Packaging Line Optimization in the Age of a Pandemic

Changes that occurred during COVID-19 and lessons learned.

By Kristen Kazarian, editor in chief

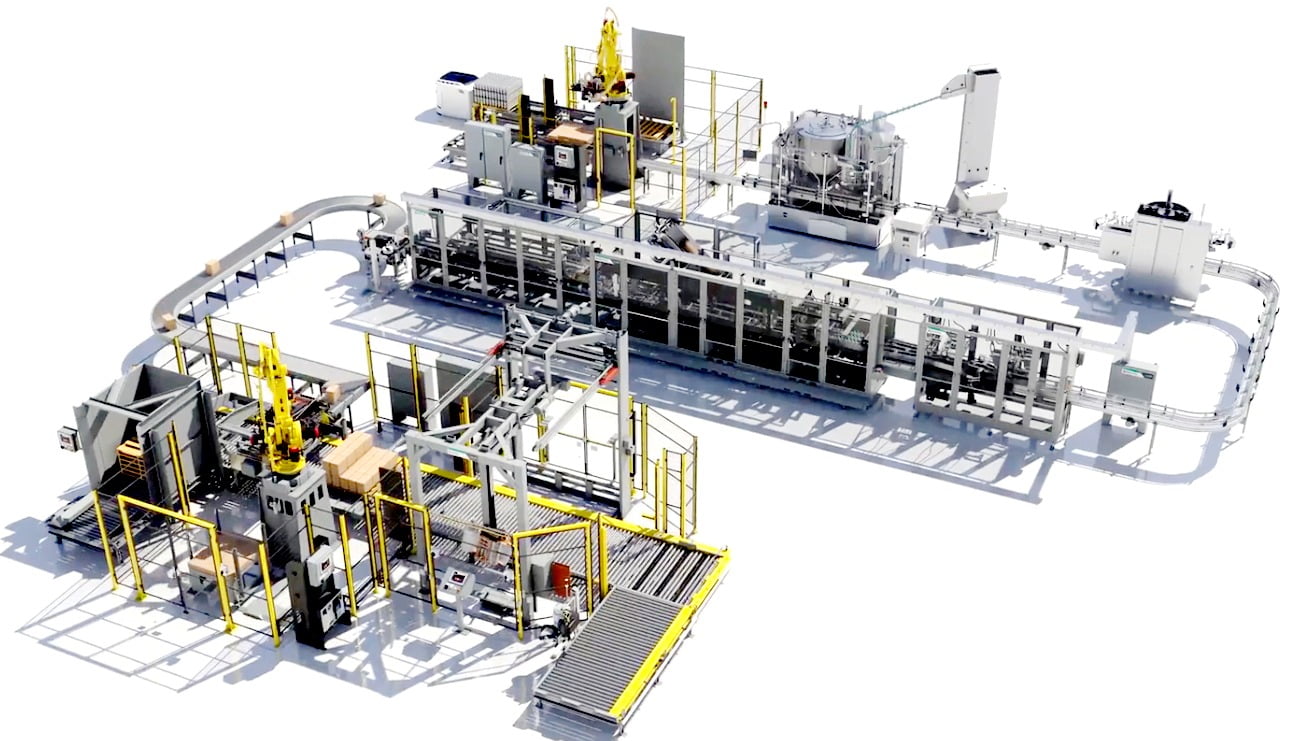

Brenton’s Integrated Medical System’s team is on the front line of support for Operation Warp Speed participants.

Photo courtesy of Brenton

There were many variables that affected how packaging lines were run — even the suppliers who have customers in consumer packaged goods companies (CPGs) felt the changes. We have social distancing rules, some plant floors with changed production lines (including facilities who added PPE to their schedules) and some labor issues with field service techs not being able to do their jobs 100%. So who did what and how did they fare?

We wanted to find out what occurred, how it changed and if we needed to focus on certain practices in the future, in case something like this pandemic happens again. So, Packaging Strategies reached out to some companies of varying roles in the industry — including Kelly Hawkinson, Focus Factory Manager at Brenton; Craig Souser, President & CEO, JLS Automation; Joe Luke, VP of Sales & Marketing at Reed Lane; and Chris Baum, Director of Sales Specialists, Veritiv; and Bob Neagle, Commercial Director, Digital Products and Services with Videojet.

If you think your company is the only one to have gone through trials and tribulations, read on to see how others have handled 2020.

See What Executives Say

Use the arrows to continue to the next section, or click on a theme below:

How has COVID-19 affected your operations?

Have you dealt with labor changes?

What have you learned over the past year, and what will you do differently in the future?

What are your tips to help in packaging line optimization?

For more on packaging lines, look at “5 Topics to Discuss with Your Packaging Line Intigrator” on our website.

Spotlight illustration by sorbetto / DigitalVision Vectors via Getty Images