Aligning Convenience and Circularity

For brands aiming to boost both sustainability and consumer appeal, today’s flexible packaging closure designs can assist in circularity objectives while continuing to deliver the convenience and functionality that help build brand loyalty.

By Todd Meussling, Fresh-Lock® Director of Business Development and Sustainability

Flexible packaging often combines multiple components, including films, barriers, inks, finishes, and closures, and all these features must work together to meet consumer expectations. Creating a sustainable pouch adds another layer of complexity, as all the components must align not only functionally but also in their sustainability profile.

Fortunately, advancements in packaging materials have made it easier than ever to produce pouches where every element — including closures — supports sustainability goals. While films have received much attention in this area, closure innovations have quietly kept pace, offering more options than many brand managers and packaging engineers may realize.

For brands aiming to boost both sustainability and consumer appeal, today’s flexible packaging closure designs can assist in circularity objectives while continuing to deliver the convenience and functionality that help build brand loyalty.

ADVERTISEMENT

Why Use Closures on Flexible Packaging?

Reclosable packaging isn’t just a consumer preference — it’s a value-add that offers product containment, protection, and convenience for the consumer.

In the United States alone, more than one-third of all food goes to waste. Reclosable packaging helps to combat this loss after initial opening, allowing consumers to enjoy their product over multiple servings without the need for extra repackaging.

Reclosable flexible packaging also offers a degree of reusable functionality even where return-and-refill infrastructure is unavailable. Pouches that feature a press-to-close zipper or slider makes packaging easy to open and securely reclose, enhancing accessibility and storage convenience at home, at work, or on the go. By prioritizing the user experience in this way, CPG brands can strengthen connections with their consumer audience.

"Closures help keep products in their original packaging longer, extending brand visibility after purchase. This repeated exposure reinforces brand recognition and trust, increasing the likelihood of repeat purchases."

— Todd Meussling, Fresh-Lock® Director of Business Development and Sustainability

Closures also help keep products in their original packaging longer, extending brand visibility after purchase. This repeated exposure reinforces brand recognition and trust, increasing the likelihood of repeat purchases.

Closures That Close the Sustainability Gap for Flexible Packaging

While reclosable flexible packaging is valued for helping maintain freshness and extending shelf life — a clear sustainability win — closures themselves have also evolved to further enhance sustainability. Even brands packaging non-food items can enhance their pouch’s sustainability with the right closure choice.

Once difficult to source, recyclable and compostable zipper and slider systems are now widely available, including options made with bio-based content, PCR materials, and designs compatible with paper-based flexible packaging.

Recyclable Closures with Added Value

Closures are not one-size-fits-all; thankfully, today’s reclosable solutions offer a wide range of feature-focused options. Since many equate sustainability with recyclability, a vast majority of closures on the market are made to deliver on that goal, as well as several other wish-list items for consumers and packagers, such as child-resistance, tamper-evident features, sensory audible-tactile feedback, closures with extra strong product-side holding force, and more.

Because many sustainable film structures are designed for recyclability, creating mono-material reclosable pouches that score well on sustainability metrics is more achievable than ever. Whether the package is destined for store drop-off or curbside recycling, there are closures available to help meet both sustainability targets and functional goals.

Bio-Based Recyclable and PCR Closures: Next-Level Sustainability for Flexible Packaging

For brands looking to go beyond traditional petrochemical-based PE, flexible packaging closures made from bio-based recyclable PE or post-consumer recycled (PCR) materials offer strong sustainability advantages.

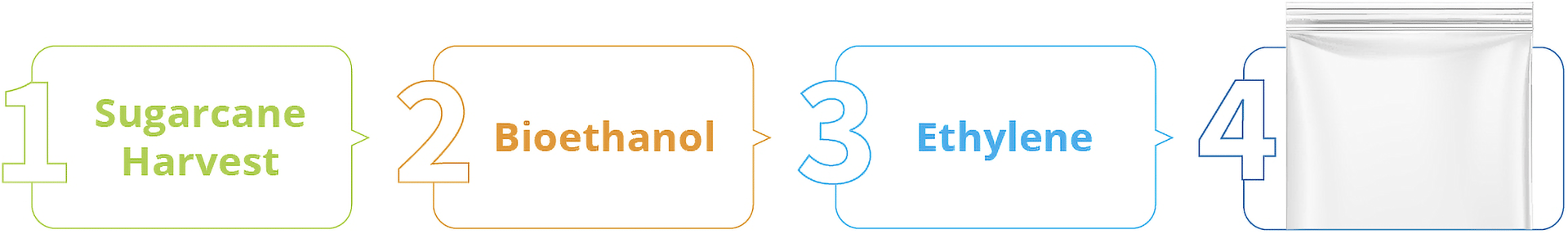

Bio-based PE, often sourced from plants like sugarcane, can meet performance standards for fully recyclable closures while reducing reliance on nonrenewable resources. Additionally, because the plant absorbs carbon from the atmosphere during growth, it contributes to carbon negativity in nature, further enhancing the environmental value of a bio-based recyclable closure.

The process of creating a bio-based, recyclable flexible packaging closure from sugarcane.

