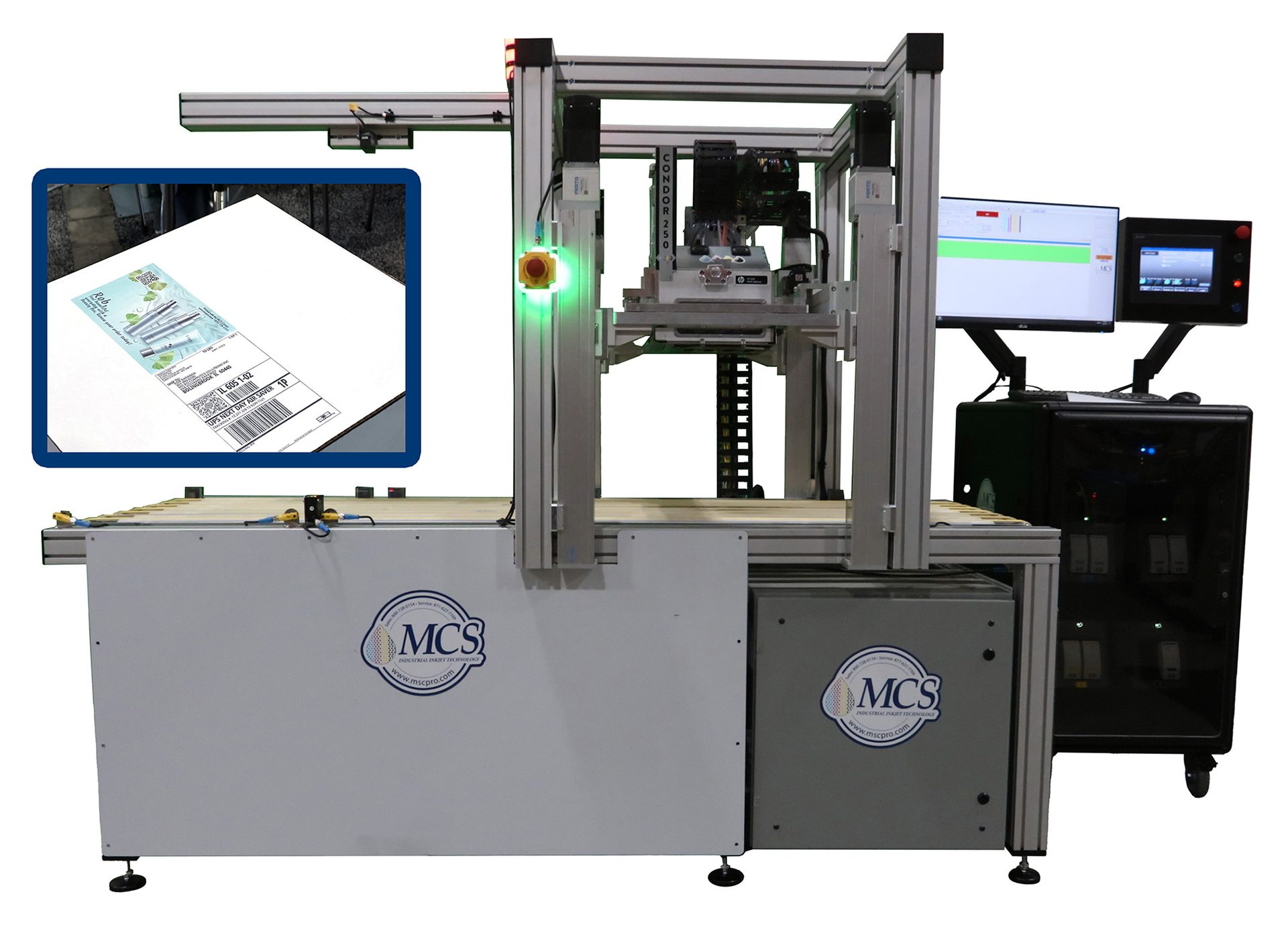

And most recently, MCS Inc. President David Loos made the case that, thanks to high-speed inkjet systems, ecommerce sellers now have the option to ditch adhesive labels and print directly on secondary packaging, including on bags and corrugated boxes.

Read the stories below to find out how companies like RRD, Packsize and MCS Inc. are transforming ecommerce packaging.

ADVERTISEMENT

RRD Expands Label Capacity to Enhance Efficiency and Support Ecommerce

R.R. Donnelley & Sons Company (RRD), a leading global provider of marketing, packaging, print, and supply chain solutions, announced in April that it is expanding its labels production capacity with the installation of four new presses in ISO 9001:2015 certified facilities across the U.S.

The presses will deliver faster total throughput, enhancing efficiency and flexibility to support clients’ diversified needs. All presses are expected to be fully operational by midyear 2024.

READ MORE

- Two ETI flexo presses will be outfitted to vertically integrate face and liners paper to create pressure sensitive label stock.

- One Mark Andy P9 flexo press will produce variable image labels.