Similarly, closures made with PCR materials also help lower demand for virgin resources. By repurposing the materials that have already served their intended use, PCR supports the circular economy by putting the recycling streams to good use. These flexible packaging closures can also be recycled again, further extending their lifecycle.

Closures for Paper Pouches

Emerging paper-based pouches are targeted for plastic reduction and curbside bin recovery, accommodating a wide range of product applications and providing strong shelf appeal. There are new recyclable and bio-based closure options that work well with paper-based pouches — allowing brands to pair paper’s recyclable attributes with functional, consumer-friendly design.

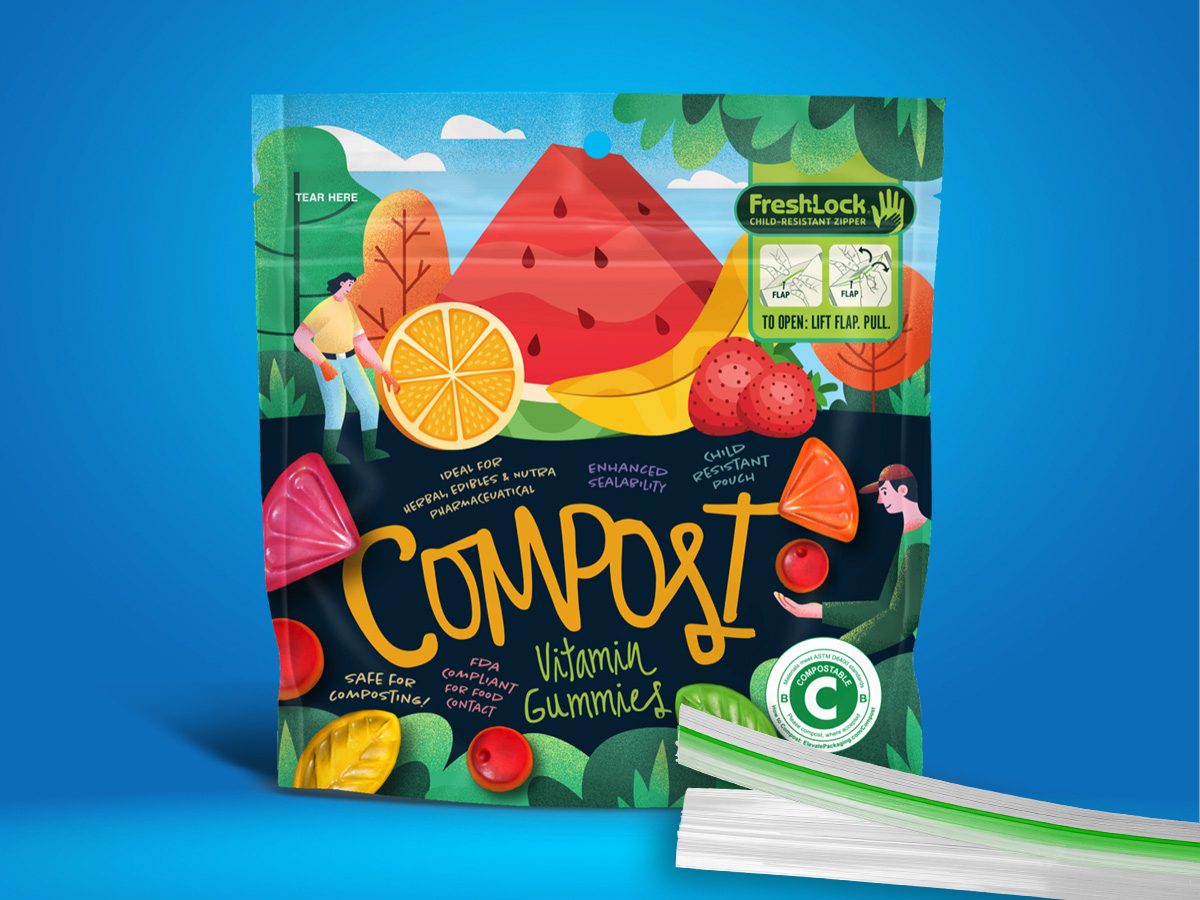

Compostable Closures for Every Flexible Package

While recyclable closures of all types are widely available, not all products are suited for recycling. Compostable packaging offers an alternative, and closures are available which provide options for both home compostable and industrial compostable pouches. These types of closures are designed to match the functionality of a polyethylene-based zipper but can biodegrade in a compostable environment at the end of their use. These closures are FDA-approved for food contact and designed for consumer convenience and functionality.

A vitamin gummies pouch incorporating a home-compostable, child-resistant, press-to-close zipper.

Reclosability Without Compromise

Sustainability comes in many forms, and packaging solutions should, too. Closure technology has advanced rapidly, giving converters and brands new ways to achieve packaging objectives, including performance, functionality, and differentiation.

No matter the goal, reclosability can be part of your package. Not sure where to start? Collaborate with sustainable flexible packaging suppliers. Many are actively working to offer new solutions for all types of flexible pouches, helping brands meet evolving sustainability targets and consumer needs.