- One Mark Andy digital hybrid press will be installed to allow RRD to serve clients in a more rapid environment to address their ever-changing needs.

This expansion comes amid a booming ecommerce market. According to Statista, ecommerce revenue is expected to grow by 51% in the U.S. between 2024 and 2029, with revenue expected to surpass one trillion U.S. dollars. With this sustained growth comes increased demand for variable imaged labels, enabling RRD to provide end-to-end solutions to a range of clients of many sizes and locations.

“The market is constantly changing, and with our highly connected, global network we remain committed to investing in the right technology to meet our clients’ evolving label needs,” said Lisa Pruett, President, Packaging and Labels Segment at RRD. “Speed to market, high-quality products, and strong partnerships are important to our clients — we continue to keep those priorities top of mind.”

Additionally, RRD is opening a new state-of-the-art label quality lab to support clients by thoroughly evaluating and developing products ahead of production. The center will offer paper analysis, adhesive properties testing, accelerated aging and exposure analysis, printability, and most other testing procedures related to the label industry. The lab is expected to be operational by early May 2024.

These investments emphasize RRD’s continued focus on providing its clients with a variety of cost effective, high-quality labels that leverage the latest technology for speed and efficiency. Find more information on RRD’s label offerings here.

Courtesy of RRD

COLLAPSE ARTICLE ABOVE

The Challenges of Ecommerce Packaging and Sustainability

In the era of online shopping, where convenience and speed are paramount, ecommerce has grown at an exponential rate. However, this convenience often comes at the expense of the environment, and, with environmental awareness on the rise, businesses are met with a challenge of sustainability and meeting customer demand. Right-sized, on-demand packaging solutions empower companies to optimize their processes, reducing waste and minimizing their carbon footprint. In this article, we examine the challenges faced by the packaging industry in the ecommerce and sustainability era and how on-demand packaging should be the new status quo.

READ MORE

Ecommerce Growth and the Benefits of On-Demand Packaging

Ecommerce growth is undeniable, and this trend has generated massive amounts of packaging materials to protect products during transit. Traditional, oversized boxes, along with plastic fillers and bubble wrap, have become the norm. This approach not only results in the squandering of valuable resources but also leads to an excessive carbon footprint due to inefficient shipping.

Sustainable packaging solutions align with the needs of modern ecommerce to optimize the balance between efficiency and sustainability. On-demand packaging solutions are a revolutionary approach involving the creation of custom-sized boxes that perfectly fit the products being shipped. By eliminating excess void fillers and choosing the right box size, it minimizes the need for extra packaging materials, thus reducing waste. The concept ensures that a minimum amount of packaging is used, directly contributing to environmental conservation.

The custom-sized packaging is generated using proprietary machines. These machines are highly automated and can be integrated into an ecommerce fulfillment center’s existing operations. The benefits of on-demand packaging are manifold. First, it significantly reduces the carbon footprint of shipping. Less material is used, and smaller boxes occupy less space, translating to more efficient transportation and reducing fuel consumption. Additionally, fewer deliveries may be needed due to the optimization of package sizes.

Besides the environmental benefits, on-demand packaging solutions have a positive impact on ecommerce companies’ bottom line. Businesses save on production costs by reducing the need for extra packaging materials. With that, smaller boxes can lead to reduced shipping costs, contributing to overall cost savings. This win-win scenario demonstrates how sustainable solutions can be economically beneficial for businesses. Sustainability and profitability are not mutually exclusive.

A crucial aspect of right-sized packaging is sustainability. This packaging solution is part of the circular economy. The boxes themselves are made from recyclable cardboard, and the machinery is designed for durability and longevity. This is just another way that on-demand packaging allows for waste reduction by reducing, reusing and recycling.

Conclusion

The world is becoming more and more aware of the urgent need for sustainability, and right-sized, on-demand packaging solutions help to create environmentally friendly practices and set an example for the entire ecommerce industry. This innovative approach to packaging not only addresses the issue of waste but also positively impacts the bottom line of businesses involved in ecommerce. By creating custom-sized, eco-friendly packaging, businesses and customers alike can transform the way they think about packaging and sustainability.

The Packsize X5 produces ready-to-pack, right-sized erected boxes at an industry-leading speed of up to 600 boxes per hour. The X5 machine significantly enhances ecommerce providers’ and manufacturers’ ability to meet customer demand.

Courtesy of Packsize

The Packsize X5 produces ready-to-pack, right-sized erected boxes at an industry-leading speed of up to 600 boxes per hour. The X5 machine significantly enhances ecommerce providers’ and manufacturers’ ability to meet customer demand.

Courtesy of Packsize

COLLAPSE ARTICLE ABOVE

Skipping the Label: High-Speed, Direct-to-Packaging Printing Comes of Age

Businesses that rely heavily on corrugated boxes or bags as secondary packaging, including ecommerce sellers, retailers, and manufacturing companies, have been actively seeking alternatives to standard adhesive shipping labels.

Printed adhesive labels are primarily used for variable data such as address, tracking codes, product identification, and instructions for use. Labels can also include logos, brand messaging, and other promotional elements as well.

However, labels have significant disadvantages, including being an enormous source of environmental waste. Large volumes of paper, films, adhesives, printing plates, solvents and chemicals are typically left over as byproducts of the label production process. Most adhesive labels are not recyclable and can contaminate the box or bag such that it is no longer recyclable.

To mitigate these environmental impacts, shippers and ecommerce retailers are increasingly exploring alternative solutions that are more sustainable. This includes eliminating the need for a traditional adhesive label by printing directly on secondary packaging using high-speed inkjet systems.

READ MORE

The technology, which is already utilized in the mail manufacturing industry to produce personalized mass mailings in extremely high volumes, eliminates the primary barrier to direct printing — namely, the ability to print in full color, with variable information, at the extremely high speeds required.

A Blank Canvas for Promotion

Secondary packaging plays a significant role in marketing and branding strategies. In addition to safeguarding primary packaging, it provides a golden opportunity for companies to showcase their brand identity, logos, slogans, and promotional messages. By carefully considering the secondary packaging design and shipping methods, ecommerce retailers and shippers can differentiate themselves from their competitors and increase the likelihood of customers choosing their products.

This applies, of course, to the traditional adhesive labels used on corrugated boxes and bags.

However, given the volume of packages shipped, there is an industry-wide mandate to reduce the environmental impact along the entire chain. As sustainability becomes more critical, corporate leaders like Amazon are looking for ways to significantly improve their mail and packaging efficiency while reducing their environmental footprint.

According to the Nov. 8, 2021, article posted on Packaging World’s website, “Amazon Invests in Fit-to-Size Box Making Equipment Company,” by Anne Marie Mohan, Amazon is investing in CMC Machinery, a company with technology that makes custom-sized boxes that eliminate the need for single-use plastic packaging. That is, the technology allows for customized boxes based on the size and type of item to reduce the amount of air (unused space) in the boxes.

This concept spurred MCS Inc., a company that designs, manufactures, sells, and supports high-speed industrial inkjet imaging systems for the mail manufacturing industry, to conduct tests on packaging equipment at its facility to explore the idea of incorporating advertising messaging in process color directly on the packaging.

A leading supplier of high-speed mail manufacturing equipment since 1989, MCS’s inkjet and tracking products are designed and manufactured in the United States. MCS equipment has been used for many mission-critical mailings, including two U.S. Censuses and many vote-by-mail elections.

“We are already getting quite a few inquiries from logistics and fulfillment companies asking about images that can be printed directly on boxes and bags,” says MCS President David Loos.

Direct Printing of Corrugated

Corrugated board is produced by combining various papers together in the form of paper layers. These layers are called liners and fluting (the fluting being formed to create a specific profile). The liners can be pre-printed with standard messaging before it is glued to the medium. This is a cost-effective method for high-volume production.

After the corrugated board is converted to boxes, “High-speed, direct-to-packaging inkjet printers could then be used in defined locations on the box to deliver customized promotional messages such as a special offer, or an announcement about a new store opening in a region,” explains Loos.

Direct Printing of Custom Bags

Loos says that MCS was approached last year for a solution that would print trackable variable barcodes directly on shipping bags. Many larger bag suppliers invest in high-tech manufacturing equipment to offer cutting-edge bag solutions, including modern bag designs in many shapes, variations, and types of substrates. The bags are used by ecommerce sites for shipping and by online retailers that offer home delivery services.

For high-speed printing, roll-feed flexographic printers are utilized. The paper rolls are then cut into sheets at approximately the same speed. The concern was whether direct-to-bag printing systems could keep up. The average inkjet printer operates at a speed of 105 to 500 feet per minute. However, MCS has printers that can reach speeds of up to 1,000 feet per minute.

“We print on a wide web at very high speeds and there are very few [direct print inkjet] machines that can run at a thousand feet per minute and print the high-quality tracking codes at that speed,” says Loos.

Although the bag is printed on a flexographic printer, space is available on the press to add an inkjet printer for direct printing of tracking codes and “just about anything else you can think of,” according to Loos.

“Instead of a label going on that affects the cost and affects the recyclability of the product, we can now digitally print that unique code directly on the bag using the MCS printer,” says Loos. “We can print anything the customer wants, including notifications about store openings in their area, special offers, links to sales or other sites, or other promotional messages.”

The equipment used is one of the fastest inkjet printers in the industry — the MCS Hayabusa Inkjet — which delivers print widths from 4.25 to 34 inches. MCS offers other direct-to-packaging alternatives at different speeds and price points.

Loos believes that direct printing to bags or boxes will have many applications in the future now that the primary barrier — speed — is no longer an issue.

MCS Box Printer

Courtesy of MCS Inc.

MCS Printheads

Courtesy of MCS Inc.